Course Description

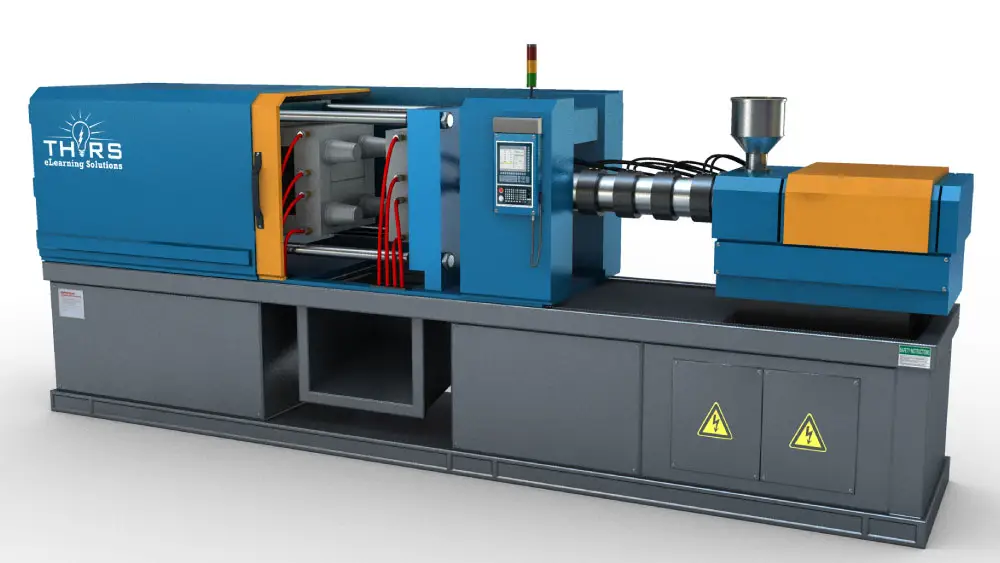

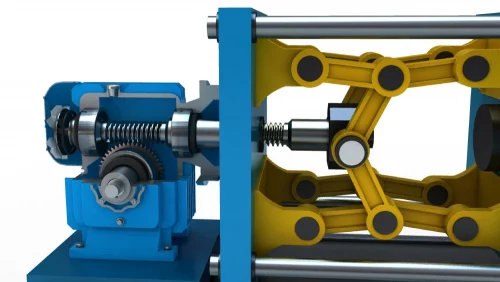

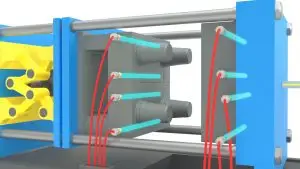

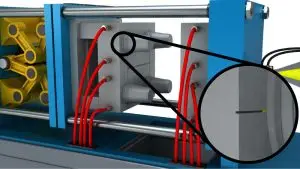

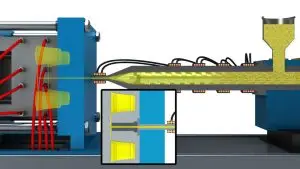

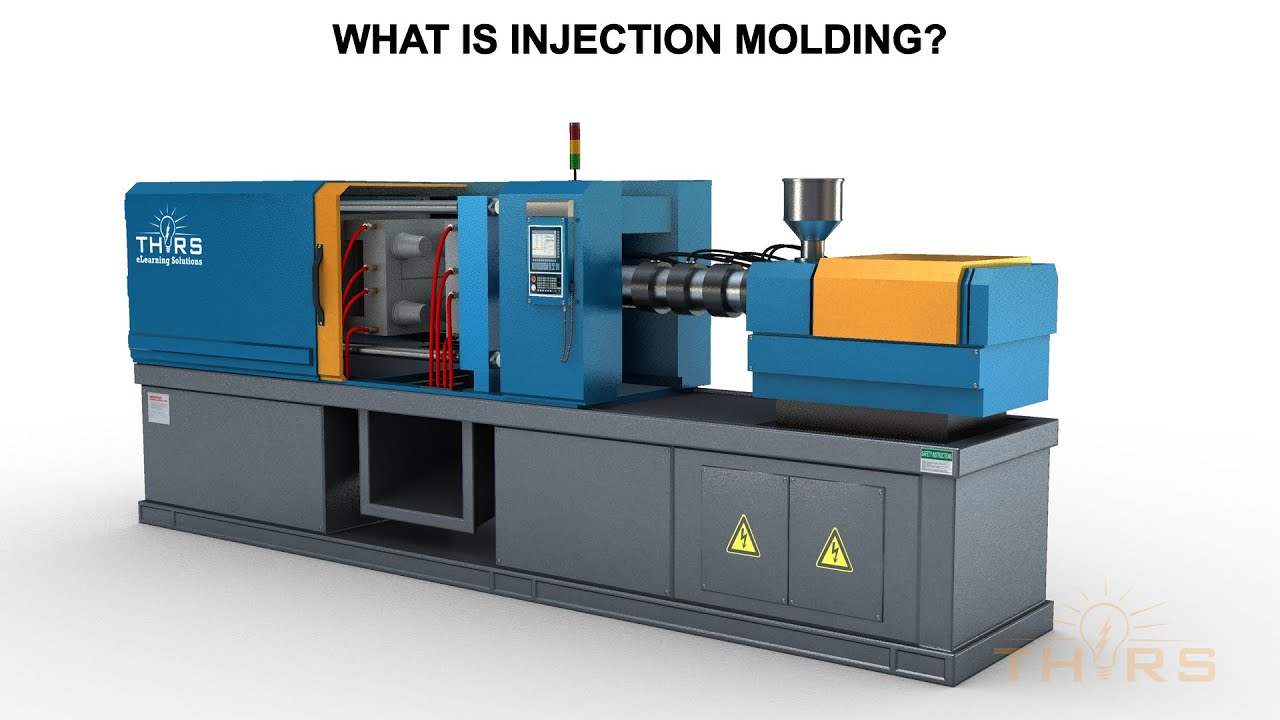

The Polymers: Injection Molding Terminology course is an informative, entry-level introduction to the key injection molding terminology. In this course, learners are presented with the basics of injection molding, the types of injection molding machines and equipment used, as well as the mold tooling components. Learners in quality, manufacturing, sales or related, and research and development in the industry will find value in this course.

Who will benefit from this Injection Molding course?

R&D new hires, manufacturing process engineers, sales reps – technical sales, account managers, product developers, tech service, product managers, quality managers.

Course Classification

*THORS uses the Bloom’s Taxonomy Methodology for our course development.

Certificate Awarded for Polymers: Injection Molding Terminology

*upon successful completion

Related Posts

The Role of Virtual Reality in Technical Training

In the rapidly evolving landscape of technology and industry, virtual reality (VR) in technical training is leading a revolutionary transformation in how professionals are trained.

How THORS Courses Helped a Mechatronics Student in Germany

Sasshank is an international student attending University in Germany where he studies mechatronics engineering. He was born in Tamil Nadu, where he attended various schools

Is Your Issue a Skills Gap or a Knowledge Gap?

You may have received a call to action to address the skills gap, which might feel making a bridge across the Grand Canyon with a