Course Description

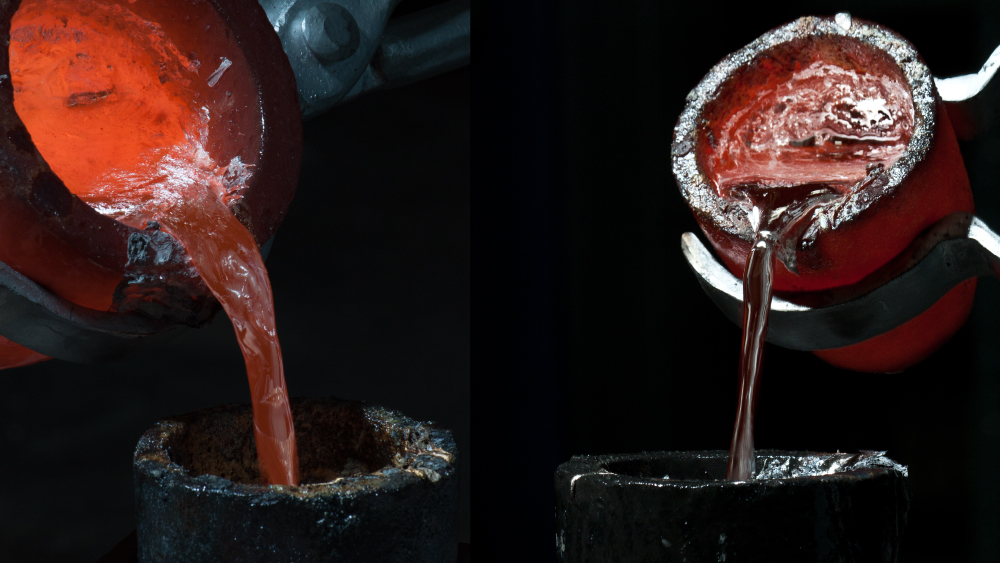

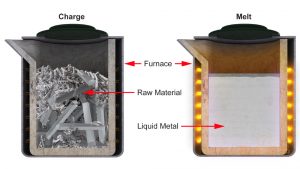

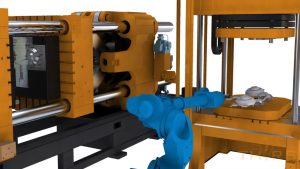

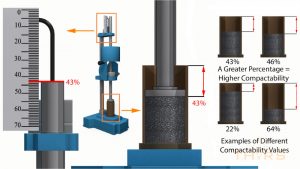

Aluminum Melting Fundamentals examines the equipment, processes, and general terminology associated with aluminum melting and casting foundries. Presented in THORS’ highly visual and interactive format, this course provides learners with a variety of important topics for this expanding industry. From learners who are new to aluminum casting industries, to seasoned veterans, there is relevant knowledge for everyone in this course.

Who will benefit from this Aluminum Melting course?

Companies, individuals, or educational institutions that are required to properly melt, modify, and pour aluminum castings.

Course Classification

*THORS uses the Bloom’s Taxonomy Methodology for our course development.

Certificate Awarded for Aluminum Melting Fundamentals

*upon successful completion

Related Posts

Benefits of eLearning in Manufacturing

In the world of manufacturing, training is essential. Every employee needs to understand how to use equipment, follow procedures, and maintain quality standards. With the advent

eLearning Support for On-Site Training

eLearning has emerged as a revolutionary force in the realm of learning and professional development, evolving into an imperative tool in today’s competitive landscape. The

Green Sand: A Classic Casting Recipe

Casting Chronicles The history of humanity is defined by man’s relationship with the material world. Man’s ability to make tools from metals has changed our