Course Description

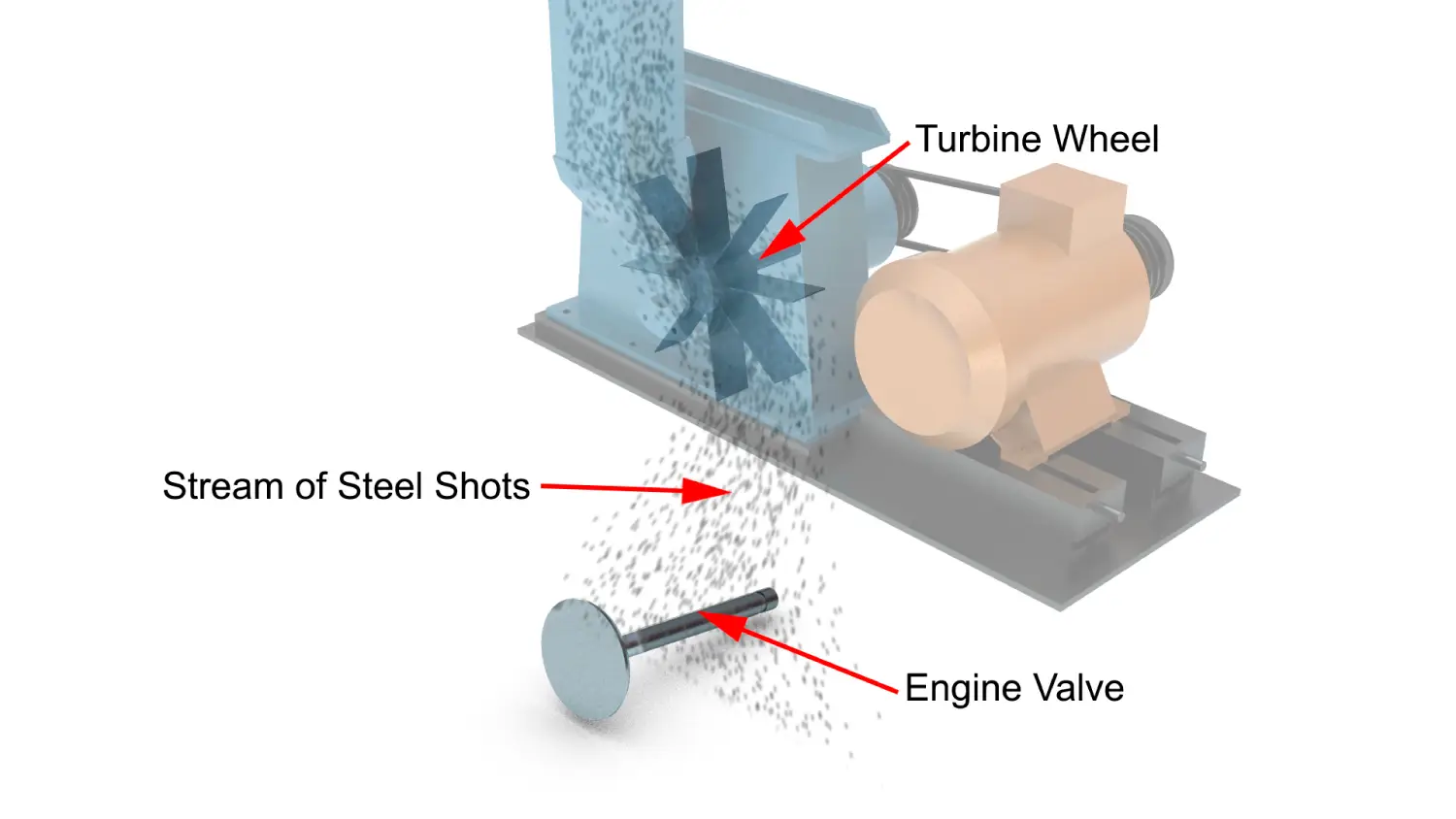

The THORS Engine Valve Manufacturing course begins with an in-depth understanding of the premachining processes involved in manufacturing an engine valve. This course also delves into machining processes, such as turning, centerless grinding, and cylindrical grinding, and other processes, such as special processes and final inspection, used in engine valve manufacturing. To enhance the learning experience, the course contains interactive quizzes that allow learners to test their knowledge and retention of the visually engaging content.

Who will benefit from this engine valve manufacturing course?

Sales, Purchasing, Manufacturing Engineering, Quality, and Design Engineering

Course Classification

*THORS uses the Bloom’s Taxonomy Methodology for our course development.

Certificate Awarded for Engine Valve Manufacturing

*upon successful completion

Related Posts

Why Digital Assessment Tools for Hiring are Essential

Hiring the right person for a technical position is crucial for the success of any organization. However, what happens when a new hire lacks the

Is Your Issue a Skills Gap or a Knowledge Gap?

You may have received a call to action to address the skills gap, which might feel making a bridge across the Grand Canyon with a

7 of The Latest Techniques in Electrostatic Discharge (ESD) Prevention

In the ever-evolving landscape of electronics, the threat of Electrostatic Discharge (ESD) looms large. As technology advances, devices become smaller, more sensitive, and consequently, more