Course Description

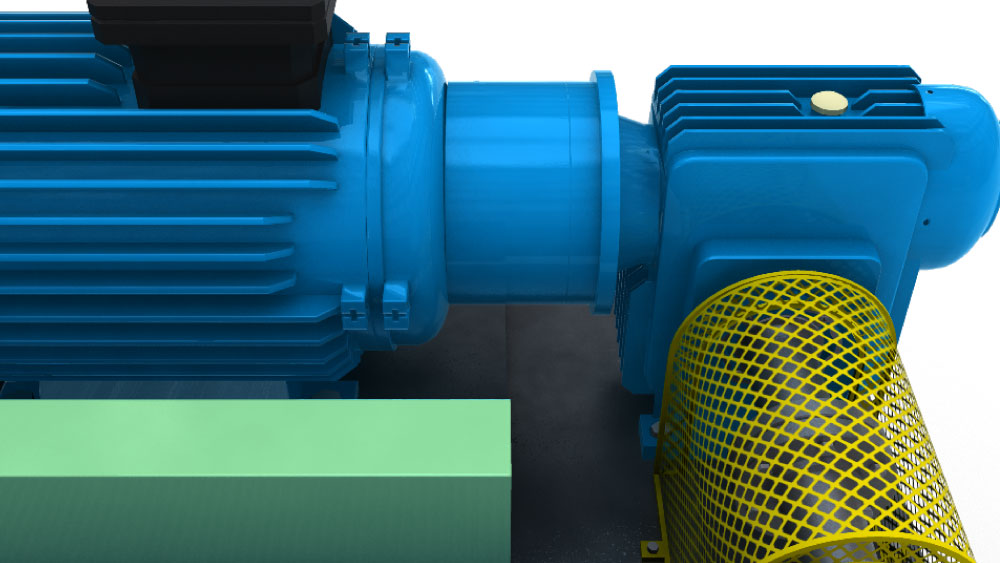

Gearbox Basics introduces the learner to key principles of gearbox operation, as well as typical classification, components, and specification of gearboxes. Featuring a variety of detailed 3D gearboxes used in light-, medium-, and heavy-duty industrial applications, the course supplies fundamental knowledge relevant for gearbox purchasers and suppliers alike. Learners in quality, manufacturing, or engineering roles in the industry will also find value in this course.

Who will benefit from this Gearboxes course?

Quality, manufacturing, engineering, purchasing, and sales functions at organizations that require an understanding of gearbox components, classification, and specification.

Course Classification

*THORS uses the Bloom’s Taxonomy Methodology for our course development.

Certificate Awarded for Gearbox Basics

*upon successful completion

Related Posts

Benefits of eLearning in Manufacturing

In the world of manufacturing, training is essential. Every employee needs to understand how to use equipment, follow procedures, and maintain quality standards. With the advent

Training Programs are Critical to Attracting and Retaining Talent

In today’s rapidly changing business landscape, organizations face a unique set of challenges in finding, hiring, and retaining top talent. The tight labor market has

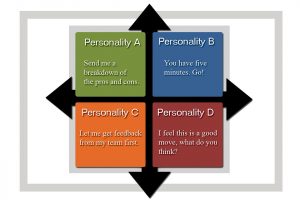

Knowing Customer’s Personality Style Adds Value

Maybe you think the value is obvious. If you can speak the same “language” as the person you are talking with, you can build trust