Course Description

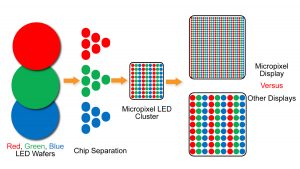

Semiconductor manufacturing is a complex process involving many steps. The THORS Semiconductor Manufacturing I course covers two crucial steps in the manufacturing process: silicon wafer fabrication and semiconductor deposition. The silicon wafer fabrication step encompasses single crystal silicon growth, wafer grinding, wafer slicing, wafer edge grinding, wafer lapping, wafer etching, and wafer polishing. The semiconductor deposition step includes various important types of deposition processes in semiconductor manufacturing. To enhance the learning experience, the course contains interactive quizzes, allowing learners to test their knowledge and retention of visually engaging content.

Who will benefit from this semiconductor manufacturing course?

Quality, manufacturing, engineering, design, testing, purchasing, and sales functions at organizations that require an understanding of how semiconductor devices are manufactured.

Certificate Awarded for Semiconductor Manufacturing I

*upon successful completion

Related Posts

Benefits of eLearning in Manufacturing

In the world of manufacturing, training is essential. Every employee needs to understand how to use equipment, follow procedures, and maintain quality standards. With the advent

How Does Your Television Respond to a Remote Control?

Have you ever wondered how your television understands and responds to the commands that are given to the remote control? Breaking apart a television remote

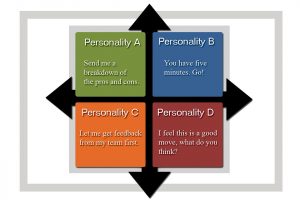

Knowing Customer’s Personality Style Adds Value

Maybe you think the value is obvious. If you can speak the same “language” as the person you are talking with, you can build trust