Course Description

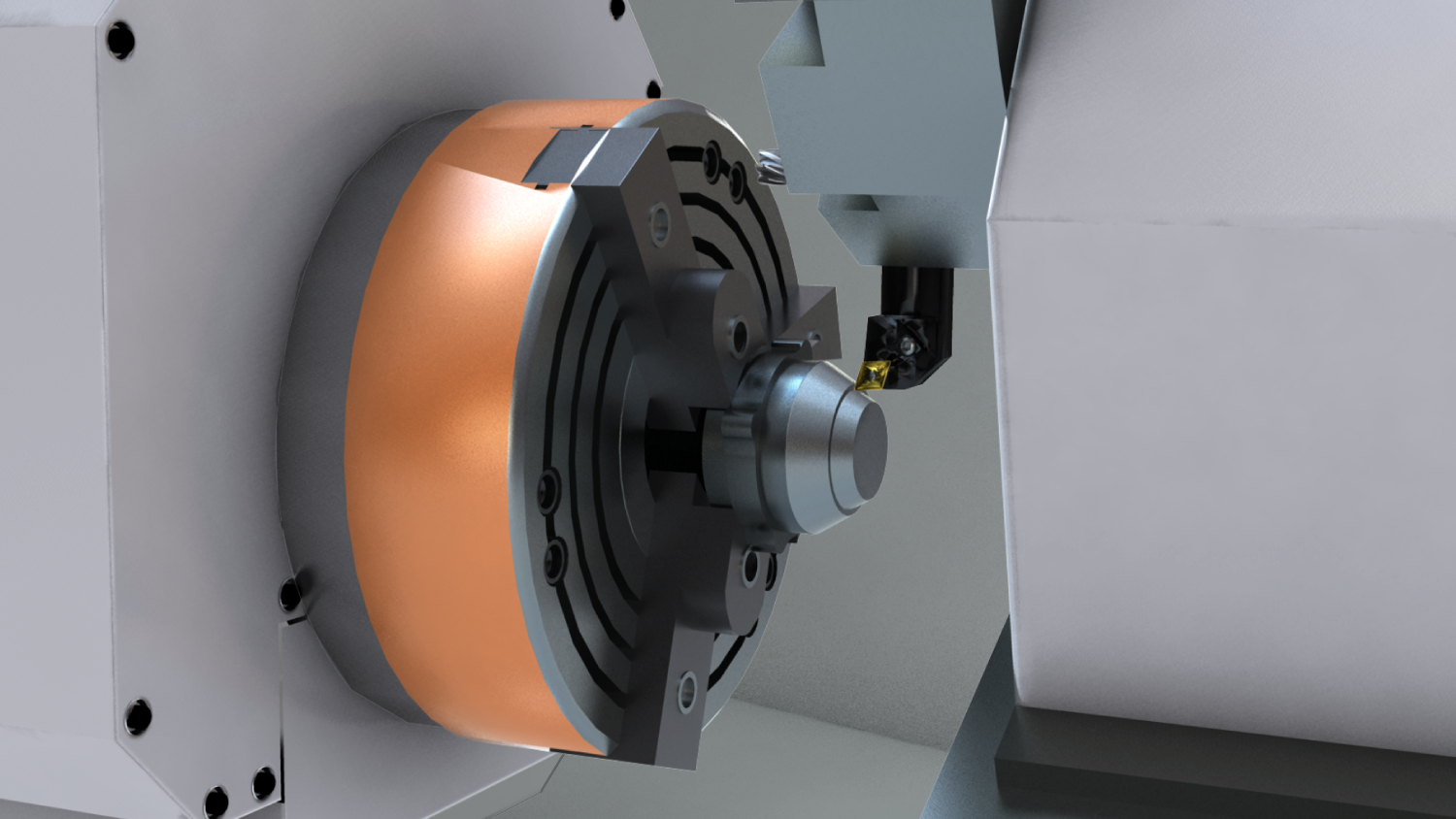

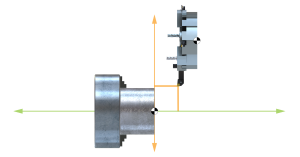

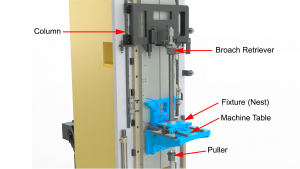

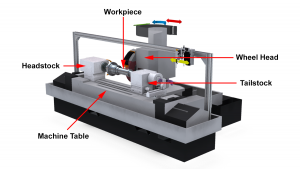

The Turning Center Video Series 2 introduces learners to the components of turning tool and workpiece clamping. The series also presents concepts important to the turning process, such as cutting parameters, tool offsets, and basic program codes, along with best practices and troubleshooting techniques.

Who will benefit from this Turning Center Clamping video series?

Operators, Inspectors, Sales, and Purchasing.

Course Classification

*THORS uses the Bloom’s Taxonomy Methodology for our course development.

Certificate Awarded for Turning Center Video Series 2

*upon successful completion

Related Posts

How THORS Courses Helped a Mechatronics Student in Germany

Sasshank is an international student attending University in Germany where he studies mechatronics engineering. He was born in Tamil Nadu, where he attended various schools

How Can THORS Help Enhance Your College Education?

How Can THORS Help Enhance Your College Education? THORS Academy can help enhance your college education in a number of ways. Imagine being in a

5 Ways to Reduce Human Errors in Manufacturing

We cannot change the human condition, but in manufacturing we can certainly improve the way people work, where they work, and what systems they use.