Course Description

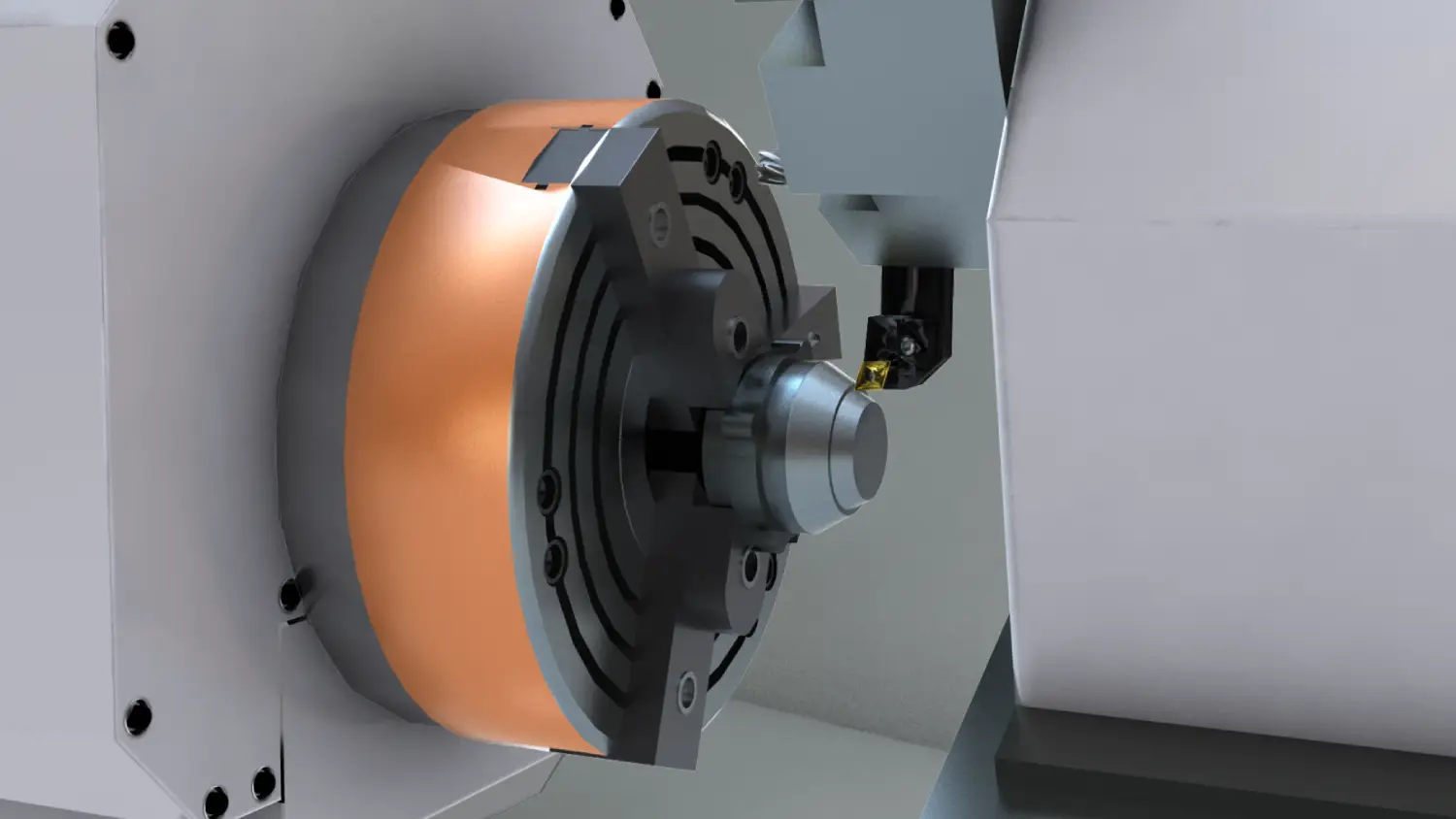

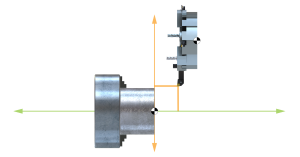

The Turning Center Video Series 2 introduces learners to the components of turning tool and workpiece clamping. The series also presents concepts important to the turning process, such as cutting parameters, tool offsets, and basic program codes, along with best practices and troubleshooting techniques.

Who will benefit from this Turning Center Clamping video series?

Operators, Inspectors, Sales, and Purchasing.

Course Classification

*THORS uses the Bloom’s Taxonomy Methodology for our course development.

Certificate Awarded for Turning Center Video Series 2

*upon successful completion

Related Posts

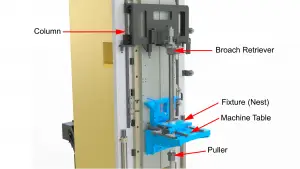

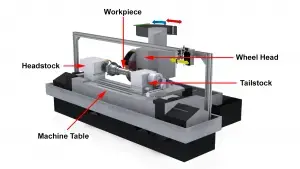

Cylindrical Grinding in Manufacturing is Fueled by Five Factors

In modern manufacturing, cylindrical grinding plays a crucial role, emerging as a key process. Let’s explore the intricate world of cylindrical grinding; its diverse applications,

The Role of Virtual Reality in Technical Training

In the rapidly evolving landscape of technology and industry, virtual reality (VR) in technical training is leading a revolutionary transformation in how professionals are trained.

How THORS Courses Helped a Mechatronics Student in Germany

Sasshank is an international student attending University in Germany where he studies mechatronics engineering. He was born in Tamil Nadu, where he attended various schools