This month, let’s learn all about some effective ways of reducing bond usage in green sand systems.

Firstly, bond is added to green sand systems to:

1.Replace burnt or inactivated bentonite due to the heat of the metal poured surrounding the casting in the mold (for ferrous castings, 25 to 35 pounds of bentonite/per ton of metal).

2.Replace material lost to dust collection at various stages in the processing and handling of the sand mix (varies from 20 pounds to over 40 pounds of bentonite per ton depending on process).

3.Provide bonding material for the new sand grains added to the system via new sand addition and core sand dilution (varies from 10 pounds to over 40 pounds of bentonite per ton of metal).

Overall clay consumption could vary widely from a low of 70 pounds to over 150 pounds per ton of iron poured depending on variables discussed below.

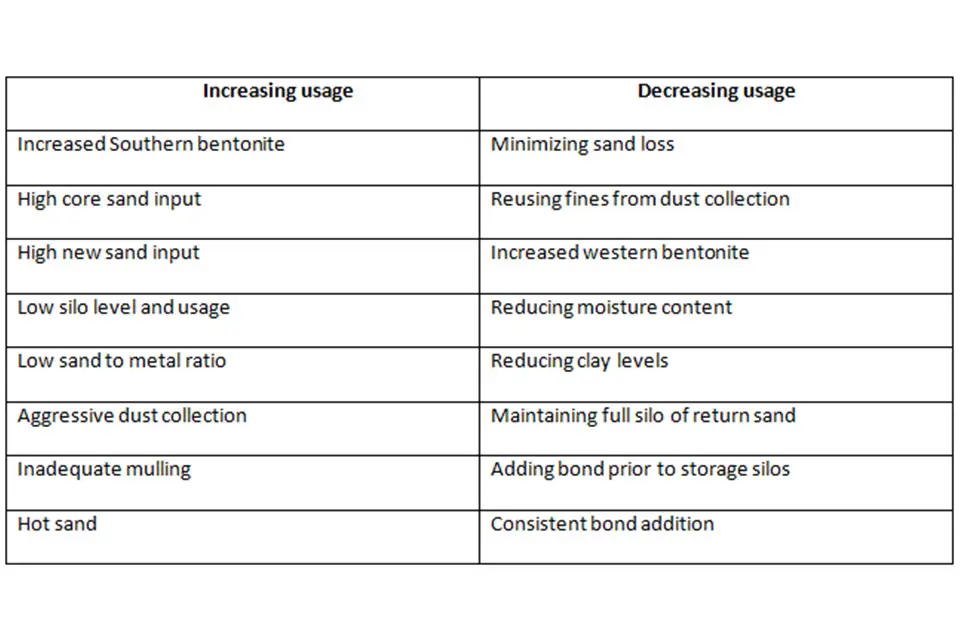

It is essential to understand various factors that affect bond usage so that addition rates can be minimized. The amount of bond used depends on many factors. The factors can be grouped under three main areas:

• Materials – which affects bond inactivated by metal

• System Design – which affects material lost

• Operation – which affects the level of clay required

1) Materials:

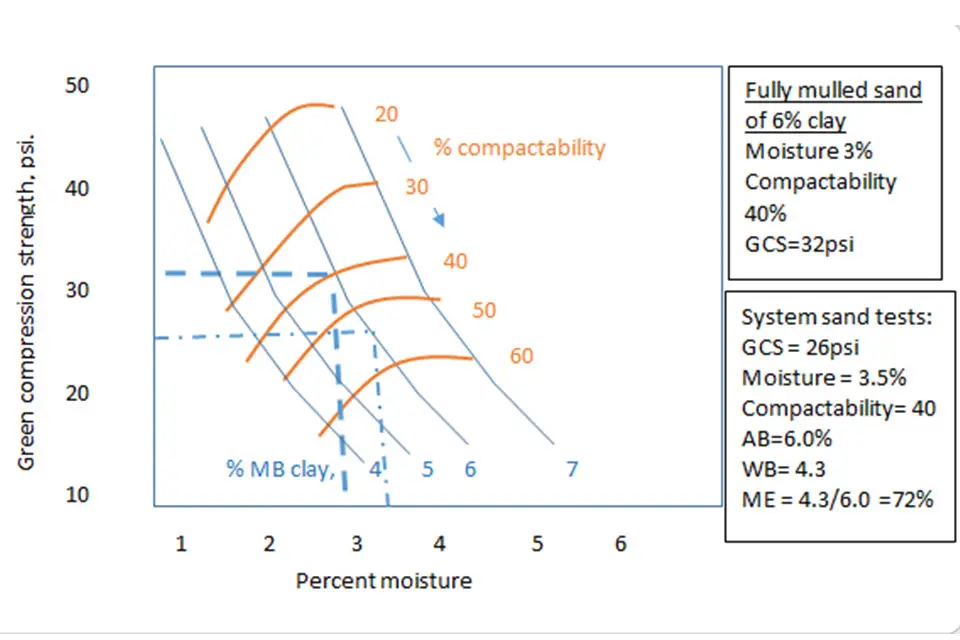

Bond mix may have many ingredients, the most important being clay. Clay is the key material that gives the bonding and refractory properties to the molding sand. The amount of clay in the system necessary to produce a good mold and castings varies by the type of clay used, as well as the metal poured into the molds. Western bentonite (Sodium ion) is durable and the proportion of clay made inert by heating the sand is lower than southern (Calcium ion) bentonite. Other materials added to the bond mix such as sea coal, cereals, and cellulose may interfere with strength development. Hence, to use minimum amount of clay per ton of metal poured, western bentonite is usually preferred. Minimizing other materials added to the bond mix also helps in reducing bond usage.

The type of metal poured affects bond consumption. The higher the temperature of metal poured, the higher the amount of bond inactivated, which results in higher amounts to be replaced.

2) System Design:

Sand cooling – return sand above 130°F is too dry and the loss of bonding materials increases during handling.

Storage silo capacity and utilization – small storage silos and low levels of sand in the silos reduces clay activation time and increases the need for clay addition.

Method and location of bond addition – if all of the bond is added at the muller, there is not much mulling time to develop the bond and higher amounts of bond addition will be required. By adding most of the bond prior to the return sand silos, an extended time period is provided for the clay to absorb water and to develop strength more quickly. This will reduce the clay level necessary to maintain adequate green strength.

Core sand and lump reduction and screening – increased core sand dilution into the return sand will require higher amounts to bond the new grains.

Dust collection – aggressive dust collection, especially when the sand is dry, will remove active bond materials along with inert fines and dust. This loss needs to be made up in increased additions.

Recycling of material collected at various points – since there is a considerable amount of usable material in the dust collection bins, adding controlled amounts of these materials back into the system will help in reducing bond usage. Black water systems uses this principle to recycle usable material back into the system. The clay in the black water system is already activated and requires less mulling.

Shakeout system – inadequate shakeout equipment will allow more sand to be lost with the casting and sprue, requiring increased new sand addition, increasing the bond addition.

3) Operation:

Sand to metal ratio – a low sand-to-metal ratio will require the clay level to be high, which means the addition rate will be high. This depends on the job mix and molding system. A cope and drag system will have higher sand to metal ratios compared to vertically parted molding.

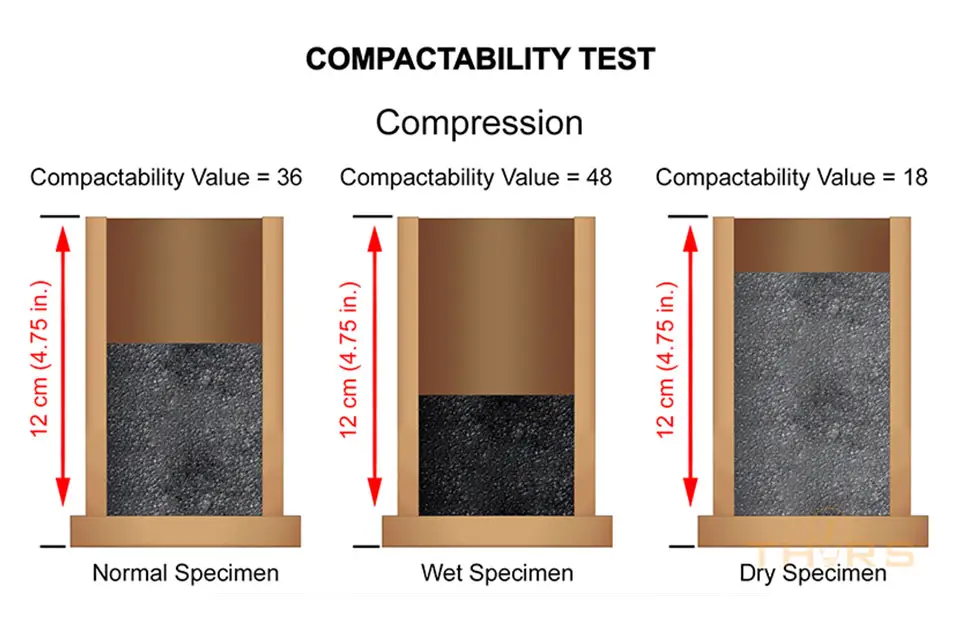

Compactability – strength development is controlled by compactability at the muller. If the set point is high, the green compression strength developed will be lower, and the tendency is to increase the clay addition Sand carryout – when more sand is carried out with castings due to deep pockets, hard molds, and high dry and hot strength sands, more new material needs to be added to maintain full return sand silos. This extra new material will require more bond addition.

Sand carryout – when more sand is carried out with castings due to deep pockets, hard molds, and high dry and hot strength sands, more new material needs to be added to maintain full return sand silos. This extra new material will require more bond addition.

Silo maintenance – when sand builds up on the walls, the capacity is reduced considerably. Low utilization of silo capacity will lead to low resident time and low levels of activation of clay.

Bond addition method – if bond is added to dry sand while mixing and dust collection is in operation, more material will be lost. It is necessary to audit equipment for calibration and maintaining for proper operation to minimize bond usage.

Was this content useful to you? Check out our full list of green sand courses.