Course Description

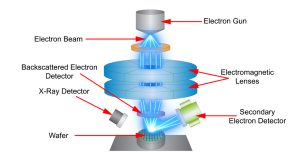

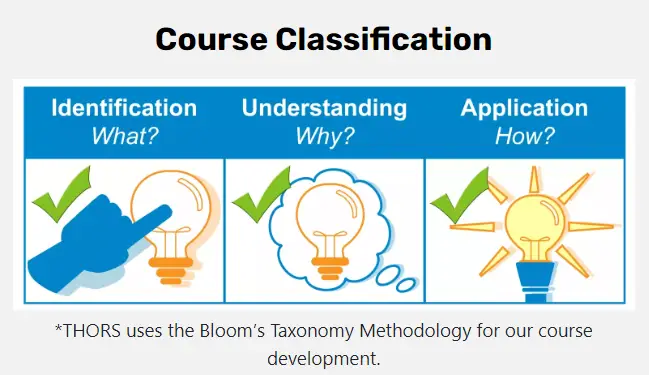

The THORS Semiconductor Metrology Instruments course introduces the learners to the various instruments used in semiconductor testing. This course focuses on wafer inspection systems, which are used for identifying defects, and process control metrology instruments, which are used for measuring various aspects of semiconductor manufacturing processes. Presented in THORS’ highly visual and interactive learning format, this course will equip the learner with a foundational knowledge of semiconductor metrology.

Who will benefit from this semiconductor metrology instruments course?

Quality, manufacturing, engineering, design, testing, purchasing, and sales functions at organizations that require a comprehensive understanding of the instruments and techniques involved in semiconductor metrology from wafer inspection systems to process control metrology.

Certificate Awarded for Semiconductor Metrology Instruments

*upon successful completion

Related Posts

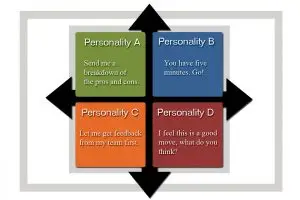

Knowing Customer’s Personality Style Adds Value

Maybe you think the value is obvious. If you can speak the same “language” as the person you are talking with, you can build trust

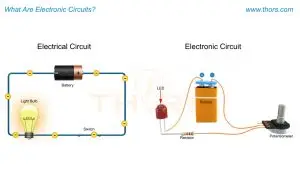

The Evolution of Resistor Technology: From Wire to What’s Next?

Understanding the evolution of resistor technology highlights their crucial role in electronic circuits and how their advancements have shaped modern electronics. It also drives innovation

Semiconductor Chip Shortage Significance

In an increasingly interconnected world driven by technological advancements, a looming crisis has captured the attention of industries, governments, and individuals alike: the semiconductor chip