Course Description

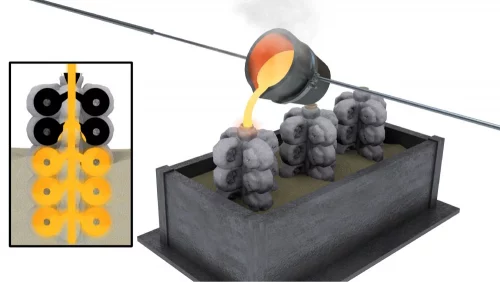

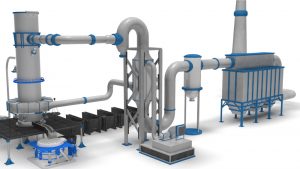

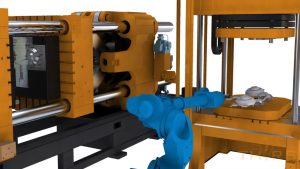

Investment Casting Basics introduces learners to the terminology, equipment, and processing steps associated with metal investment casting. Using animated demonstrations and other visual aids to break down complex concepts, the course aims to improve process knowledge for employees in investment casting foundries and in peripheral professions.

Who will benefit from this Investment Casting course?

Companies, individuals, or educational institutions who wish to more clearly understand the terminology, equipment, and processing steps associated with investment casting.

Course Classification

*THORS uses the Bloom’s Taxonomy Methodology for our course development.

Certificate Awarded for Investment Casting Basics

*upon successful completion

Related Posts

Cross-Cultural Training Benefits

Understanding Cross-Cultural Training In today’s interconnected world, businesses are expanding beyond borders. To thrive globally, organizations must equip their employees with cross-cultural skills. Cross-cultural training

Exploring the Differences Between Casting and Forging

Differences Between Casting and Forging In the world of manufacturing, few processes can match the intricate artistry and skilled precision of casting and forging, which

The Essential Skills of Modern Purchasing Professionals

In my professional career that spans more than three decades, I have had the privilege of working closely with purchasing. I can attest to the