Course Description

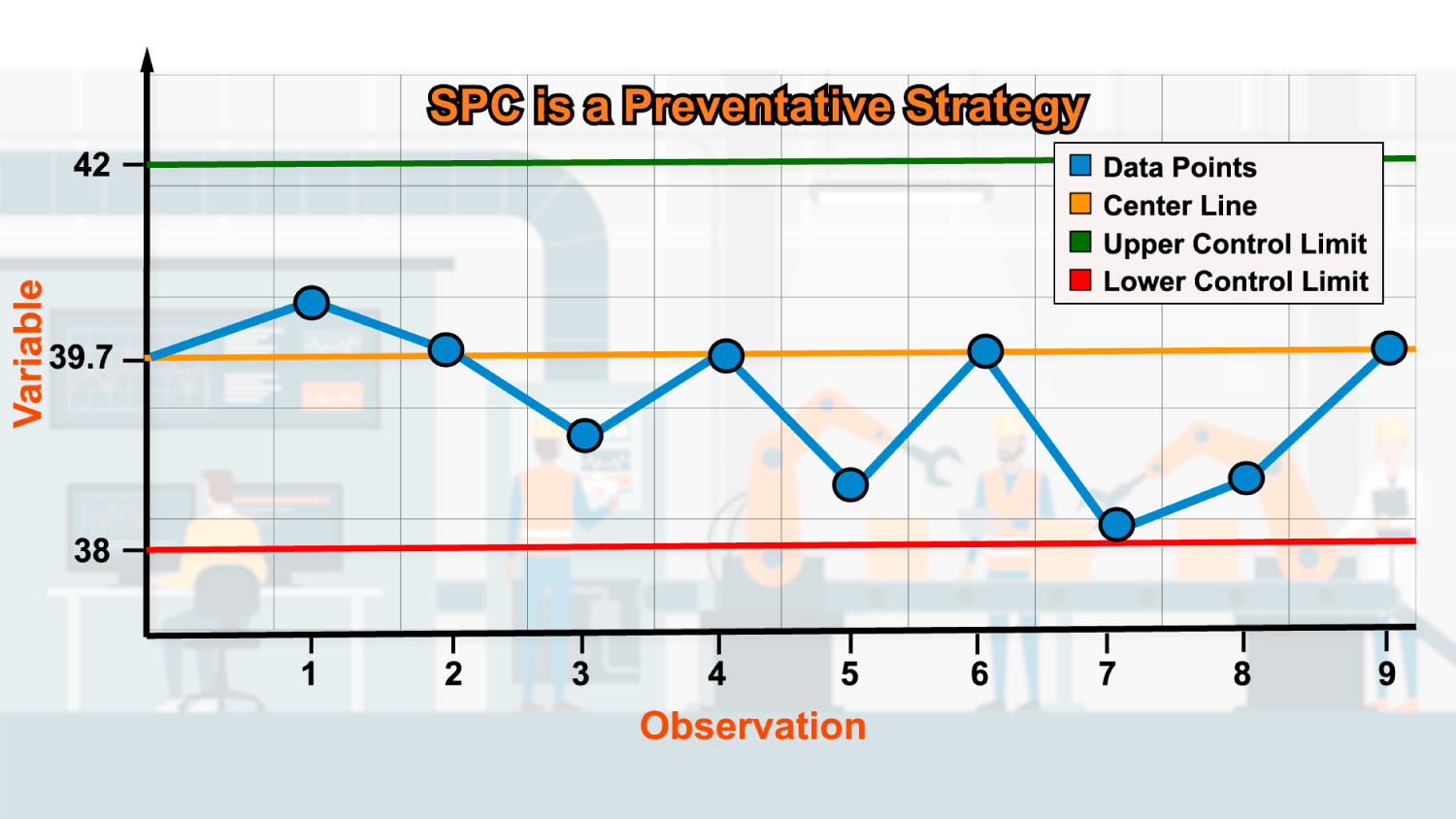

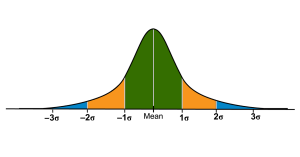

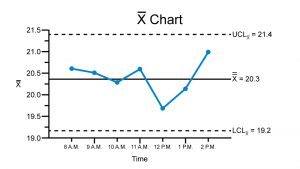

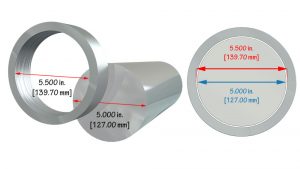

Variations are inherent to a process. An organization should effectively employ statistical process control (SPC) measures to reduce variations and eliminate nonconformance. This course offers a comprehensive overview of the basic statistical concepts, such as a process control system, process measures, control chart structure, and process capability. This course, presented in a visually engaging and highly interactive format, gauges your mind for a broader understanding of SPC.

Who will benefit from this statistical process control (SPC) course?

Marketing, Sales, Design, Engineering (Product and Process), Purchasing, Manufacturing, Quality, and Service functions at organizations that require an understanding of statistical process control; Any learner who is required to understand and use SPC

Course Classification

*THORS uses the Bloom’s Taxonomy Methodology for our course development.

Certificate Awarded for Statistical Process Control (SPC) Basics

*upon successful completion

Related Posts

Training Programs are Critical to Attracting and Retaining Talent

In today’s rapidly changing business landscape, organizations face a unique set of challenges in finding, hiring, and retaining top talent. The tight labor market has

Developing Soft Skills in the Tech Industry

Soft skills in the tech industry, where precision and expertise are paramount, might seem secondary. However, soft skills such as communication, teamwork, and problem-solving, play

Online Learning Levels the Playing Field for Students with Disabilities

Online learning has transformed the traditional education model and revolutionized education, offering students with disabilities the flexibility and convenience of learning from anywhere. With the