In the evolving world of industrial automation, both traditional and modern technologies coexist to drive control systems. The foundational devices of industrial automation systems are electromechanical relays in traditional automation systems and Programmable Logic Controllers (PLCs) in modern automation systems. Electromechanical relays are long-trusted switching components. On the other hand, PLCs are microprocessor-based control devices that bring flexibility, scalability, and advanced logic capabilities to modern automation systems. Although PLCs and relays each play a unique role, they share the same goal of automating and streamlining industrial operations. From managing assembly lines to controlling complex machinery, PLCs are built to perform reliably in demanding environments. This blog explores what PLCs are, how they differ from electromechanical relays, and why they are central to the future of industrial automation.

The Role of Electromechanical Relays

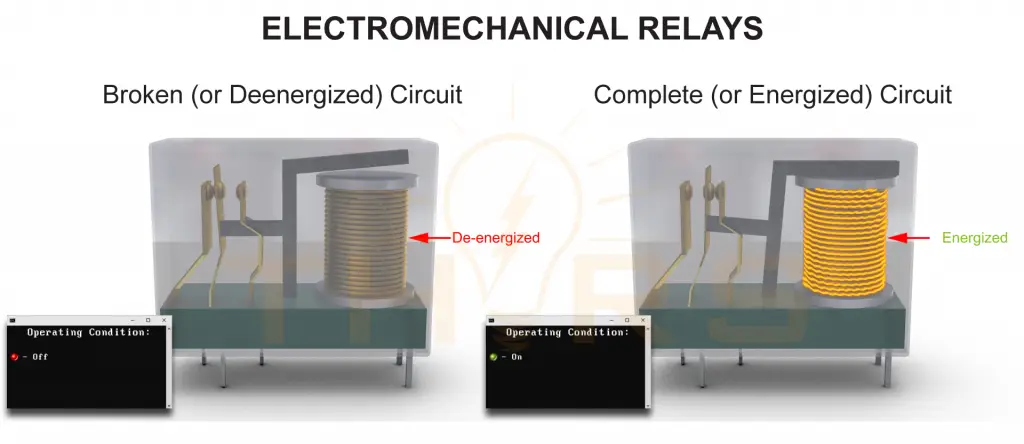

Electromechanical relays have been around for decades. At their core, they are mechanical switches activated by electrical signals. When a small control current flows through the coil of a relay, it generates a magnetic field that moves a contact, completing or breaking a circuit.

This simple mechanism allows a relay to control larger loads, such as motors, lights, or heaters, with a relatively small input signal.

Relays are commonly found in:

- Basic motor starters

- Alarm systems

- Lighting panels

- Equipment with minimal automation requirements

Despite being mechanical, they are valued for their simplicity, low cost, and direct control capability. However, as systems become more complex, relays tend to show limitations, such as increased wiring complexity, limited logic functions, slower switching speeds, and a lack of diagnostics or memory capabilities.

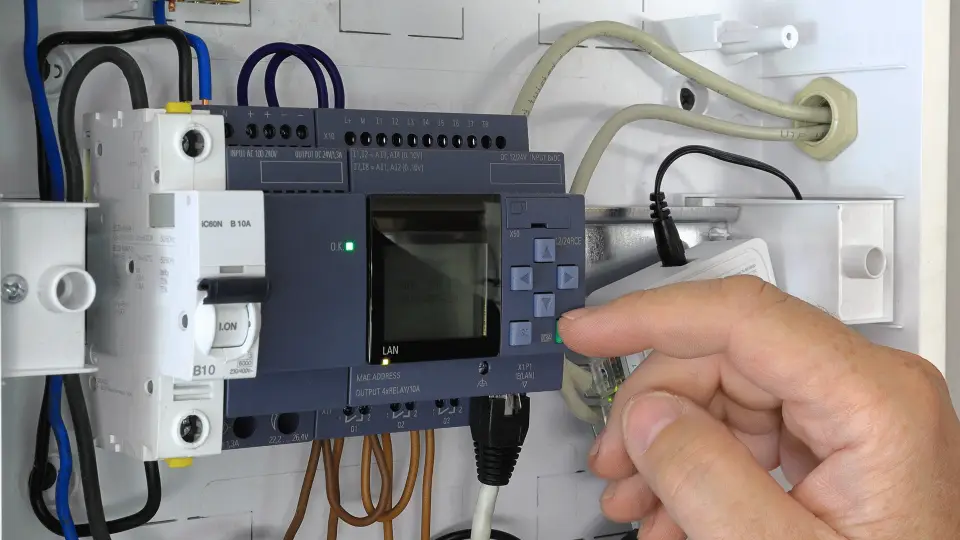

The Emergence of PLCs

As industries demanded smarter, more flexible control systems, PLCs emerged as a revolutionary alternative, then went a step further: integrating traditional logic functions with features such as real-time monitoring, diagnostics, data exchange, and network connectivity.

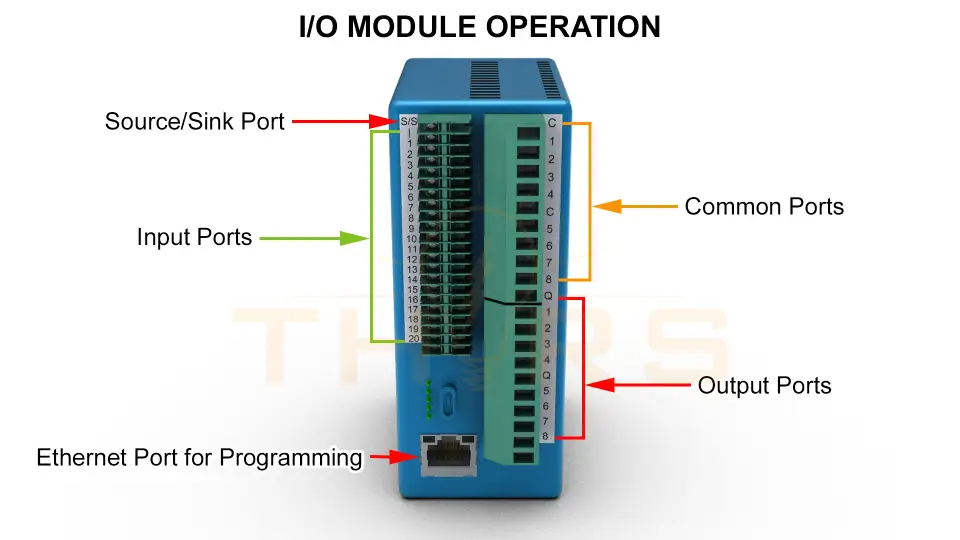

PLCs in modern automation are compact industrial computers that handle tasks once spread across multiple relays, timers, and counters. More importantly, they do this with minimal physical wiring and far greater flexibility.

PLCs are often seen in:

- Conveyor systems

- Automatic packing lines

- Water treatment plants

- Energy management systems

- Building automation

Their ability to adapt to changing requirements makes them ideal for scalable and future-ready automation solutions.

Advantages of PLCs

1. Wiring Made Simple

One of the biggest advantages of moving from relay-based systems to PLCs is the control panel design itself. Traditional relay systems often result in bulky panels filled with wires. Each function, such as start or stop, delay, or interlock, requires its own set of components.

PLCs, on the other hand, streamline the entire setup. A single unit can control dozens of devices with only minimal wiring, drastically reducing installation time, space, and points of failure.

2. Maintenance and Monitoring

As the relays are mechanical components, they are more prone to wear out over time. Contacts may become pitted or stuck, leading to system failures. Diagnosis usually involves manually checking each connection, which is time-consuming and inefficient.

PLCs simplify this process with built-in status indicators, error logs, and even remote diagnostics. Instead of hunting through wires, technicians can view system status on a screen or remotely through connected systems. This leads to faster troubleshooting, less downtime, and more efficient maintenance.

3. Application Flexibility

While relays are best suited for fixed, repetitive tasks, PLCs shine in environments that demand adaptability. Changes in workflow, equipment upgrades, or process modifications are easy to manage with PLCs without any major hardware changes.

A new sensor or motor can be added, signals rerouted, and logic adjusted, all within the same device. This kind of flexibility makes PLCs invaluable in today’s rapidly changing industrial environments.

4. Benefits of PLCs in Industrial Automation

• Improved Scalability

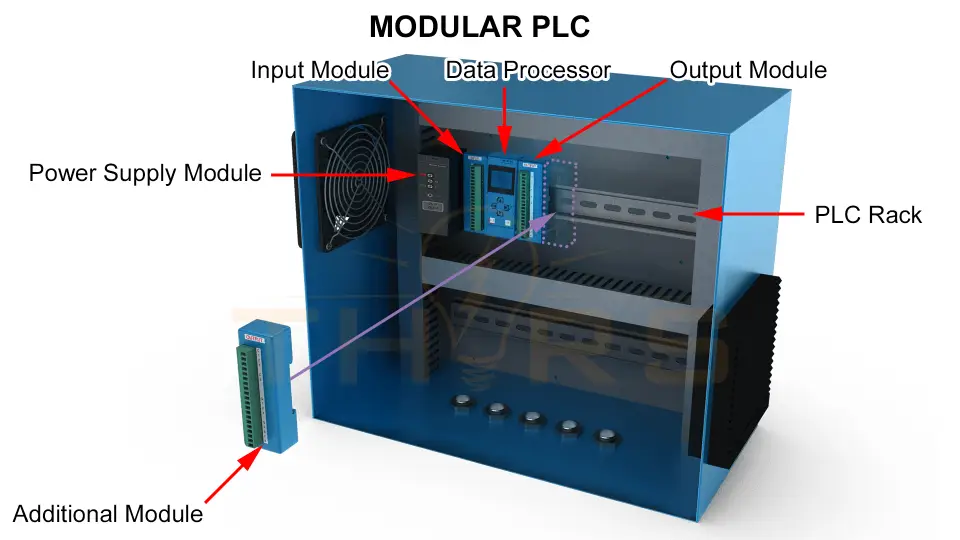

PLCs are modular and can be scaled easily to support larger systems without complete redesign. Their support for open standards also ensures compatibility across devices from different vendors.

• Enhanced Data Utilization

With real-time access to operational data, companies can optimize production, reduce downtime, and improve decision-making. PLCs act as data hubs, converting raw signals into actionable insights.

• Lower Operational Costs

By enabling remote diagnostics, predictive maintenance, and intelligent fault detection, PLCs help reduce both planned and unplanned maintenance costs.

The Coexistence in Modern Industry

It’s important to note that PLCs and electromechanical relays are not always in competition. In fact, they often work together. PLCs may send output signals to a relay, which in turn controls a high power device. Relays still play a role in isolating loads, handling surge currents, or providing manual overrides in critical systems. Many modern control systems are a blend of both technologies, where it matters, and simple where it counts.

The Future of PLCs

PLCs are bridging the gap between operational technology (OT) and information technology (IT). As Artificial Intelligence (AI) and Internet of Things (IoT) continue to evolve, PLCs will not only control machines but also understand processes, optimize workflows, and enable autonomous decision-making.

Future PLC systems will likely be:

- Software-defined, reducing reliance on specific hardware

- AI-enhanced, capable of pattern recognition and self-correction

- Easily configurable via cloud platforms or mobile apps

Conclusion

Industrial automation is not about choosing between old and new, but instead about using the right tool for the application. Electromechanical relays offer reliability and simplicity for basic control needs, while PLCs provide the intelligence, efficiency, and adaptability required by modern systems. PLCs in modern automation represent a significant leap forward in automation technology. With their ability to process data, connect with enterprise systems, and support intelligent control, they’re rapidly becoming the most important devices in modern industrial environments. Understanding both allows engineers and technicians to build robust, scalable, and efficient control systems that stand the test of time.

Want to learn more? Check out the THORS Academy course, Programmable Logic Controller (PLC) Basics.