Course Description

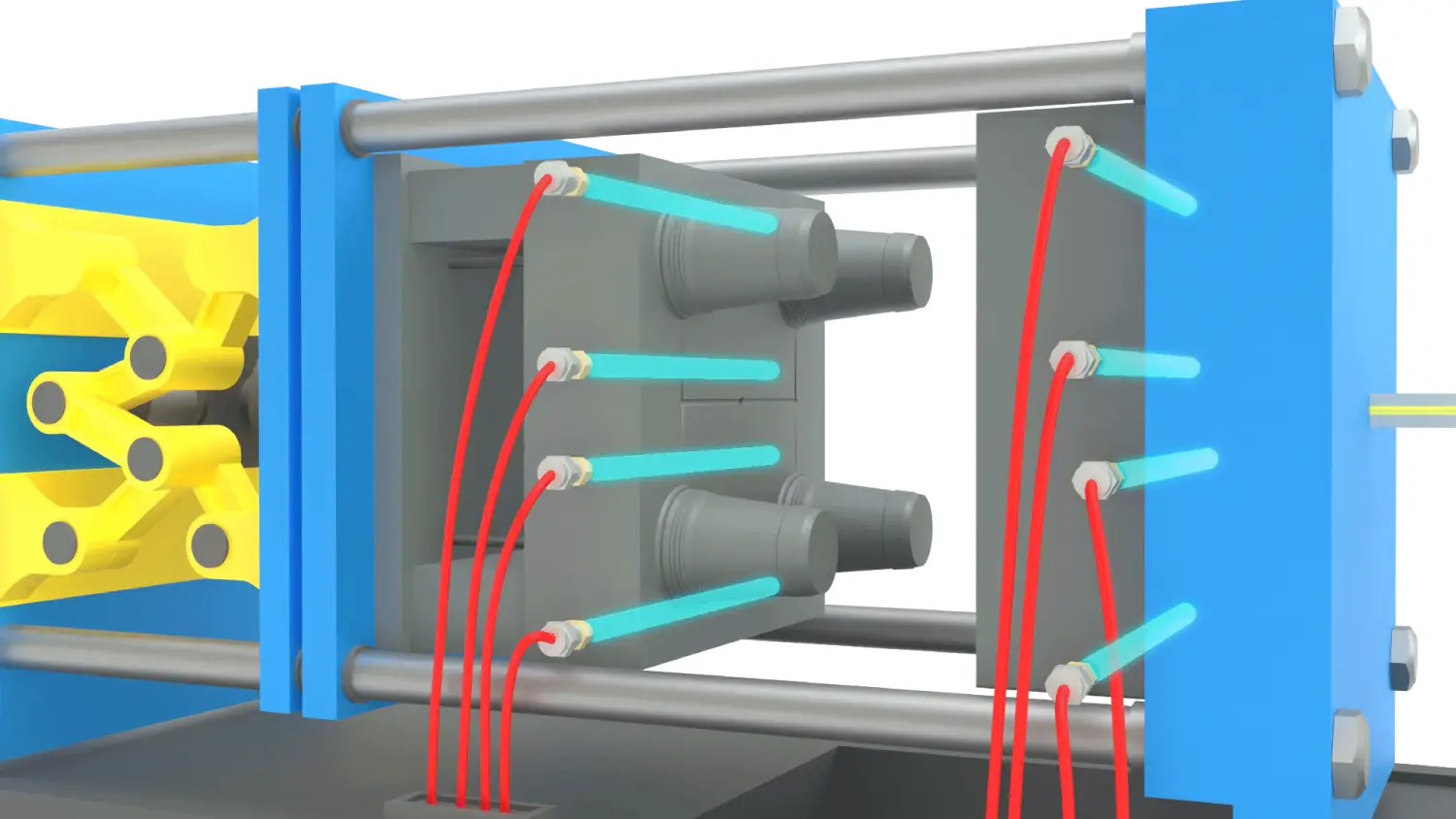

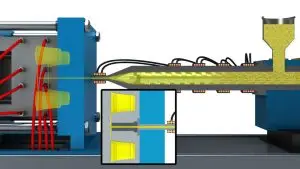

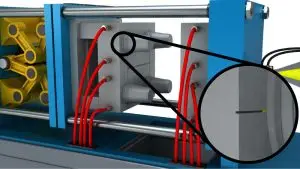

The THORS Injection Molding Design Fundamentals is an advanced-level course focused on mold design for the injection molding process where learners are introduced to part design and mold design considerations. The course also provides an interactive learning experience on molding machine selection factors, mold filling analysis, and mold functional systems design.

Who will benefit from injection molding design fundamentals course?

R&D new hires, manufacturing process engineers, sales reps – technical sales, account managers, product developers, tech service, product managers, quality managers

Course Classification

*THORS uses the Bloom’s Taxonomy Methodology for our course development.

Certificate Awarded for Injection Molding Design Fundamentals

*upon successful completion

Related Posts

How THORS Courses Helped a Mechatronics Student in Germany

Sasshank is an international student attending University in Germany where he studies mechatronics engineering. He was born in Tamil Nadu, where he attended various schools

5 Ways to Reduce Human Errors in Manufacturing

We cannot change the human condition, but in manufacturing we can certainly improve the way people work, where they work, and what systems they use.

Training Programs are Critical to Attracting and Retaining Talent

In today’s rapidly changing business landscape, organizations face a unique set of challenges in finding, hiring, and retaining top talent. The tight labor market has