Course Description

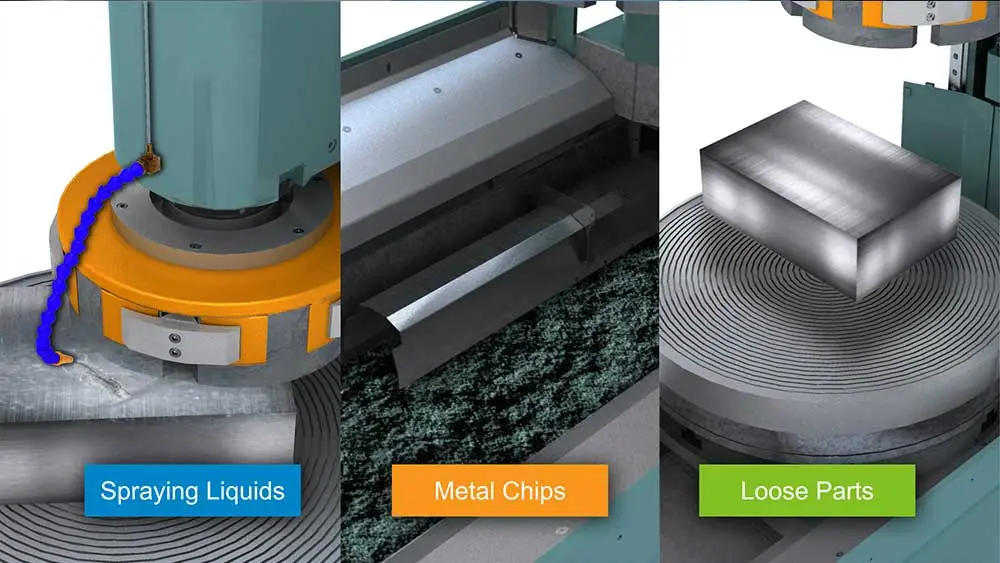

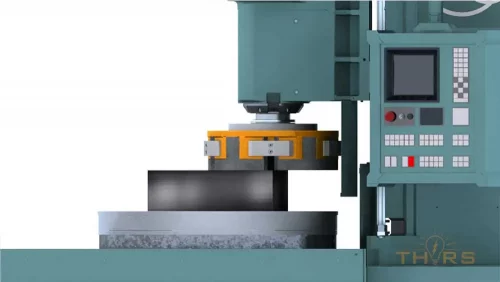

The Rotary Surface Grinding Video Series 2 introduces learners to concepts that are important to the rotary surface grinding process, such as cutting parameters, basic program codes, and macro variable programming. Important safety, best practices, and troubleshooting techniques for surface grinding operators are presented.

Who will benefit from this Rotary Surface Grinding Process video series?

Operators, Inspectors, Sales, and Purchasing.

Course Classification

*THORS uses the Bloom’s Taxonomy Methodology for our course development.

Certificate Awarded for Rotary Surface Grinding Video Series 2

*upon successful completion

Related Posts

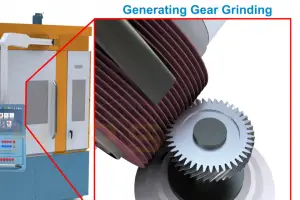

Generating Gear Grinding Process Insights

Introduction Generating gear grinding is a precision machining process that is crucial in manufacturing, especially for producing gears. Gears are indispensable components of many machines and

How Can THORS Help Enhance Your College Education?

THORS Academy can help enhance your college education in a number of ways. Imagine being in a college class and being told you have a

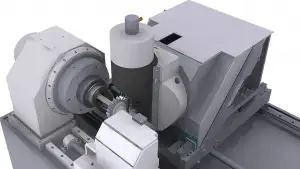

Cylindrical Grinding Innovations: Revolutionizing Precision Machining

Cylindrical Grinding Innovations Cylindrical grinding innovations have revolutionized the machining process. Cylindrical grinding is a machining process used to achieve high levels of dimensional accuracy