In heat treatment, racking and stacking strategies are important to ensure the desired hardness, toughness, and dimensional stability required for demanding applications. Whether the part is a small fastener or a large structural component, heat treatment is a cornerstone of modern manufacturing. While the science of heat treatment often focuses on temperatures, time cycles, and atmospheres, an equally critical but sometimes overlooked aspect is how parts are racked and stacked inside the furnace.

The way parts are arranged directly impacts heat transfer, airflow, temperature uniformity, distortion control, and surface quality. Improper racking can lead to uneven hardness, warpage, oxidation, or even scrap. In this blog, we’ll explore the top 5 racking and stacking strategies followed during heat treatment and why they matter.

1. Maintain Spacing and Airflow Balance

One of the golden rules of furnace loading is ensuring that each part has enough free space around it for heat to circulate evenly. If parts are stacked too close, hot gases cannot flow freely between surfaces, leading to temperature gradients and inconsistent treatment. At the same time, stacking too sparsely wastes furnace capacity.

Heat transfer in furnaces is driven by conduction, convection, and radiation. Without adequate spacing, some areas remain cooler, resulting in under-hardened or under-treated zones. It’s necessary to maintain a minimum of one to two inches of clearance between parts and arrange in grids or cross-stacks that allow airflow while optimizing load efficiency.

2. Use Dedicated Fixtures and Jigs

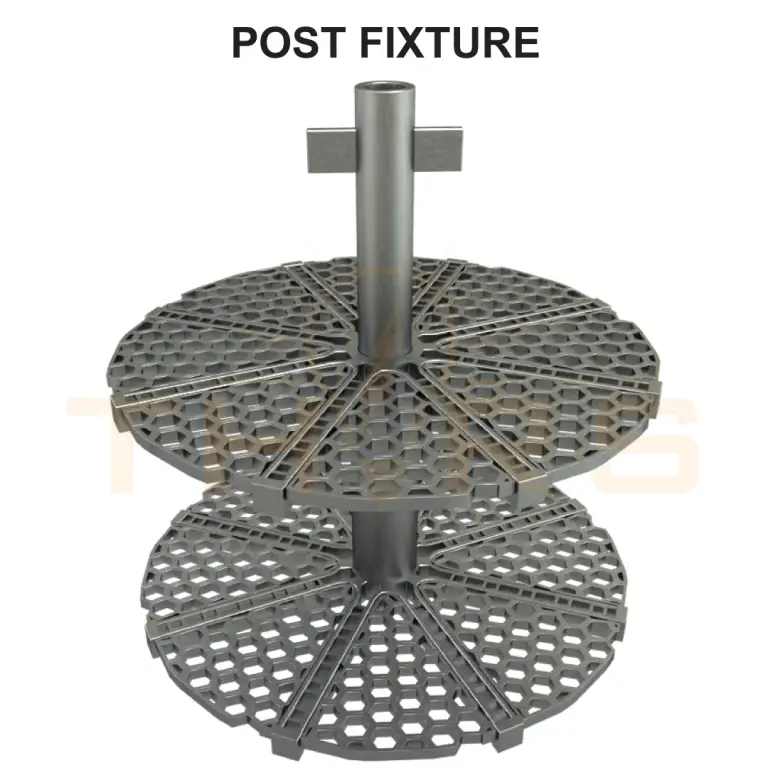

Dedicated racking fixtures are one of the best investments for repeatable and distortion-free heat treatment. Fixtures are designed to hold parts securely, maintain orientation, and allow maximum heat flow. Heat-resistant alloys, such as Inconel or stainless steel, are used since they can withstand repeated thermal cycles. Fixtures often incorporate open frames, slotted supports, or mesh designs to reduce shadowing and allow uniform gas flow. For complex parts, jigs are designed to support critical areas, preventing sagging or warpage.

3. Orient Parts for Both Heating and Quenching

Orientation plays a role at two critical stages of heat treatment: heating and quenching. If ignored, distortion, cracking, and uneven properties can result.

- During heating: Thin shafts and rods should be loaded vertically to avoid sagging; flat plates should be stacked with support points to prevent bending. Asymmetric parts should be oriented to distribute thermal expansion evenly.

- During quenching: Orientation controls coolant flow. Plates are best quenched vertically to avoid uneven cooling; cylindrical parts should be placed to allow full fluid circulation around them; complex geometries should be positioned to avoid trapping vapor bubbles.

4. Prevent Contact Marks and Surface Defects

Direct metal-to-metal contact during heat treatment can cause defects such as soft spots, decarburization marks, or imprints on the finished surface. Proper racking strategies reduce or eliminate these issues.

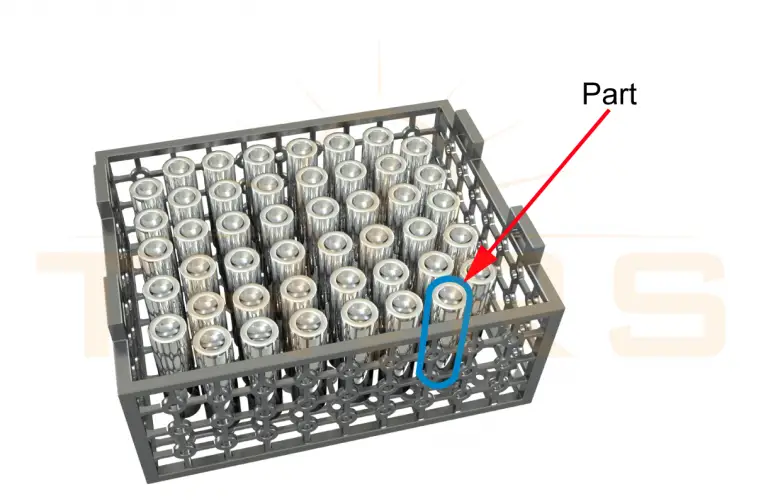

- Separators and spacers: Ceramic spacers or heat-resistant alloy pins prevent direct contact.

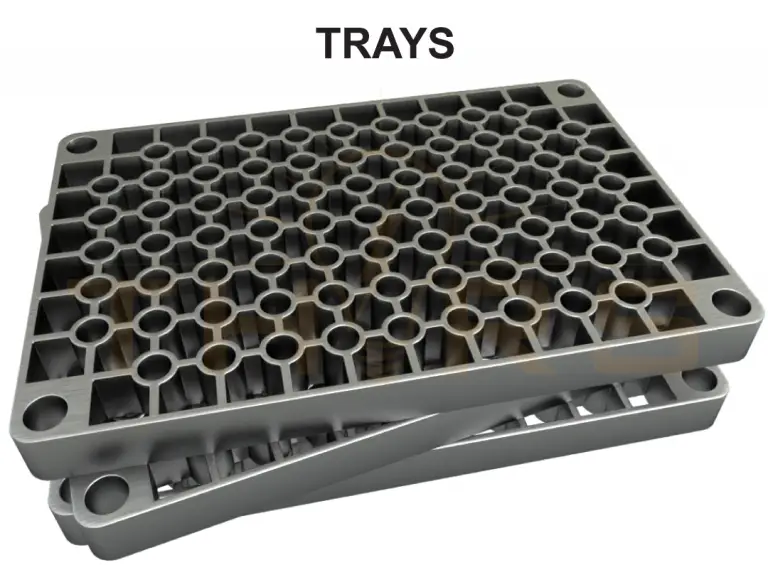

- Baskets and trays: Small components can be placed in baskets and trays that minimize surface contact.

- Non-reactive coatings: Some racks are coated with ceramic or protective coatings to prevent sticking.

5. Ensure Ease of Handling and Safety

The goal of heat treatment isn’t just to improve metallurgical quality—it’s also about safe and efficient handling. Racking and stacking strategies should minimize risks for workers and ensure parts can be loaded or unloaded without damage.

- Accessibility: Racks should allow parts to be handled with tongs, cranes, or manipulators without squeezing or scratching surfaces.

- Stability: Stacks should be stable to prevent tipping during loading, transport, or quenching.

- Ergonomics: For small parts, baskets and trays should be sized for safe lifting and reduced manual strain.

Heat treatment is as much about how parts are loaded as it is about temperatures and cycles. The right racking and stacking strategies ensure:

- Uniform hardness across all parts

- Reduced distortion and scrap

- Better surface quality and reduced post-processing

- Higher efficiency and repeatability

- Safer, more ergonomic shop-floor operations

In recent days, advanced materials such as carbon-carbon composites are used in making racks and are used instead of metal racks for increased energy efficiency and productivity.

The THORS course, Heat Treating Racking and Stacking offers in-depth exploration into understanding the various racking and stacking techniques for diverse heat treatment processes and equipment.