What is gear hobbing?

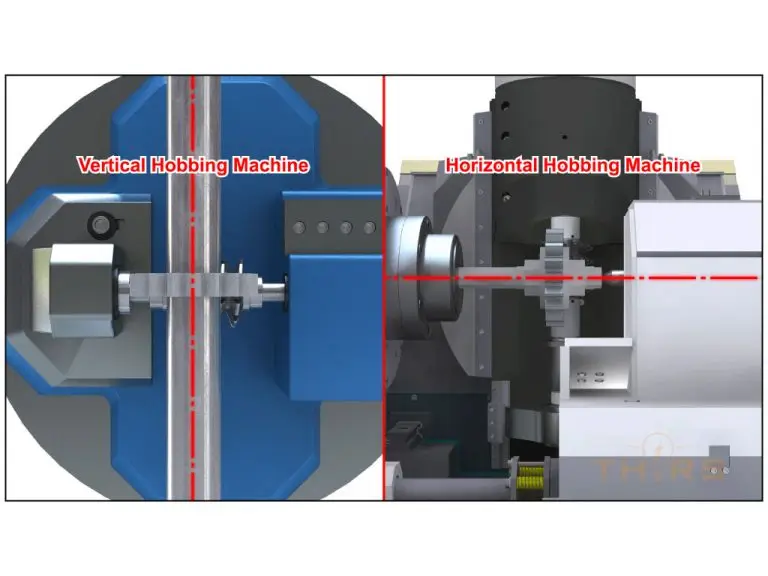

Gear hobbing is considered a generating process and is the most common method of producing teeth in gears of all sizes. The gear hobbing equipment and tools utilized for an operation vary based on the gears being produced. The process depends on precisely coordinated continuous rotations and linear motion between the workpiece and the cutting tool called the hob, or hobbing cutter. There are both vertical and horizontal hobbing machines, based on the orientation of the workpiece during the process.

What equipment is used for gear hobbing?

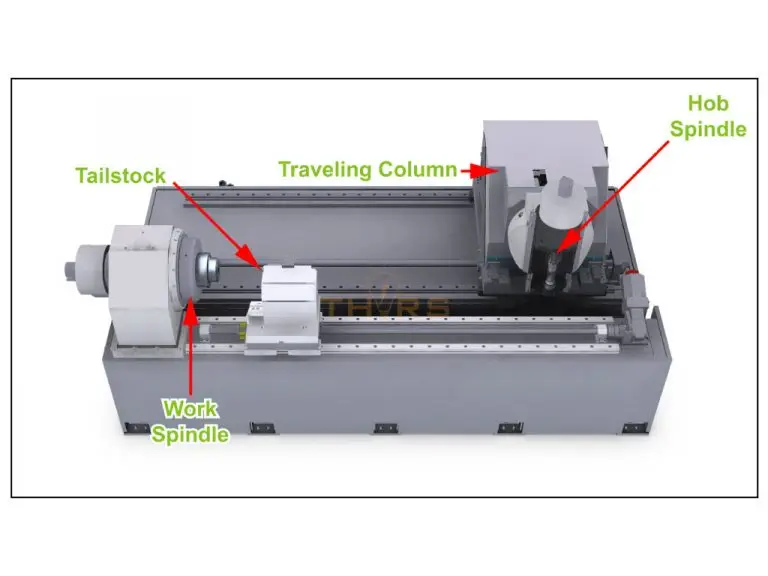

The equipment, or larger components, of a gear hobbing machine are designed to facilitate the precise positioning of the workpiece and hobbing cutter. Most of the components are capable of rotating or shifting linearly as required.

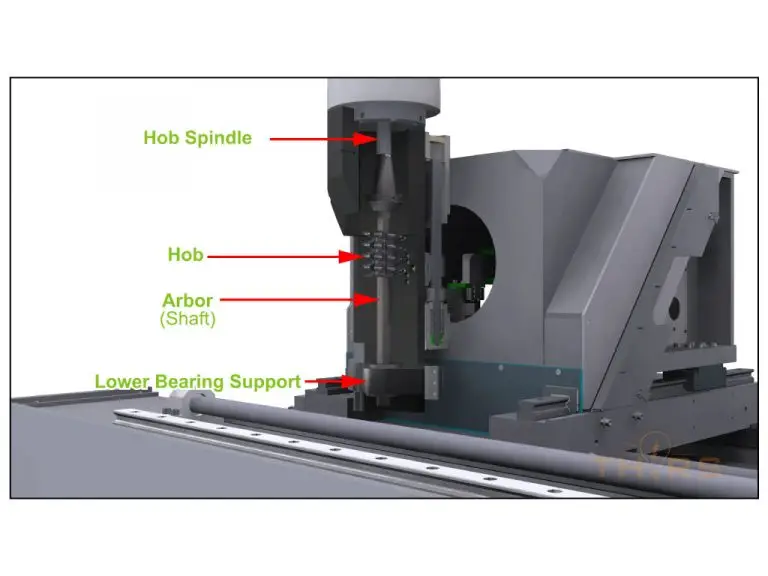

- The hob spindle holds the hobbing cutter and is oriented both linearly and radially on the machine.

- The tailstock engages the workpiece to provide stability during the hobbing process, in addition to providing extra security for the workpiece attachment to the work spindle.

- The traveling column shifts linearly and is adjusted to achieve the hobbing process.

- The work spindle holds the chuck, face driver, or collet system that is required to secure the workpiece to the spindle and may rotate clockwise (CW) or counterclockwise (CCW), depending on the operation.

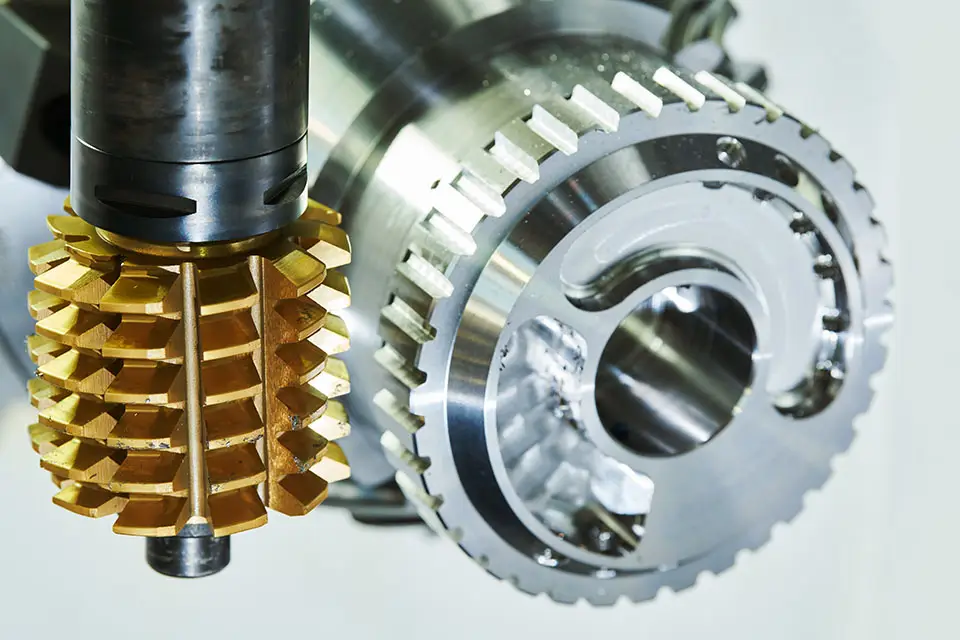

What tools are used for gear hobbing?

The tools, or tooling, used for gear hobbing are designed to be replaceable and specific to each operation. Gear hobbing equipment and tools are dependent on the required final gear part.

- Hobs, or hobbing cutters, are the cutting tools used in hobbing and come in a variety of shapes and configurations.

- The hob spindle holds the hobbing cutter and is oriented both linearly and radially on the machine.

- The arbor, or shaft, holds the hobbing cutter and is clamped into the hob spindle and captured by the lower bearing support.

- The lower bearing support, which holds the arbor at the bottom, can be detached to change the tools.

Learn more about gear hobbing equipment and tools in THORS’ Gear Hobbing Video Series 1.