Course Description

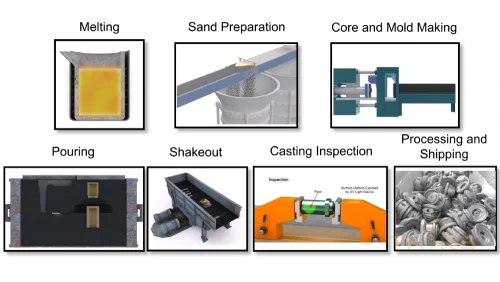

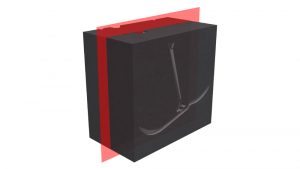

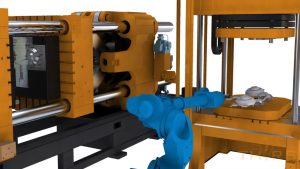

Bonded Sand Fundamentals is an introduction to bonded sand molding processes, including the mold and core preparation, pouring, solidification, and separation of metal parts. Presented in THORS’ highly visual and interactive learning format, this course will help foundry employees become familiar with the important equipment and terminology associated with their profession.

Who will benefit from this Bonded Sand course?

Companies, individuals, or educational institutions that produce castings from bonded sand molds.

Course Classification

*THORS uses the Bloom’s Taxonomy Methodology for our course development.

Certificate Awarded for Bonded Sand Fundamentals

*upon successful completion

Related Posts

Manufacturing Sustainability in Metal Casting Industries

Metal casting is the manufacturing process of pouring molten metal into a mold to create a required shape. While metal casting has been an important

How THORS Courses Helped a Mechatronics Student in Germany

Sasshank is an international student attending University in Germany where he studies mechatronics engineering. He was born in Tamil Nadu, where he attended various schools

Upskilling in the Manufacturing Industry with THORS

In today’s rapidly evolving manufacturing industry, staying up to date with the latest technologies and processes is crucial to remaining competitive. Upskilling in the manufacturing industry