Course Description

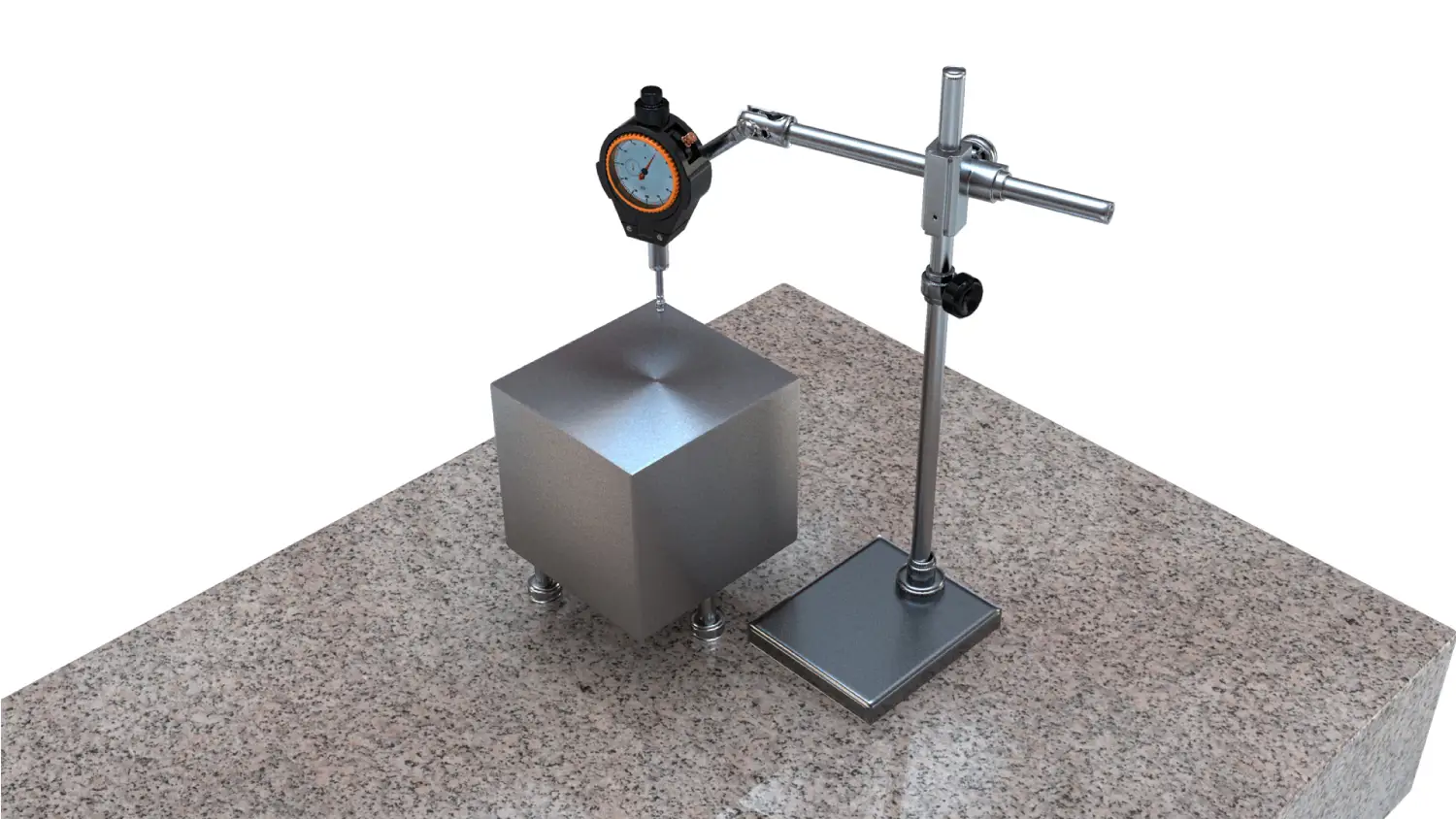

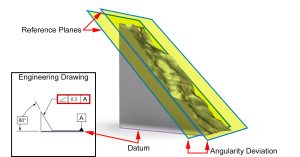

The THORS GD&T Measurement Basics course introduces the learner to the world of Geometric Dimensioning and Tolerancing (GD&T), including the importance of GD&T measurements, the definition of GD&T characteristics, and common shop floor measurement methods to measure each characteristic. Presented in THORS’ highly visual and interactive learning format, this course will help shop floor operators become familiar with the common measurement tools and procedures required for effective GD&T inspection of parts. |

Who will benefit from this GD&T measurement course?

Quality, manufacturing, engineering, design, test, purchasing, and sales functions at organizations that require a basic understanding of GD&T characteristics and their measurement tools.

Course Classification

*THORS uses the Bloom’s Taxonomy Methodology for our course development.

Certificate Awarded for GD&T Measurement Basics

*upon successful completion

Related Posts

Certificate Programs vs Completion Certificates

Certificate programs and completion certificates are both types of educational programs that can provide valuable training and skills to individuals in a variety of fields.

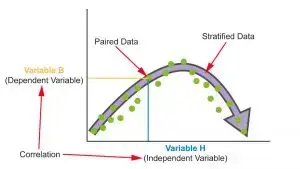

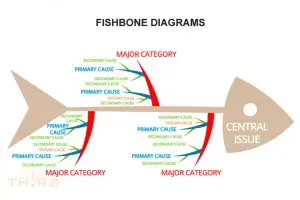

Fishbone diagrams help solve manufacturing problems

There can be many opinions as to what the root cause of a problem is, especially when there is a team tasked with solving an issue. A cause

5 Ways to Reduce Human Errors in Manufacturing

We cannot change the human condition, but in manufacturing we can certainly improve the way people work, where they work, and what systems they use.