Course Description

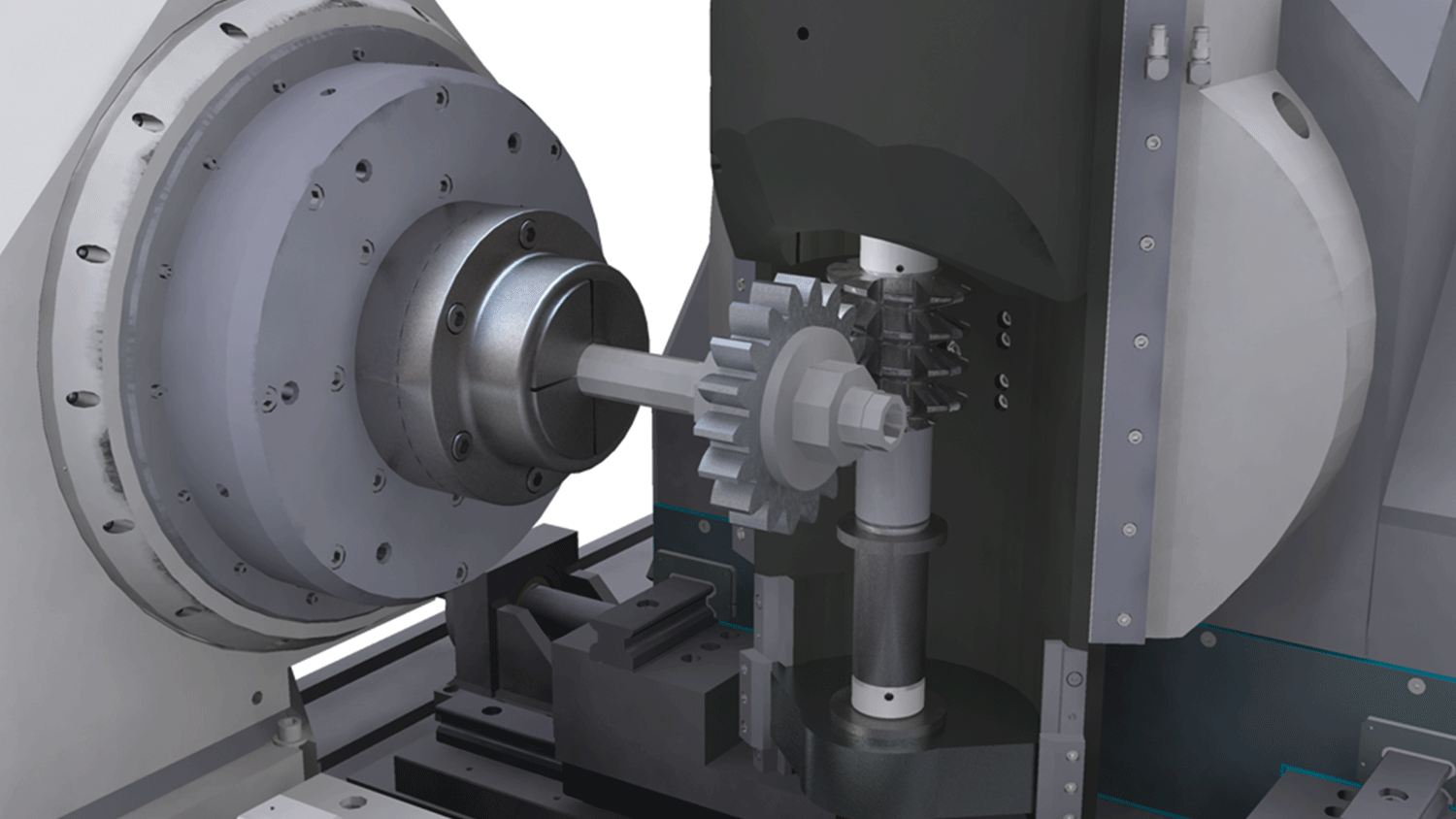

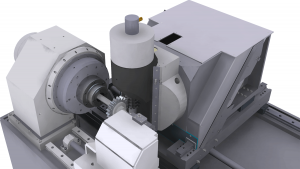

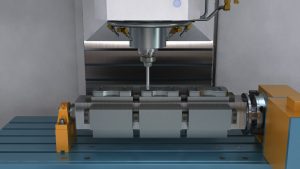

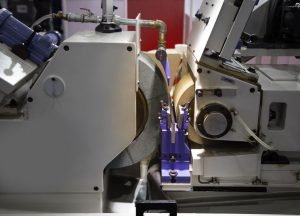

The Gear Hobbing Video Series 2 course introduces learners to a basic setup sheet for the hobbing process and addresses important concepts, such as cutting parameters and Human Machine Interface (HMI) programming. Finally, some crucial best practices and troubleshooting techniques for gear hobbing machines are presented.

Who will benefit from this Gear Hobbing setup and programming video series?

Operators, Inspectors, Sales, and Purchasing.

Course Classification

*THORS uses the Bloom’s Taxonomy Methodology for our course development.

Certificate Awarded for Gear Hobbing Video Series 2

*upon successful completion

Related Posts

Centerless Grinding: The Role of Grinding and Regulating Wheels

The synchronized movement of the two wheels in centerless grinding is important. The grinding wheel and the regulating wheel each has a specific role to

How THORS Courses Helped a Mechatronics Student in Germany

Sasshank is an international student attending University in Germany where he studies mechatronics engineering. He was born in Tamil Nadu, where he attended various schools

5 ways to reduce human errors in manufacturing

We cannot change the human condition, but in manufacturing we can certainly improve the way people work, where they work, and what systems they use.