Course Description

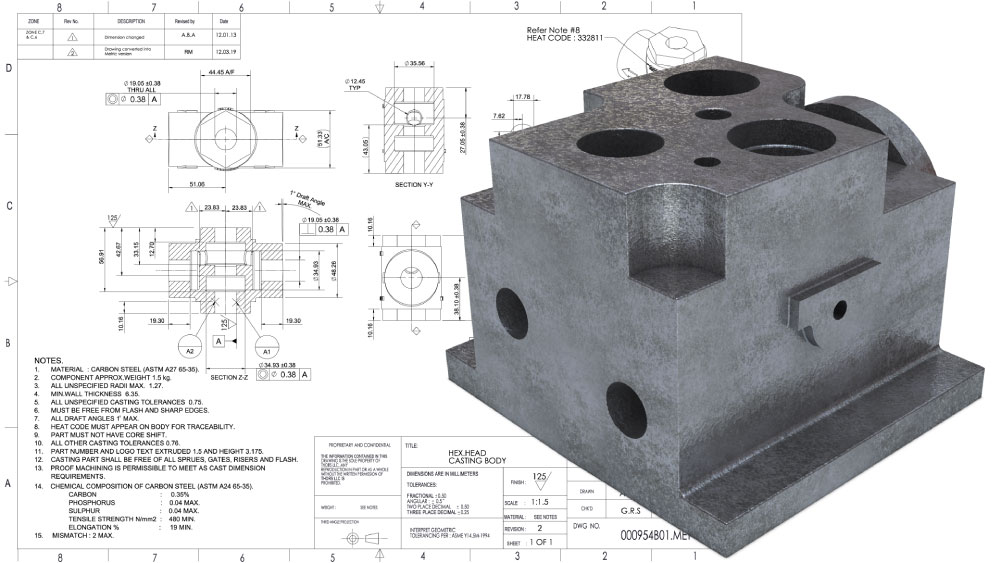

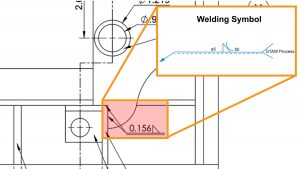

Engineering Drawings for Castings elaborates on the fundamental terminology associated with engineering drawings used when casting a product. Presented in THORS’ highly visual and interactive learning format, this course will help employees understand and interpret engineering drawings for castings.

Who will benefit from this Engineering Drawings for Castings course?

Engineering, manufacturing, quality, and purchasing personnel within any organization that produces parts using an engineering drawing.

Course Classification

*THORS uses the Bloom’s Taxonomy Methodology for our course development.

Certificate Awarded for Engineering Drawings for Castings

*upon successful completion

Related Posts

Entertainment in Education is the Future

Prepare to embark on an extraordinary adventure as we dive into the captivating world of the future of education. We will unravel the seamless integration

Training Programs are Critical to Attracting and Retaining Talent

In today’s rapidly changing business landscape, organizations face a unique set of challenges in finding, hiring, and retaining top talent. The tight labor market has

The Essential Skills of Modern Purchasing Professionals

In my professional career that spans more than three decades, I have had the privilege of working closely with purchasing. I can attest to the