Course Description

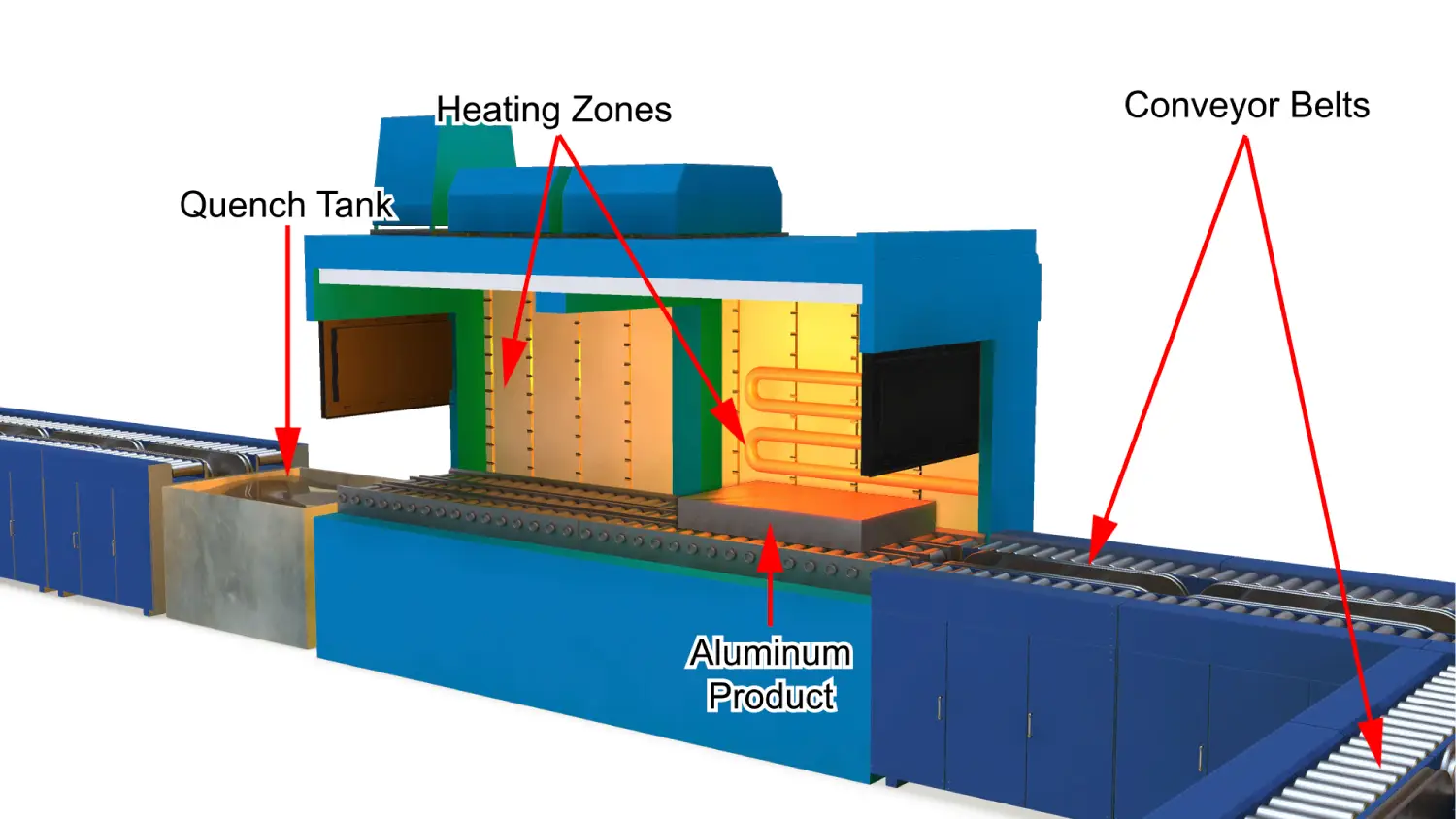

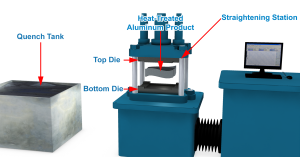

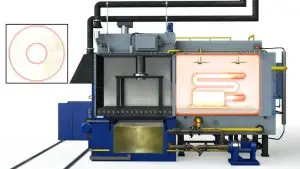

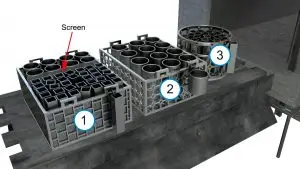

The THORS Heat Treating Aluminum Products course provides an overview of how aluminum alloys respond to heat treatment. It covers phase diagrams, alloys designations, temper designations, recommended oven types, and quench media selection. Learners will explore different heat treating processes for aluminum alloys, along with key post-processing steps such as straightening. The course also addresses common defects and basic troubleshooting strategies.

Who will benefit from this heat treating aluminum products course?

Operators, metallurgists, heat treat supervisors, and managers, and professionals from quality, manufacturing, engineering, design, testing, purchasing, and sales functions

Course Classification

*THORS uses the Bloom’s Taxonomy Methodology for our course development.

Certificate Awarded for Heat Treating Aluminum Products

*upon successful completion

Related Posts

Developing Soft Skills in the Tech Industry

Soft skills in the tech industry, where precision and expertise are paramount, might seem secondary. However, soft skills such as communication, teamwork, and problem-solving, play

How THORS Courses Helped a Mechatronics Student in Germany

Sasshank is an international student attending University in Germany where he studies mechatronics engineering. He was born in Tamil Nadu, where he attended various schools

5 signs you should invest in effective workforce training

In today’s constantly changing marketplace, the importance of workforce training has never been greater. Workforce training has the ability to not only increase workforce efficiency