Course Description

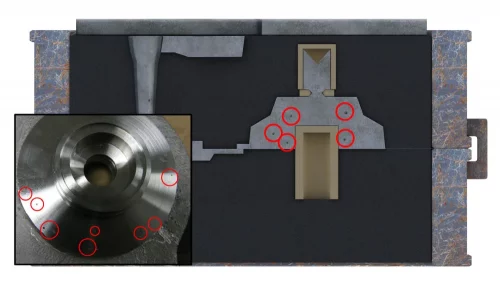

Green Sand Defect Analysis is an examination of the appearance, root causes, and potential preventative measures for defects common to green sand systems. Presented in THORS’ highly visual and interactive learning format, this course is designed to improve the ability of foundry employees to recognize and correct green sand related defects.

Who will benefit from this Green Sand Defects course?

Companies, individuals, or educational institutions that require an understanding of green sand defect analysis.

Course Classification

*THORS uses the Bloom’s Taxonomy Methodology for our course development.

Certificate Awarded for Green Sand Defect Analysis

*upon successful completion

Related Posts

Enhancing Workforce Development with THORS eLearning Solutions

Workforce development programs are designed to equip employees with the knowledge and skills necessary to excel in their roles and adapt to the evolving demands

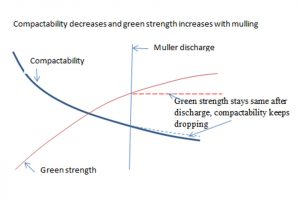

How to Control Compactability of Sand?

Manufacturing industry veteran Al Alagarsamy shares a functional tip for sand production. He explains the importance of sand compactability and the factors affecting it. What

Manufacturing Sustainability in Metal Casting Industries

Metal casting is the manufacturing process of pouring molten metal into a mold to create a required shape. While metal casting has been an important