Course Description

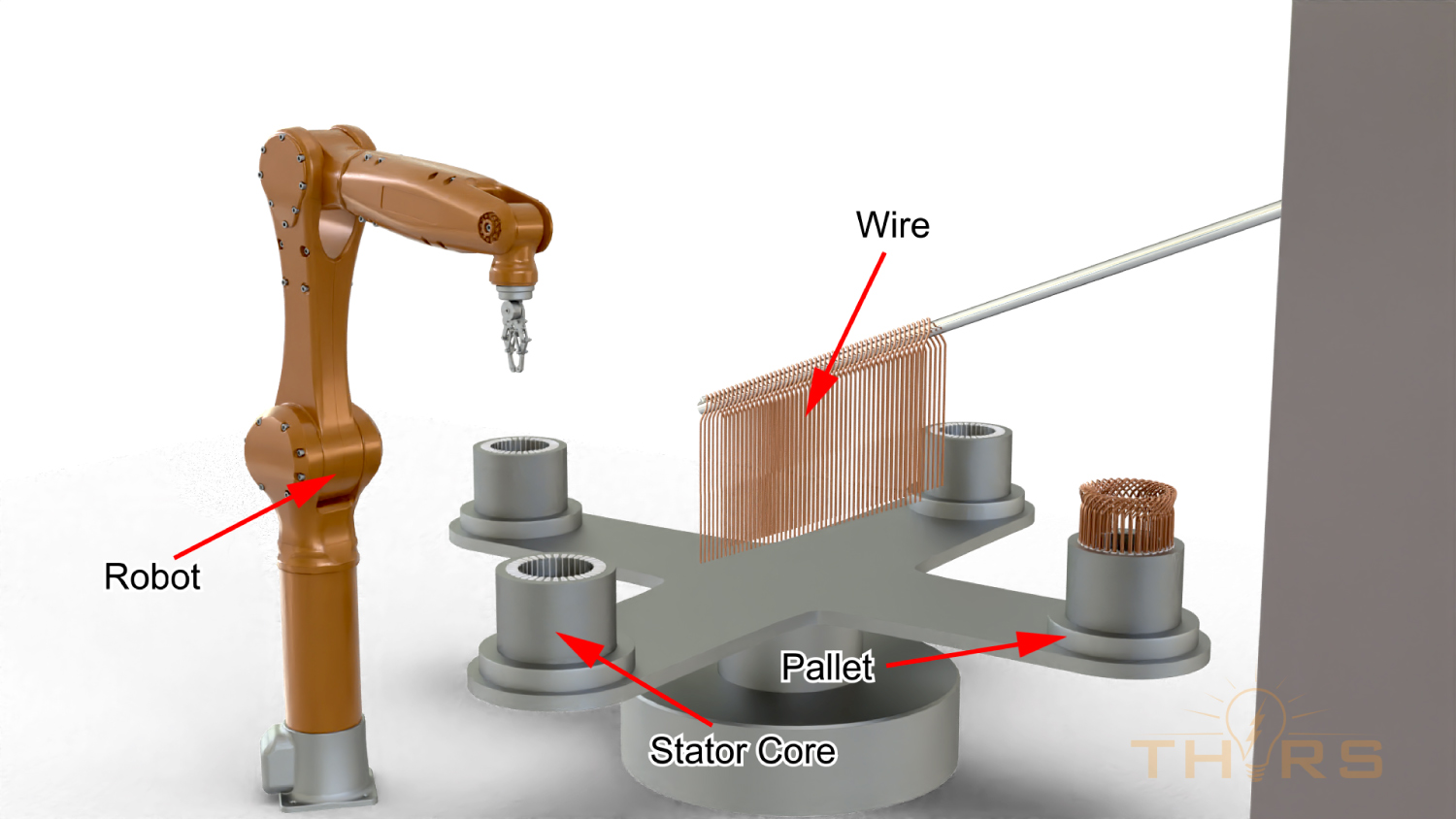

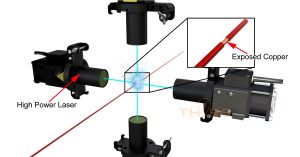

The THORS Traction Motor Stator Assembly Process course explains the various processes in front end assembly and the back end assembly of a stator that is used in a traction motor. The course progresses through the processes beginning with basic copper wire forming and bending before being inserted into the stator laminates. Then, the wires are welded, receive a varnish application and epoxy bath, and the final components are added to the stator. Finally, the learner is introduced to the electrical testing methods that are completed before the stator can be shipped out of the assembly plant.

Who will benefit from this Traction Motor Stator Assembly course?

Sales, Purchasing, Manufacturing Engineering, Quality, and Design Engineering

Course Classification

*THORS uses the Bloom’s Taxonomy Methodology for our course development.

Certificate Awarded for Traction Motor Stator Assembly Process

*upon successful completion

Related Posts

How THORS Courses Helped a Mechatronics Student in Germany

Sasshank is an international student attending University in Germany where he studies mechatronics engineering. He was born in Tamil Nadu, where he attended various schools

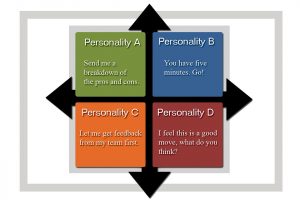

Knowing Customer’s Personality Style Adds Value

Maybe you think the value is obvious. If you can speak the same “language” as the person you are talking with, you can build trust

The Essential Skills of Modern Purchasing Professionals

In my professional career that spans more than three decades, I have had the privilege of working closely with purchasing. I can attest to the