Role of Quality Control in Manufacturing

Quality control is the often overlooked yet highly crucial aspect manufacturing. It serves to ensure products meet the necessary requisites of the effective functionality and durability. In the wide world of manufacturing, the impact of overlooking quality can be highly detrimental. While the obvious consequence is the dissatisfaction of customers, leading to potential profit loss, the true significance of quality control far deeper than this superficial consequence. Let’s delve into the layers of why quality control plays a pivotal role in the manufacturing industry.

Cost Reduction: One might perceive stringent quality control measures as contributing to increased expenses in manufacturing. However, the reality is quite the opposite. Efficient quality control measures can significantly reduce production costs. Timely identification and rectification of errors and defects mitigate the need for extensive rework at later stages, thereby minimizing operational expenses and reducing the waste of raw materials. This cost reduction not only enhances the bottom line but also fosters a culture of efficiency within the manufacturing process.

Moreover, investing in efficient quality control proves to be a strategic move with a notable Return On Investment (ROI). According to the MIT Sloan Management Review, product failures result in lower service costs, ultimately enhancing a firm’s profitability. In essence, quality control becomes not just a cost-saving measure but also a pathway to increased returns and sustained success of a brand.

Compliance and Ensuring Safety: Quality control goes hand-in-hand with compliance and safety. It ensures adherence to specific local, international, and national regulations, preventing safety hazards or ethical violations that may arise from faulty products. By incorporating rigorous checks, quality control acts as a safeguard against potential legal issues and reinforces the ethical standing of a manufacturing entity.

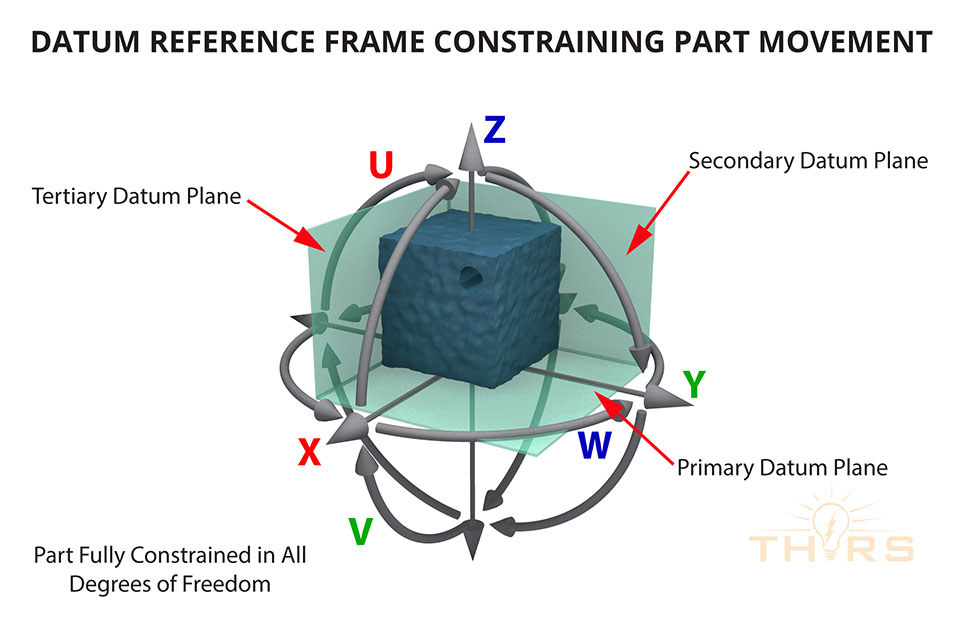

Minimize Variations: Consistency is integral in manufacturing, and quality control measures strive to establish uniformity across all products. This consistency not only meets customer expectations but also aids in building a brand’s identity based on reliability and trust.

Building Trust and Reputation: Building trust and reputation are paramount in the business landscape, and quality control is a key player in achieving this. An efficient quality control system instills confidence in customers, solidifying the reputation of a brand or firm. Consistently delivering products and services not only fosters customer loyalty but also attracts new business opportunities, leading to increased sales and market share.

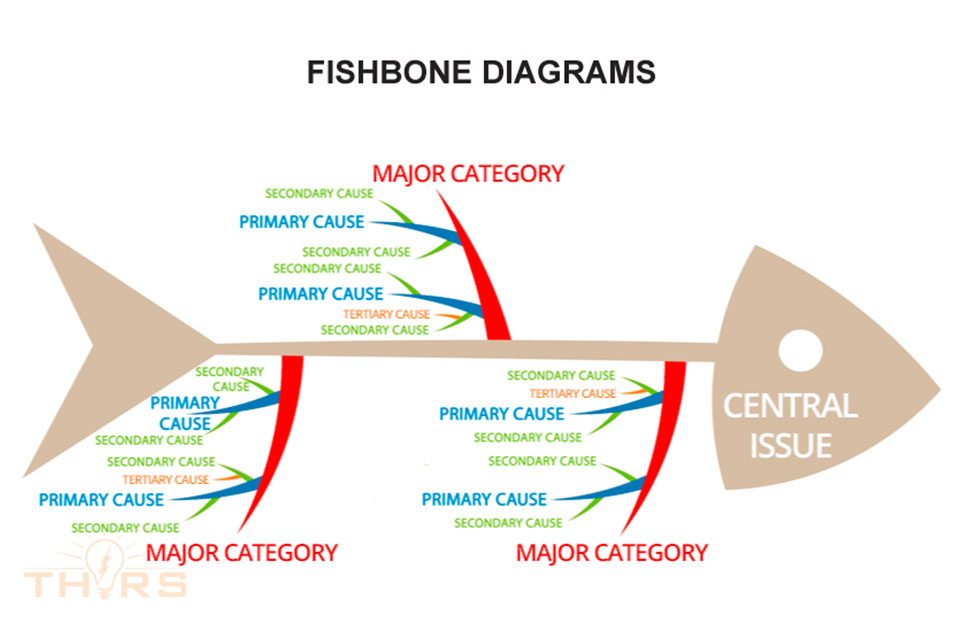

Continuous Improvement: Quality control just about maintaining current standards; it is also about evolving them. The process involves identifying and rectifying defects or inadequacies in current practices. This continual improvement is achieved through integrating feedback loops, analyzing data, and adapting standards to enhance quality continuously. By embracing this dynamic approach, manufacturing entities can stay ahead of the curve and remain competitive in an ever-evolving market.

In conclusion, the role of quality control in manufacturing extends far beyond the surface level of customer satisfaction. It is a multifaceted process that contributes to cost reduction, ensures compliance and safety, minimizes variations, builds trust and reputation, and enhances quality standards. Investing in a robust quality control system is not just a business necessity, it is a strategic imperative for long-term success and sustainability in the manufacturing industry.