Course Description

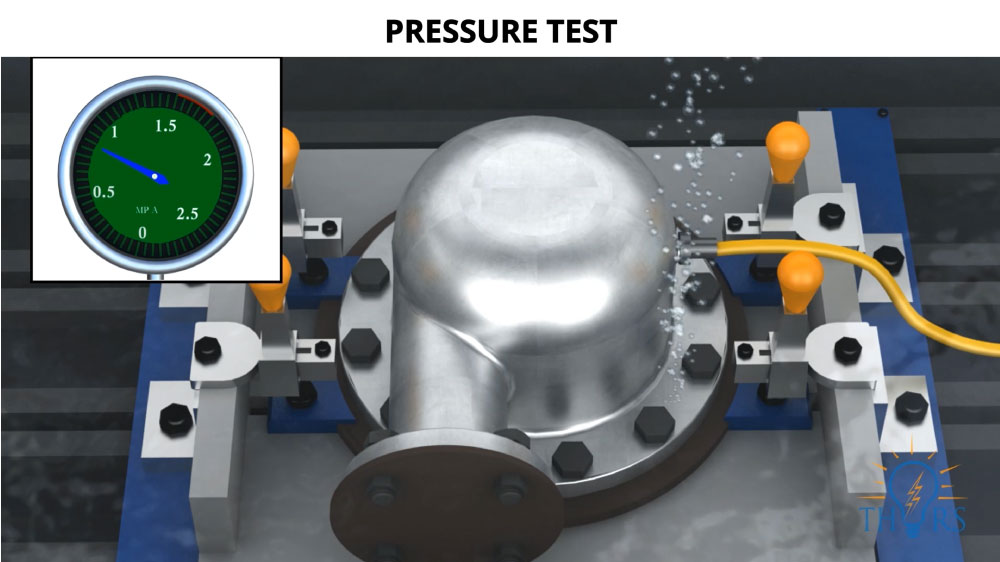

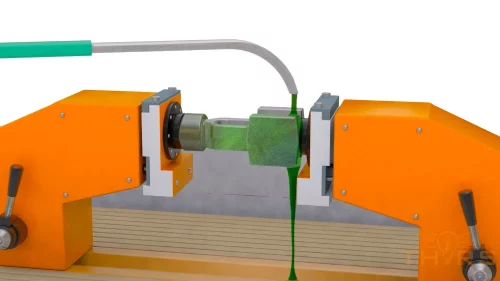

The Quality Inspection for Steel Castings course details some of the more common methods used to evaluate a steel casting for compliance to a customer’s specification requirements. Relevant for quality and inspection roles, this course focuses on the most common quality non-conformances observed during the visual inspection of steel castings and standard non-destructive testing (NDT) methods used for casting evaluation.

Who will benefit from this Steel Castings Quality Inspection course?

Foundries that pour steel; Customers who purchase steel castings; Organizations that sell material, equipment, and services to steel foundries.

Course Classification

*THORS uses the Bloom’s Taxonomy Methodology for our course development.

Certificate Awarded for Quality Inspection for Steel Castings

*upon successful completion

Related Posts

eLearning Support for On-Site Training

eLearning has emerged as a revolutionary force in the realm of learning and professional development, evolving into an imperative tool in today’s competitive landscape. The

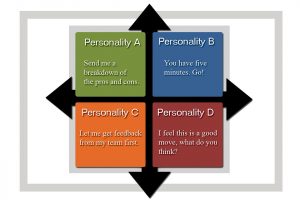

Knowing Customer’s Personality Style Adds Value

Maybe you think the value is obvious. If you can speak the same “language” as the person you are talking with, you can build trust

Boosting Employee Engagement in eLearning

Introduction In the realm of modern workplaces, boosting employee engagement in eLearning has become a pivotal factor in fostering productivity, job satisfaction, and overall organizational