Introduction

In today’s technically advanced world, there is a need for sophisticated products that use components like resistors, transistors, and capacitors, to name a few. Electronic assembly is the backbone of the production line, ensuring that electronic devices are assembled accurately and efficiently. Efficient electronic assembly processes contribute to cost-effectiveness by minimizing waste and optimizing production throughput. The role of electronic assemblers in electronic manufacturing who are involved in piecing the electronic components together to create a finished electronic product are essential to the process. An electronic assembler interprets instructions, assembles electronic components using the right tool, tests for functionality and quality standards, checks conformity to specifications, and services electronic products in the production line.

What it Takes for the Role of an Electronic Assembler

There is no particular qualification for the role of an electronic assembler other than completing secondary school. However, pursuing apprenticeships or on-the-job training programs to gain practical experience in electronic assembly techniques can help in the long run. Additionally, e-learning courses offer valuable opportunities for aspiring assemblers to enhance their skills and knowledge in this field, often covering topics such as introduction to electronics terminology, reading engineering drawings, Printed Circuit Board (PCB) basics, and safety protocols.

An Electronic Assembler’s Typical Day

A typical day for an electronic assembler involves several tasks and responsibilities, which may vary according to the specific industry and the type of electronic product.

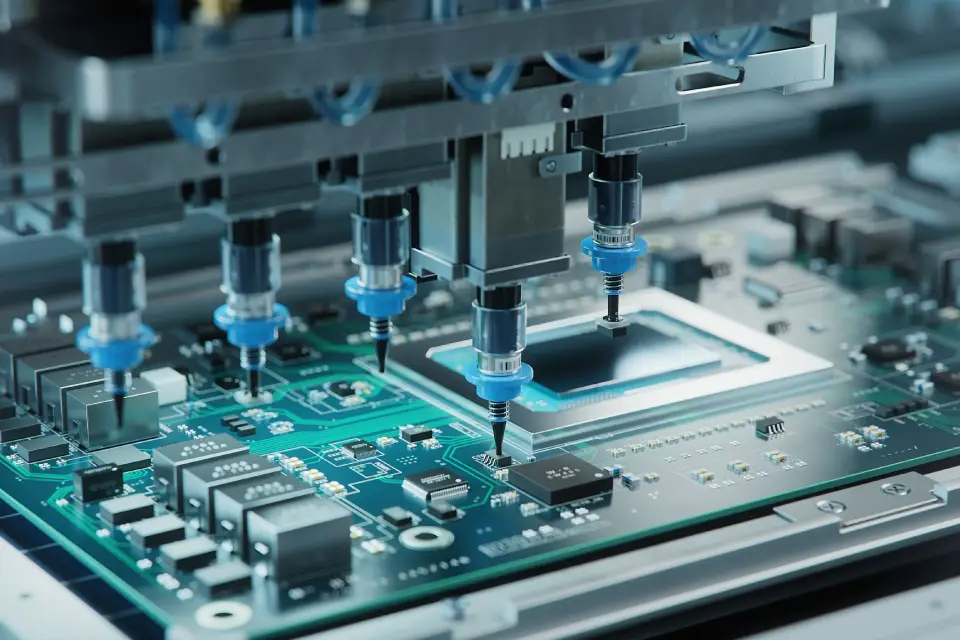

In general, electronic assemblers begin their day by reviewing work orders and engineering drawings to understand the assembly requirements for the day. Then, they proceed to gather the necessary components and materials for the assembly process. Throughout the day, electronic assemblers use soldering irons, wiring tools, or control automated robots and systems to assemble electronic components, following precise instructions to ensure accuracy and quality. During manual assembly, electronic assemblers utilize tools such as pliers, soldering irons, screwdrivers, wrenches, and power drills. In automated assembly, the focus shifts to programming robots and computers tasked with assembling electronic components.

Electronic assemblers ensure the alignment of electronic components in a PCB or other substrate according to the circuit design. Securing the components and creating electrical connections using solder and wires are also an important task of the electronic assembler. Soldering helps hold the electronic components in place and also helps establish electrical connections between the board and the components as well as between other components on the board. Wiring is also done to enable proper routing as per specifications. They collaborate with colleagues and supervisors as needed, troubleshoot any issues that may arise during assembly, and make adjustments or repairs to meet quality standards. Attention to detail is critical to catching any discrepancies or errors in the assembly process, ensuring the quality and reliability of the finished product. Dexterity is also essential for handling small components and performing intricate tasks with precision.

Compensation for an Electronic Assembler

The compensation and wages of an electronic assembler depend on the size of the company, location, and the type of electronic product produced. The average salary of an electronic assembler is $36,000 – $51,000 per year. The average hourly wage in the United States is $16 -$20.

Scope of the Industry for an Electronic Assembler

As technology advances, the role of electronic assemblers undergoes continual evolution. To remain competitive, electronic assemblers must keep pace with the latest industry trends. As an electronic assembler, you can become a through-hole assembler, surface mount technology assembler, cable and harness assembler, panel assembler, or prototype assembler based on the type of work and the nature of the electronic components.

Through-hole Assembler: A through-hole assembler manually inserts electronic components through predrilled holes on circuit boards, followed by soldering to secure them in place.

Surface Mount Technology Assembler: A surface mount technology assembler utilizes either a pick-and-place machine or tweezers to precisely position and solder tiny surface-mounted electronic components onto circuit boards, ensuring accuracy and efficiency in the assembly process.

Cable and Harness Assemblers: Specialize in assembling cables and harnesses, meticulously connecting wires, cables, and connectors according to wiring diagrams and specifications, ensuring proper electrical connections and cable management.

Panel Assemblers: A panel assembler focuses on assembling control panels and electronic enclosures, mounting various components such as switches, indicators, and displays onto panels or enclosures, and wiring them according to schematic diagrams.

Prototype Assembler: A prototype assembler is involved in the early stages of product development, developing prototype electronic assemblies and adjusting assembly processes to reach the desired quality.

Conclusion

If you are patient, work well with others in close quarters, and take pride in delivering top-notch workmanship, a career as an electronic assembler could offer you a rewarding experience. In addition to these qualities, being detail-oriented and having a knack for problem-solving are also valuable assets in this field.