Course Description

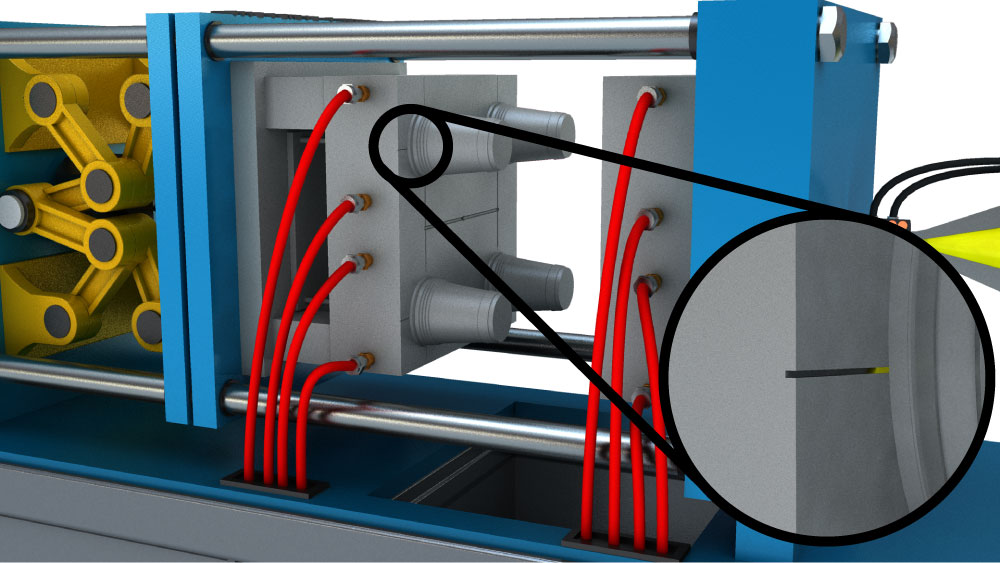

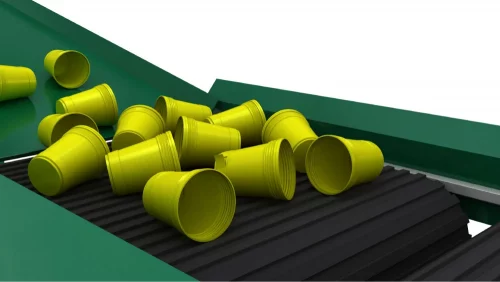

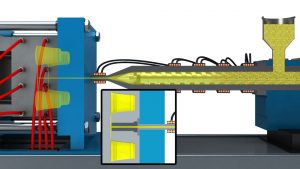

Polymers: Injection Molding Troubleshooting is an informative, advanced-level course on troubleshooting molded part defects created during the injection molding process. In this course, learners are introduced to the main problem areas that may affect molded parts during the injection molding process, including the mold, machine, material, and process. The course then discusses potential troubleshooting strategies, followed by a discussion of the most common defects that may affect a molded part. Learners in quality, manufacturing, sales or related, and research and development in the industry will find value in this course.

Who will benefit from this Injection Molding Troubleshooting course?

R&D new hires, manufacturing process engineers, sales reps – technical sales, account managers, product developers, tech service, product managers, quality managers.

Course Classification

*THORS uses the Bloom’s Taxonomy Methodology for our course development.

Certificate Awarded for Polymers: Injection Molding Troubleshooting

*upon successful completion

Related Posts

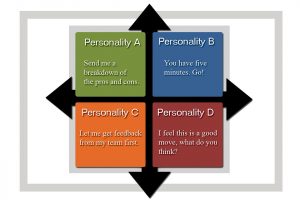

Knowing Customer’s Personality Style Adds Value

Maybe you think the value is obvious. If you can speak the same “language” as the person you are talking with, you can build trust

eLearning Support for On-Site Training

eLearning has emerged as a revolutionary force in the realm of learning and professional development, evolving into an imperative tool in today’s competitive landscape. The

Women in Manufacturing: An Interview with Kavita Krishnamurthy

As part of a tribute to women in manufacturing, we at THORS eLearning Solutions decided to showcase one of our own, Kavita Krishnamurthy. Kavita is