Course Description

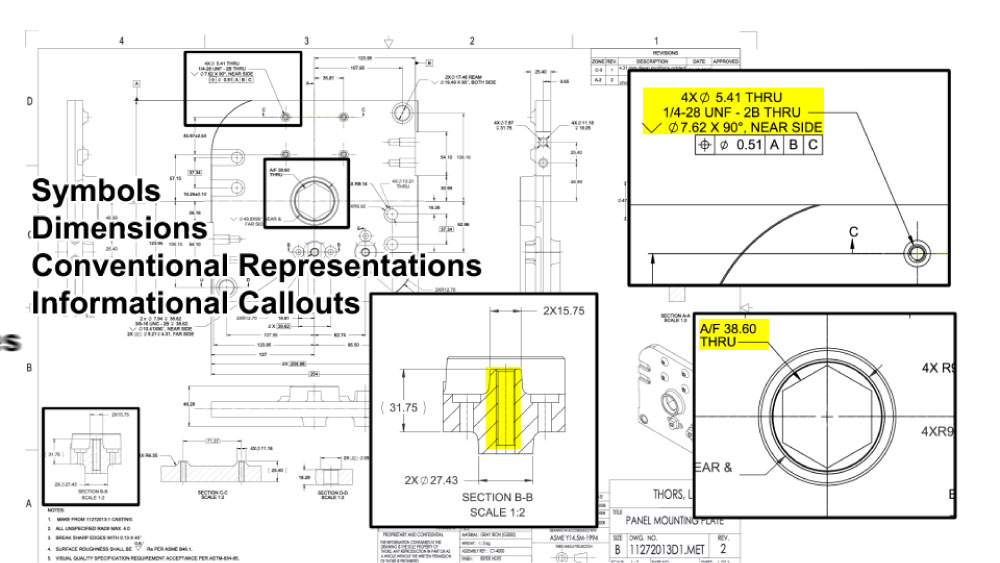

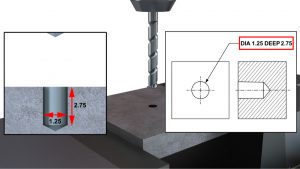

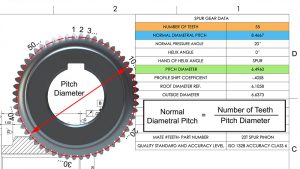

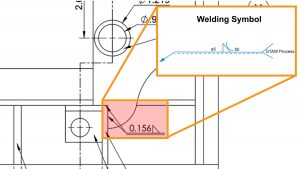

Engineering Drawings for Machining introduces the fundamental components and terminology used in reading engineering drawings used for machining processes. Presented in THORS’ highly visual and interactive learning format with many examples, this course assists employees in understanding and interpreting the information communicated on engineering drawings for machining.

Who will benefit from this Engineering Drawings for Machining course?

Engineering, manufacturing, quality, and purchasing personnel within any organization that produces parts using an engineering drawing.

Course Classification

*THORS uses the Bloom’s Taxonomy Methodology for our course development.

Certificate Awarded for Engineering Drawings for Machining

*upon successful completion

Related Posts

How THORS Courses Helped a Mechatronics Student in Germany

Sasshank is an international student attending University in Germany where he studies mechatronics engineering. He was born in Tamil Nadu, where he attended various schools

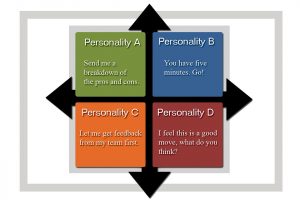

Knowing Customer’s Personality Style Adds Value

Maybe you think the value is obvious. If you can speak the same “language” as the person you are talking with, you can build trust

6 common misconceptions about training

Training is one of the most important tools for growing in one’s chosen career. Participating in continued learning and career advancement training programs will ensure