Course Description

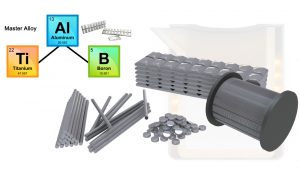

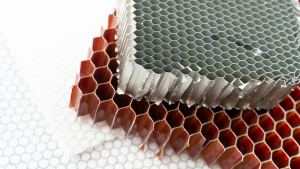

Aluminum Casting Fundamentals introduces the learner to the properties, chemistry, and processes associated with casting aluminum components. The common aluminum casting defects are also included to familiarize the learners with real world problems that may arise in the production of aluminum casted parts. Presented in the THORS visual and interactive format, this course is relevant for learners who are new to the industry, as well as experienced learners that require a deeper knowledge of aluminum casting microstructure, casting grades, and microstructure control.

Who will benefit from this Aluminum Casting course?

Foundries that melt aluminum; Customers who procure aluminum castings; Organizations that sell raw materials, equipment, and services to aluminum foundries.

Course Classification

*THORS uses the Bloom’s Taxonomy Methodology for our course development.

Certificate Awarded for Aluminum Casting Fundamentals

*upon successful completion

Related Posts

Women in Manufacturing: An Interview with Kavita Krishnamurthy

As part of a tribute to women in manufacturing, we at THORS eLearning Solutions decided to showcase one of our own, Kavita Krishnamurthy. Kavita is

5 signs you should invest in effective workforce training

In today’s constantly changing marketplace, the importance of workforce training has never been greater. Workforce training has the ability to not only increase workforce efficiency

A Differentiated Learning Approach: A Closer Look at THORS

In the wide landscape of learning methodologies, the pursuit of engaging and effective learning approaches has been ongoing. Among the myriad approaches, a differentiated learning