Course Description

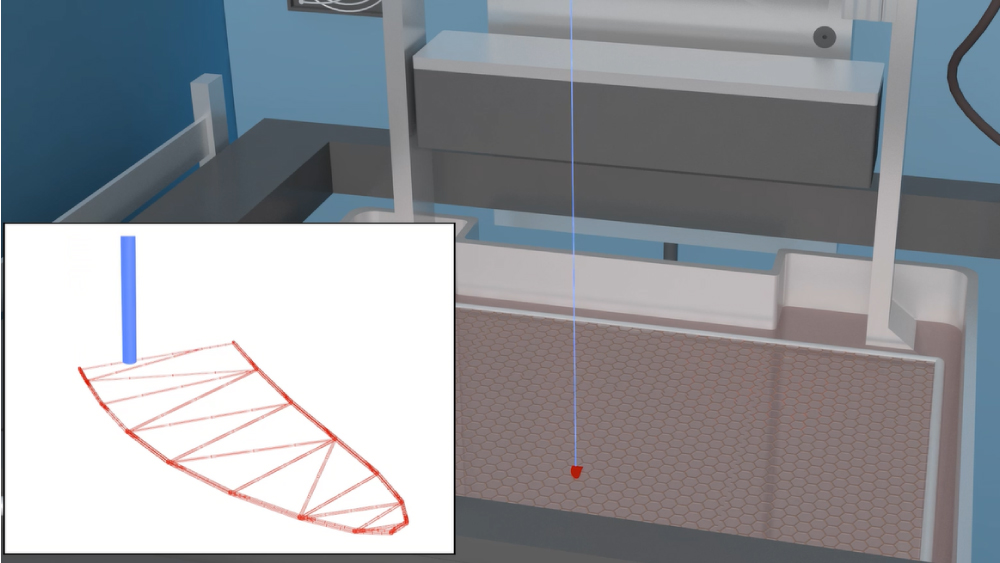

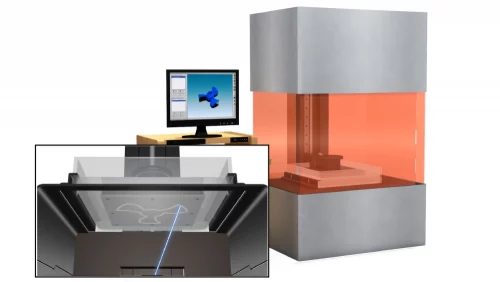

The Additive Manufacturing: Stereolithography course is an informative, entry-level overview of the stereolithography additive manufacturing process. In this course, learners are presented with the basics of stereolithography, its process, and the necessary process considerations. Learners in the quality and manufacturing fields will find value in this course.

Who will benefit from this Stereolithography Additive Manufacturing course?

OEMs that manufacture, design, or procure components from Additive Manufacturing or 3D printing companies; Any manufacturer looking to introduce Additive Manufacturing concepts; Additive Manufacturing service bureaus; Educational institutions; Students and aspiring industry professionals.

Course Classification

*THORS uses the Bloom’s Taxonomy Methodology for our course development.

Certificate Awarded for Additive Manufacturing: Stereolithography

*upon successful completion

Related Posts

Cross-Cultural Training Benefits

Understanding Cross-Cultural Training In today’s interconnected world, businesses are expanding beyond borders. To thrive globally, organizations must equip their employees with cross-cultural skills. Cross-cultural training

The Role of eLearning in Compliance Training

In today’s fast-changing business environment, effective compliance training is more crucial than ever. eLearning in compliance training has emerged as a powerful tool for ensuring

Upskilling in the Manufacturing Industry with THORS

In today’s rapidly evolving manufacturing industry, staying up to date with the latest technologies and processes is crucial to remaining competitive. Upskilling in the manufacturing industry