Course Description

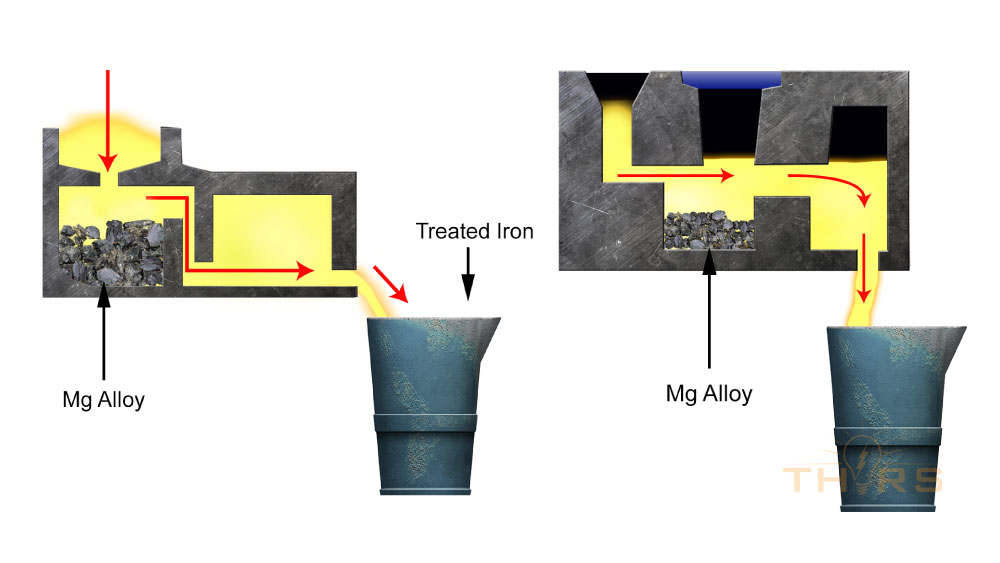

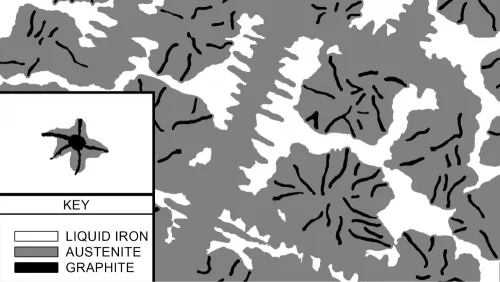

Ductile Iron Fundamentals introduces the learner to the properties, processes, and terminology associated with ductile iron production. This course also includes defect analysis of the manufactured product. Presented in THORS’ highly visual and interactive learning format, this course will help foundry employees become familiar with the important equipment processing steps associated with their profession.

Who will benefit from this Ductile Iron course?

Companies, individuals, or educational institutions that require an understanding of the terminology, properties, processes, and quality improvement procedures associated with ductile iron foundries.

Course Classification

*THORS uses the Bloom’s Taxonomy Methodology for our course development.

Certificate Awarded for Ductile Iron Fundamentals

*upon successful completion

Related Posts

eLearning Support for On-Site Training

eLearning has emerged as a revolutionary force in the realm of learning and professional development, evolving into an imperative tool in today’s competitive landscape. The

The Role of eLearning in Compliance Training

In today’s fast-changing business environment, effective compliance training is more crucial than ever. eLearning in compliance training has emerged as a powerful tool for ensuring

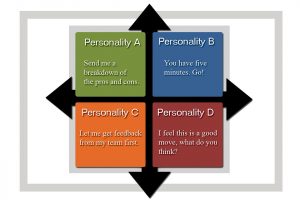

Knowing Customer’s Personality Style Adds Value

Maybe you think the value is obvious. If you can speak the same “language” as the person you are talking with, you can build trust