Course Description

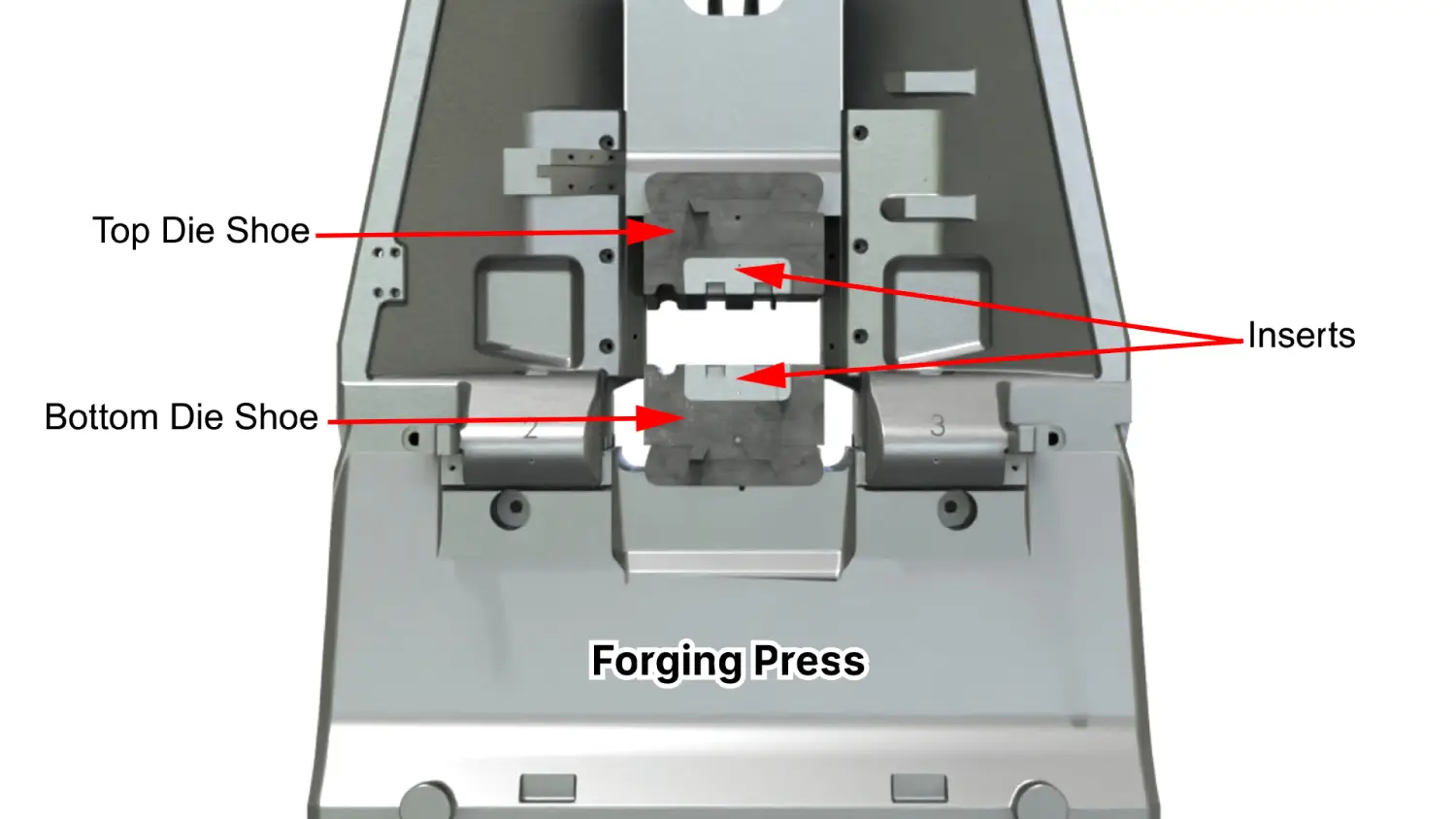

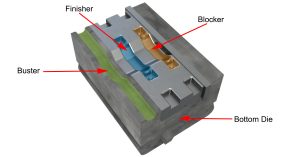

The THORS Forging Die Design Essentials course provides design parameters and best practices to maximize die tooling efficiency while minimizing cost factors. With a visually based format, this course focuses on process improvement for real-world forging die applications and process control scenarios.

Who will benefit from this forging dies course?

Quality, manufacturing, engineering, design, testing, purchasing, and sales functions at organizations that manufacture or utilize forging dies.

Course Classification

*THORS uses the Bloom’s Taxonomy Methodology for our course development.

Certificate Awarded for Forging Die Design Essentials

*upon successful completion

Related Posts

Developing Soft Skills in the Tech Industry

Soft skills in the tech industry, where precision and expertise are paramount, might seem secondary. However, soft skills such as communication, teamwork, and problem-solving, play

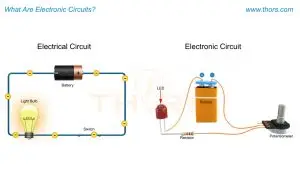

The Evolution of Resistor Technology: From Wire to What’s Next?

Understanding the evolution of resistor technology highlights their crucial role in electronic circuits and how their advancements have shaped modern electronics. It also drives innovation

Women in Manufacturing: An Interview with Kavita Krishnamurthy

As part of a tribute to women in manufacturing, we at THORS eLearning Solutions decided to showcase one of our own, Kavita Krishnamurthy. Kavita is