Course Description

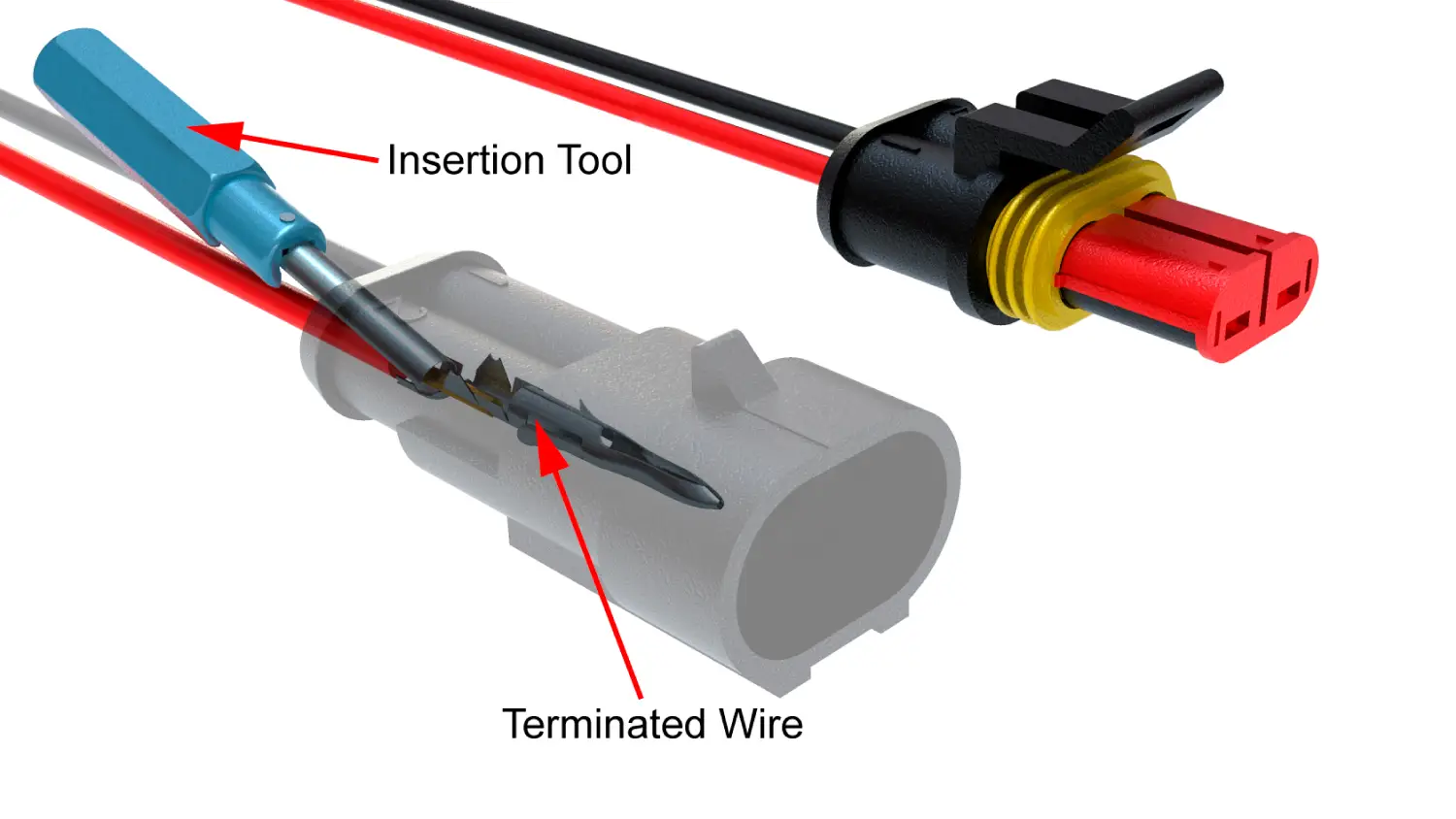

The THORS Wiring Harness Wire Processing course serves as a foundational guide to understanding the various processes such as cutting, stripping, wire termination, labeling, splicing, connector installation, braiding, taping, zip tying, heat shrinking, and sleeving involved in wiring harness wire processing. Presented in THORS’ highly visual and interactive learning format, this course enables learners to gain knowledge of wire preparation and wire protection for wiring harnesses.

Who will benefit from this wiring harness wire processing course?

Quality Assurance Professionals, Design Engineers, Automotive Engineers, Maintenance Technicians, Regulatory Compliance Officers, and Manufacturing Engineers

Course Classification

*THORS uses the Bloom’s Taxonomy Methodology for our course development.

Certificate Awarded for Wiring Harness Wire Processing

*upon successful completion

Related Posts

How Can THORS Help Enhance Your College Education?

THORS Academy can help enhance your college education in a number of ways. Imagine being in a college class and being told you have a

Gear Manufacturing: Back to Basics

Gears are thought to be one of the oldest components known to humankind. Early examples of gears trace back to the fourth century BC in China. Since then,

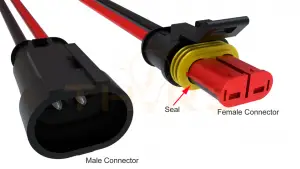

Top 5 Applications of Sealed Connectors in Wiring Harnesses

Sealed connectors in a wiring harness are protective components designed to prevent environmental contaminants such as water, dust, and chemicals from compromising electrical connections. The