Course Description

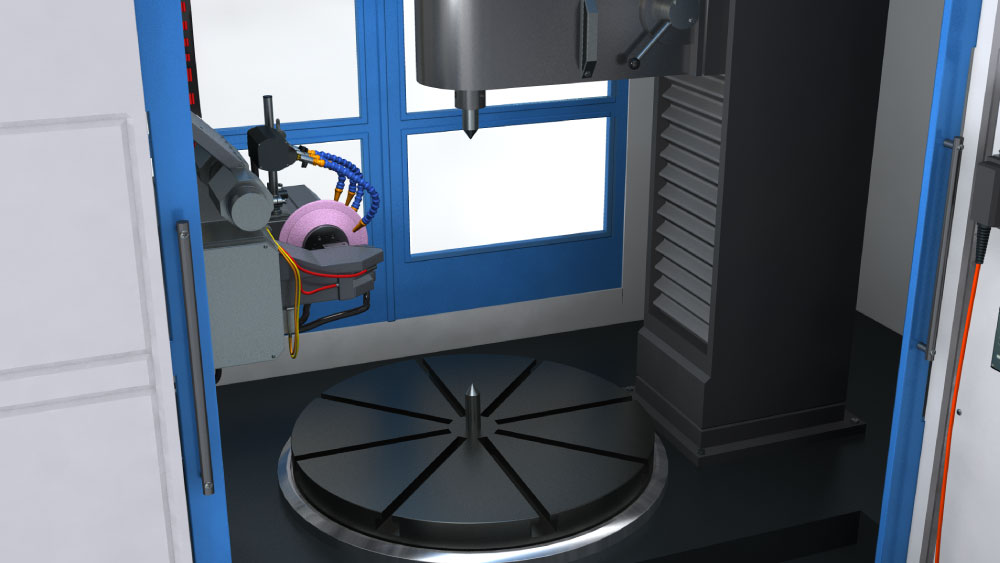

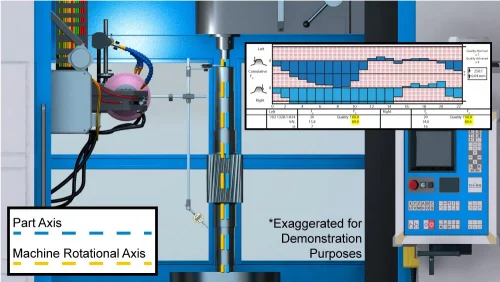

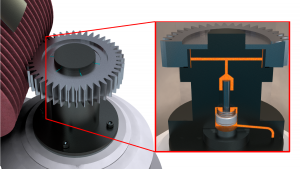

Gears: Cylindrical Gear Manufacturing Troubleshooting is a highly visual course designed for an advanced learner who has prior knowledge of gear terminology, gear manufacturing, and gear chart interpretation. In this course, learners are introduced to the common manufacturing errors that manifest themselves on gear charts. The course then provides an understanding of the potential root causes of the errors, followed by a discussion on the tips and techniques that can be used to correct the errors.

Who will benefit from this Cylindrical Gear Manufacturing Troubleshooting course?

Gear Manufacturing Engineers, Gear Cutting & Gear Grinding Machinists, Quality Inspectors, and any learner who must be familiar with the common gear manufacturing errors and how to correct them.

Course Classification

*THORS uses the Bloom’s Taxonomy Methodology for our course development.

Certificate Awarded for Gears: Cylindrical Gear Manufacturing Troubleshooting

*upon successful completion

Related Posts

Training Programs are Critical to Attracting and Retaining Talent

In today’s rapidly changing business landscape, organizations face a unique set of challenges in finding, hiring, and retaining top talent. The tight labor market has

Enhancing Workforce Development with THORS eLearning Solutions

Workforce development programs are designed to equip employees with the knowledge and skills necessary to excel in their roles and adapt to the evolving demands

5 Reasons Why a Culture of Learning can Lead to Success

Learning is continuous. After all, there are always new skills to learn and techniques to adopt. A culture of learning in an organization can also