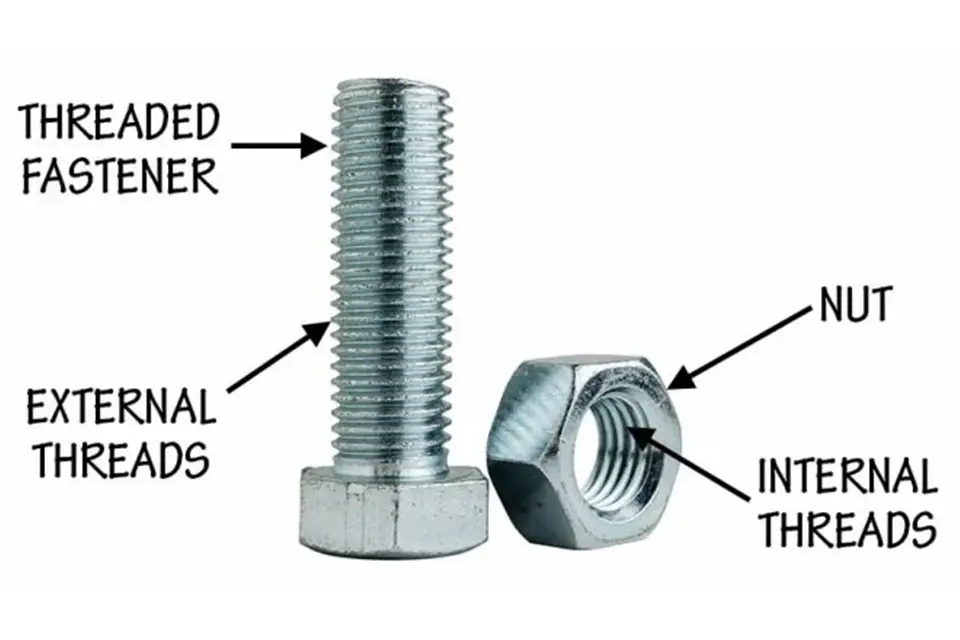

There is much to know about the protruding ridges that spiral around the diameter of a threaded fastener, known as external threads, especially for anyone who designs, manufactures, or purchases threaded fasteners. While engineers might design threads with dozens, even hundreds of dimensional segments that assist in the precise manufacturing of fasteners, a better understanding of thread parts can be acquired by examining just a few key terms.

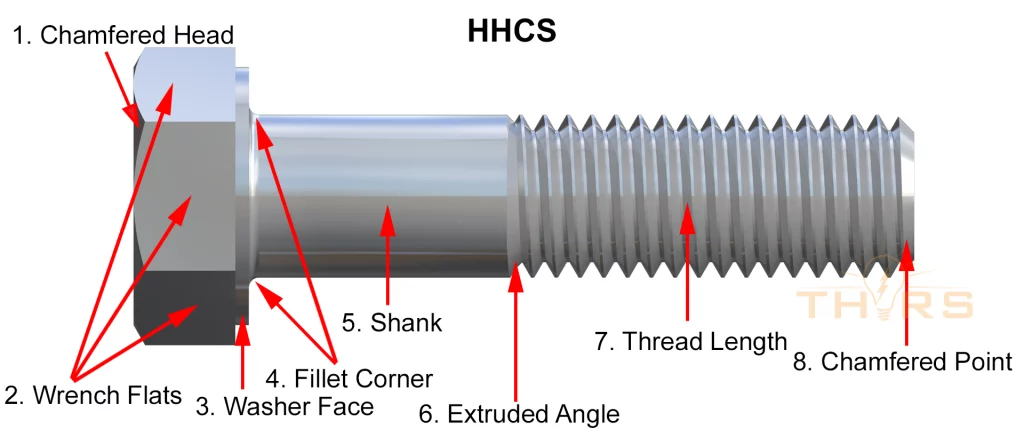

Threaded Fastener Parts

- Chamfered Head

Chamfered heads have the sharp corners beveled to produce angled surfaces, which serves to prevent human injury as well as permit easier access to the wrench flats for a wrench or socket to tighten or loosen the fastener.

- Wrench Flats

Wrench flats are the sides of a fastener’s head. The flat surfaces provide a solid connection for tightening the fastener with a wrench or socket.

- Washer Face

A washer face is located just beneath the head of some threaded fasteners and provides a thicker surface area for the tension to be distributed across. Additionally, washer faces prevent the corners of the fastener’s head from digging into the surface that it rests against.

- Fillet Corner

A fillet corner is a rounded angle just beneath the head of an HHCS. Fillet corners add strength to the head and provide a transition from the fastener’s head to its shank.

- Shank

The shank is a portion of a threaded fastener that is smooth and distinct from the threads. The shank is generally the location where the diameter of a fastener is measured.

- Extruded Angle

An extruded angle is a transitional area formed between the end of a threaded fastener’s shank and where the threads begin.

- Thread Length

Thread length is the extent that threads cover the body of a threaded fastener, as distinct from the shank.

- Chamfered Point

Chamfered points are tapered ends that make it easier for external threads to engage a set of internal threads.

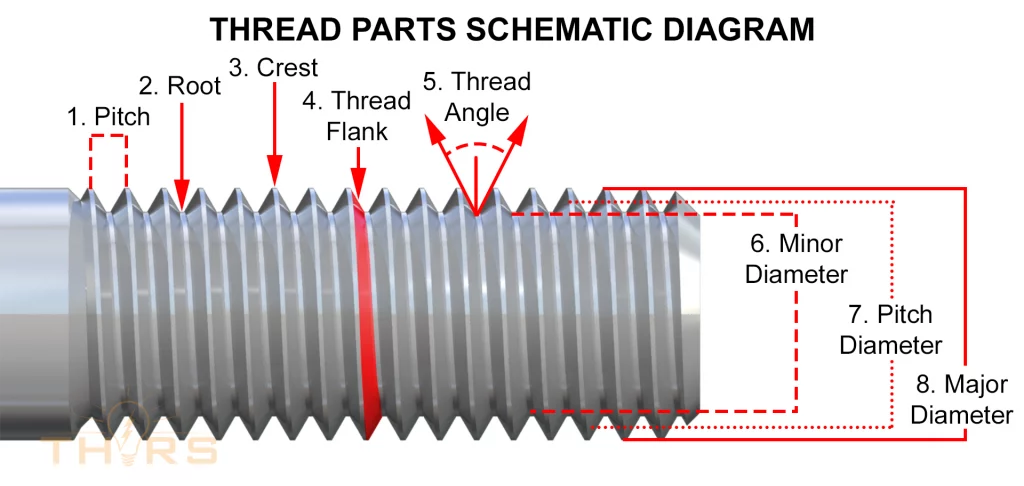

Thread Terminology

- Pitch

Pitch, or thread pitch, is the distance between two adjacent thread crests, which should be a consistent distance between all threads on a fastener. This applies to the metric system. If the fastener is Standard, or Imperial, Threads Per Inch (TPI) is the classification.

- Root

The root, or thread root, is the lowest point between two threads of a threaded fastener.

- Crest

The crest, or thread crest, is the highest peak of a threaded fastener.

- Thread Flank

The thread flank refers to the angled slopes or sides of an individual thread on a fastener. Because fastener threads are generally triangle-shaped, the flank could be imagined as the two exposed sides of a triangle that meet at the thread crest.

- Thread Angle

The thread angle, angle of threads, or flank angle is the degree formed between two threads. It has been standardized for most threaded fasteners at 60°, because this angle provides a connection that is both secure and yet easily assembled or disassembled when paired with internal threads.

- Minor Diameter

The minor diameter is the narrowest possible diameter of a fastener, observed at the lowest point between the threads.

- Pitch Diameter

The pitch diameter is located approximately in the middle of an individual thread and is consistent across all the threads on a fastener as if an imaginary cylinder existed directly in between the major and minor diameters.

- Major Diameter

The major diameter is the widest possible diameter of a threaded fastener, observed at the tips of the threads.

Interested in increasing your understanding of Fasteners? THORS offers multiple Fastener courses including, Threaded Fastener Terminology and Components, Threaded Fastener Specifications, and Threaded Fastener Testing and Defects.