Course Description

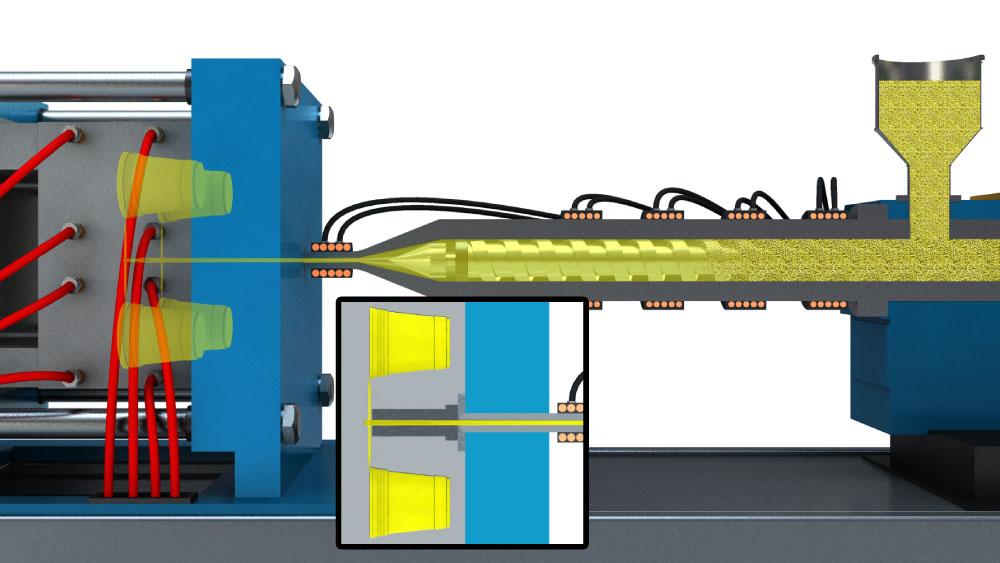

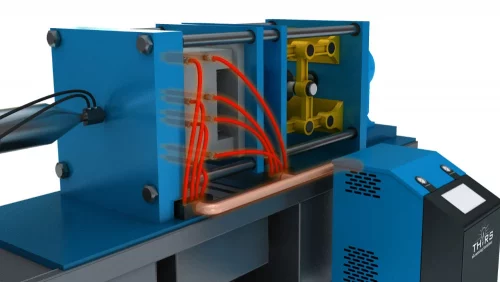

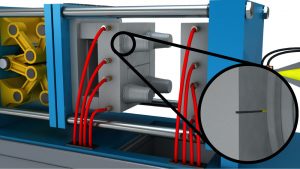

Polymers: Injection Molding Process is an informative, intermediate-level course on the injection molding process. In this course, learners are introduced to the stages of the injection molding process, including plastification, injection, and cure and ejection; the methods to optimize each step in the process; as well as the steps required to establish the process. Learners in quality, manufacturing, sales or related, and research and development in the industry will find value in this course.

Who will benefit from this Injection Molding Process course?

R&D new hires, manufacturing process engineers, sales reps – technical sales, account managers, product developers, tech service, product managers, quality managers.

Course Classification

*THORS uses the Bloom’s Taxonomy Methodology for our course development.

Certificate Awarded for Polymers: Injection Molding Process

*upon successful completion

Related Posts

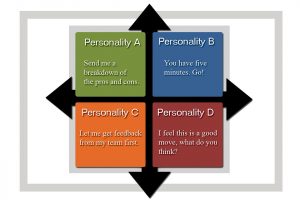

Knowing Customer’s Personality Style Adds Value

Maybe you think the value is obvious. If you can speak the same “language” as the person you are talking with, you can build trust

How to Make Your Home Learning Environment Top Notch!

Since COVID shutdowns and the work from home revolution, there’s been a lot of discussion about making a home space conducive to working. But what

Is your issue a skills gap or a knowledge gap?

You may have received a call to action to address the skills gap, which might feel making a bridge across the Grand Canyon with a