Course Description

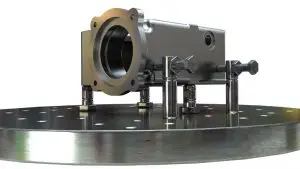

Machining: Surface Process Fundamentals is designed to provide learners with terminology, images, and fundamental concepts as they pertain to metal machining processes that create a surface feature on a part. Presented in THORS’ highly visual and interactive learning format, this course will help employees in machining industries become familiar with the important equipment and terminology associated with their profession.

Who will benefit from this Machining Surface Processes course?

Companies, individuals, or educational institutions that require an understanding of the components and terminology associated with surface processes in machining.

Course Classification

*THORS uses the Bloom’s Taxonomy Methodology for our course development.

Certificate Awarded for Machining: Surface Process Fundamentals

*upon successful completion

Related Posts

Why Digital Assessment Tools for Hiring are Essential

Hiring the right person for a technical position is crucial for the success of any organization. However, what happens when a new hire lacks the

5 signs you should invest in effective workforce training

In today’s constantly changing marketplace, the importance of workforce training has never been greater. Workforce training has the ability to not only increase workforce efficiency

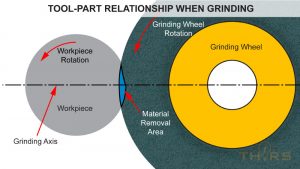

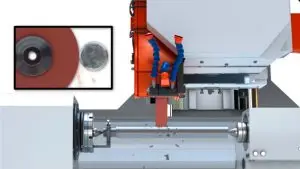

Cylindrical Grinding in Manufacturing is Fueled by Five Factors

In modern manufacturing, cylindrical grinding plays a crucial role, emerging as a key process. Let’s explore the intricate world of cylindrical grinding; its diverse applications,