Course Description

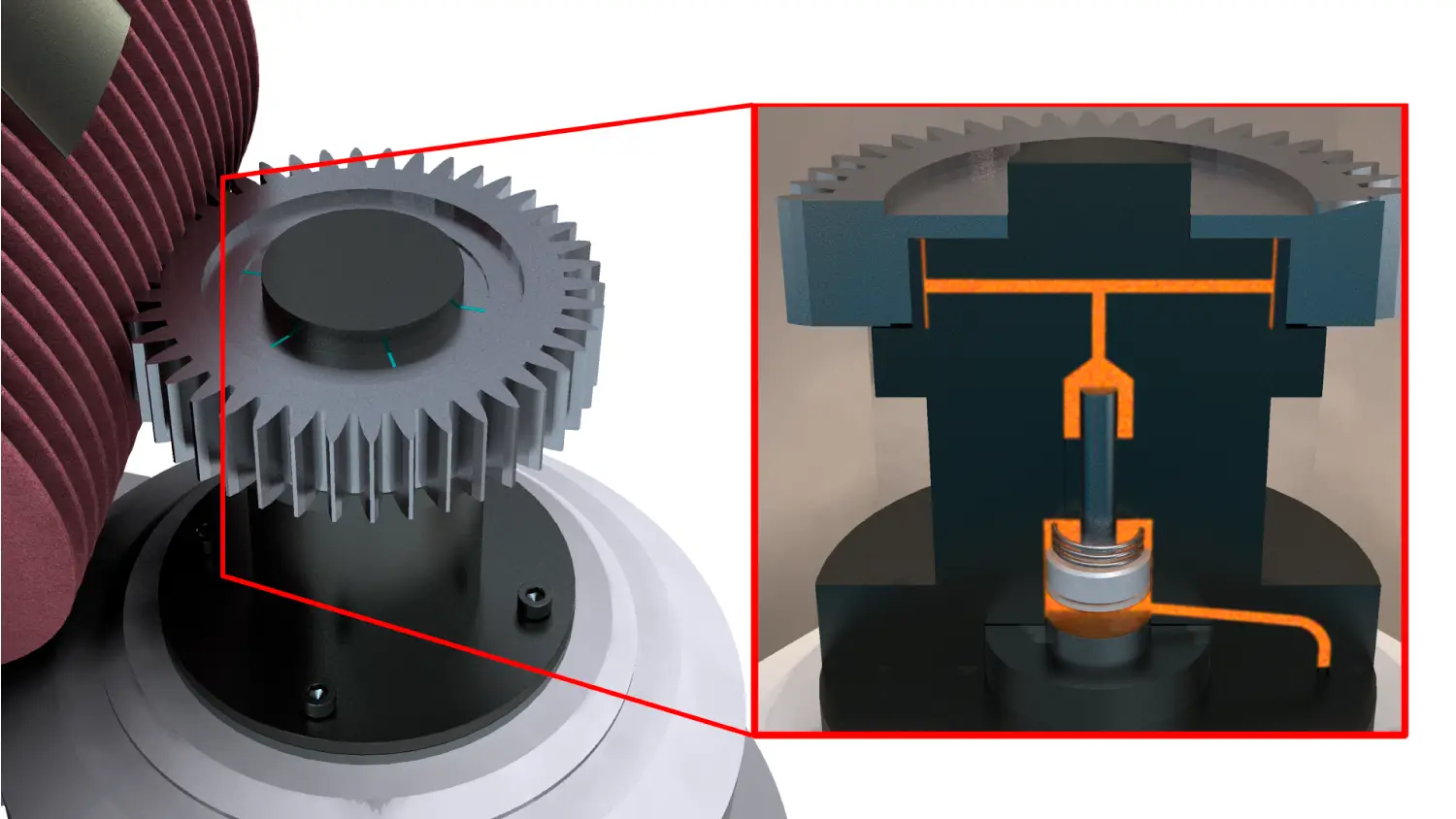

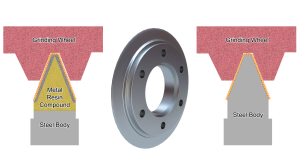

The THORS Generating Gear Grinding II course offers a comprehensive overview of gear grinding wheels, detailing their structure and characteristics, along with an exploration of various types of dressing tools and workholding devices used in generating gear grinding. Designed as an extension of the Generating Gear Grinding I course, this course enhances the understanding of learners in the key aspects of the functioning of gear grinding tools that are critical for efficient gear grinding operations.

Who will benefit from this generating gear grinding tools course?

Manufacturing Engineers, Design Engineers, Estimating Teams, Quality, Purchasing, Small Business Owners, and others at organizations that operate gear grinding machines will benefit from the generating gear grinding course. |

Course Classification

*THORS uses the Bloom’s Taxonomy Methodology for our course development.

Certificate Awarded for Generating Gear Grinding II

*upon successful completion

Related Posts

Orientation versus Onboarding: Understanding the Differences

When discussing “orientation versus onboarding”, it’s vital to recognize that, though frequently conflated, they serve distinct purposes in the professional environment. Despite both focusing on

Gear Hobbing Cutting Parameters to Optimize the Hobbing Process

What are the Primary Gear Hobbing Cutting Parameters? Primary gear hobbing cutting parameters include the radial feed rate, the axial feed rate, the work spindle

5 Ways to Reduce Human Errors in Manufacturing

We cannot change the human condition, but in manufacturing we can certainly improve the way people work, where they work, and what systems they use.