Course Description

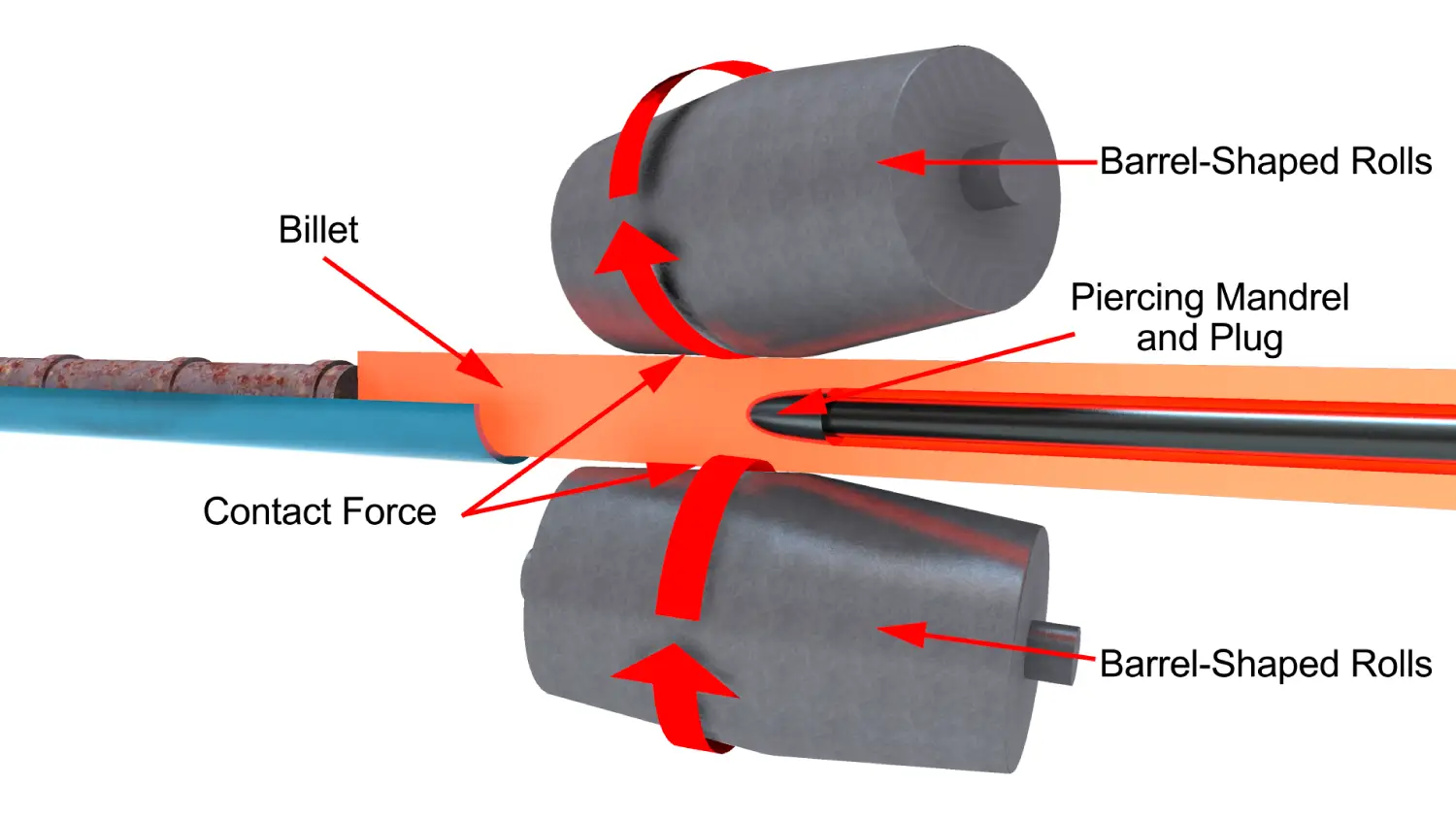

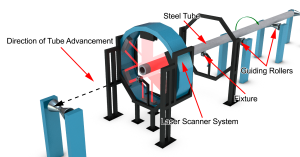

The THORS Steel Tubing Production course offers an interactive learning experience that allows learners to gain an in-depth understanding of production, inspection and testing of steel tubes. This course elaborates on the two primary production methods of steel tubes, namely seamless production and welded production. The defects found during steel tubing production and the respective inspection methods are explored in detail.

Who will benefit from this steel tubing production course?

Sales, Purchasing, Manufacturing Engineering, Quality, and Design Engineering

Course Classification

*THORS uses the Bloom’s Taxonomy Methodology for our course development.

Certificate Awarded for Steel Tubing Production

*upon successful completion

Related Posts

How Can THORS Help Enhance Your College Education?

THORS Academy can help enhance your college education in a number of ways. Imagine being in a college class and being told you have a

Innovations in Steel Tubing Production

The steel tubing industry is witnessing a remarkable transformation, driven by innovations in the field. The steel tubing industry has long been the backbone of

The Role of Virtual Reality in Technical Training

In the rapidly evolving landscape of technology and industry, virtual reality (VR) in technical training is leading a revolutionary transformation in how professionals are trained.