Course Description

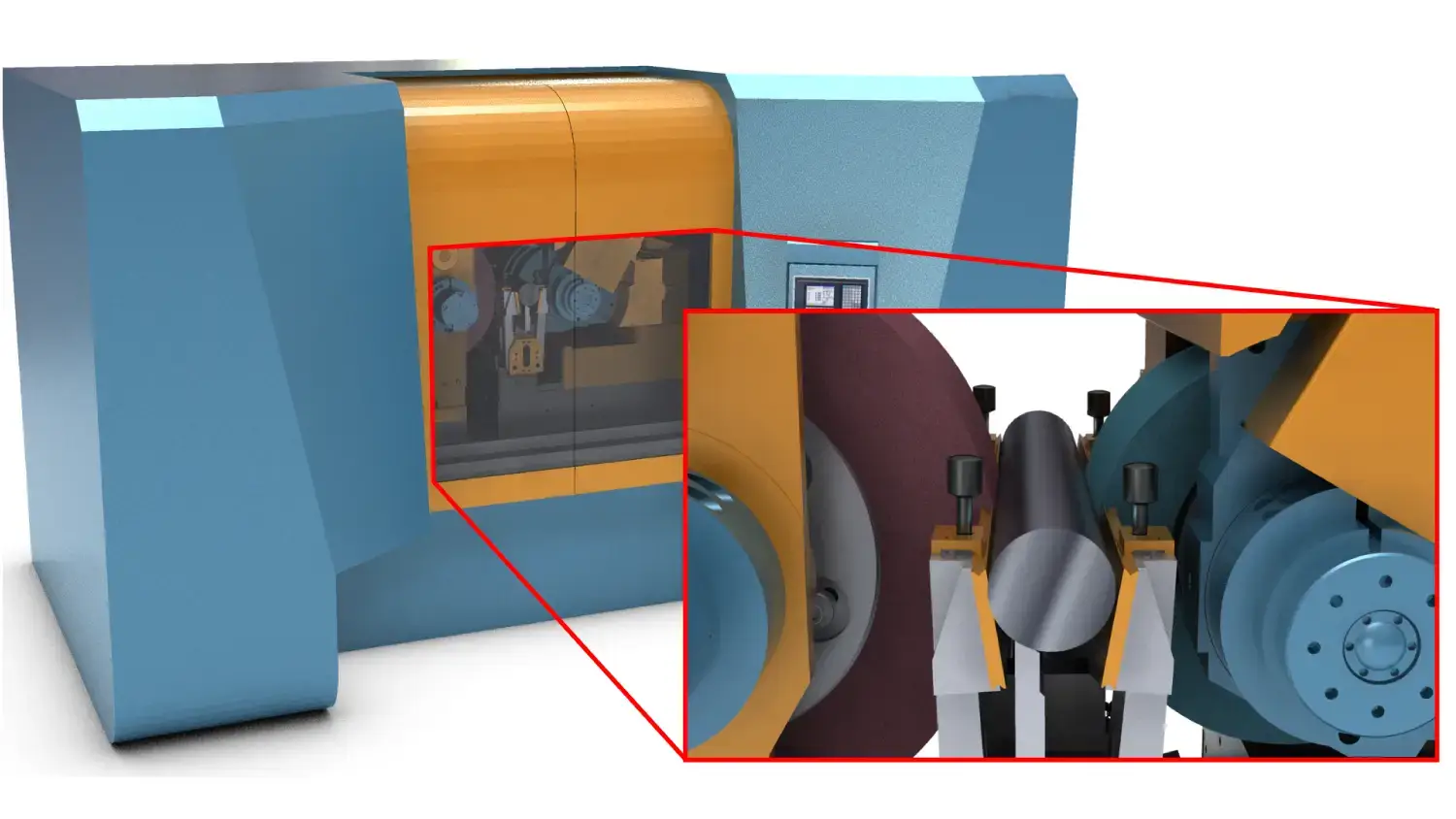

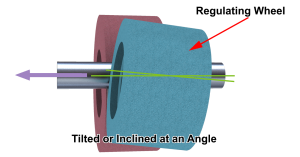

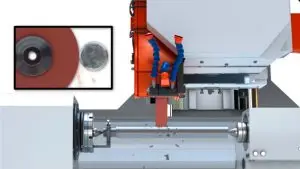

The THORS Centerless Grinding I course introduces learners to the basic functions, components, and terminology associated with centerless grinding machines. This course addresses the axis coordinate system in centerless grinding, emphasizing its critical role in machine control.

Who will benefit from this centerless grinding course?

Manufacturing Engineers, Design Engineers, Estimating Teams, Quality, Purchasing, Small Business Owners and others at organizations that operate centerless grinding machines will benefit from the centerless grinding course.

Course Classification

*THORS uses the Bloom’s Taxonomy Methodology for our course development.

Certificate Awarded for Centerless Grinding I Parameters

*upon successful completion

Related Posts

Waterjet Cutting: The Components that Produce Precision

Waterjet cutting typically utilizes a combination of water mixed with an abrasive material to perform the cut, and is used in industries around the world,

How Can THORS Help Enhance Your College Education?

THORS Academy can help enhance your college education in a number of ways. Imagine being in a college class and being told you have a

Women in Manufacturing: An Interview with Kavita Krishnamurthy

As part of a tribute to women in manufacturing, we at THORS eLearning Solutions decided to showcase one of our own, Kavita Krishnamurthy. Kavita is