Course Description

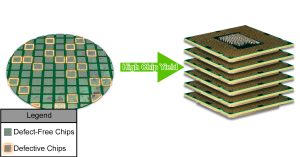

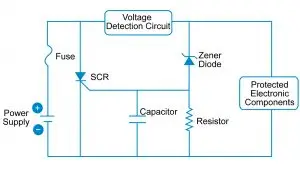

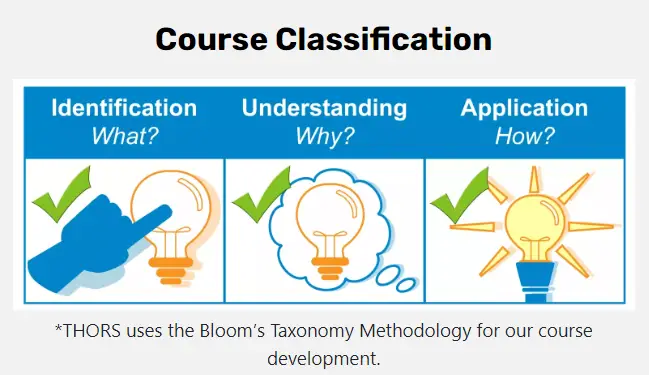

The THORS Semiconductor Metrology Basics course introduces the learners to the significance of testing in semiconductor manufacturing. This course focuses on key measurements in semiconductor metrology for defect inspection and process control. Presented in THORS’ highly visual and interactive learning format, this course will equip the learner with a foundational knowledge of semiconductor metrology.

Who will benefit from this semiconductor metrology course?

Quality, manufacturing, engineering, design, testing, purchasing, and sales functions at organizations that require a comprehensive understanding of the processes involved in semiconductor metrology from defect inspection to semiconductor manufacturing process metrology. |

Certificate Awarded for Semiconductor Metrology Basics

*upon successful completion

Related Posts

How Can THORS Help Enhance Your College Education?

THORS Academy can help enhance your college education in a number of ways. Imagine being in a college class and being told you have a

Safely Handling Lithium-Ion Batteries: 10 Tips

Safely handling Lithium-Ion batteries is important. These batteries power everything from cellphones to Electric Vehicles (EVs). The lithium-ion battery’s efficiency, lightweight design, and great energy

Flexible Printed Circuit Boards (PCBs): Expanding Innovation

Flexible Printed Circuit Boards (PCBs) are expanding the horizons of innovation beyond the limitations of rigid PCBs. In the past, electronic devices were built by