Course Description

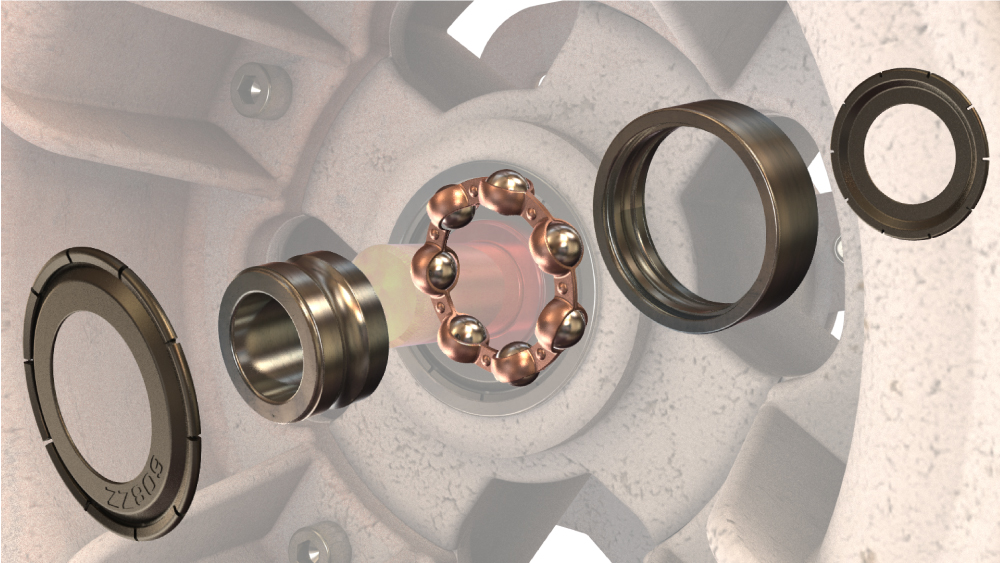

Bearing Fundamentals introduces learners to the basic components, considerations, and types of bearings used in the industry. In this course, there are multiple ways in which the fundamentals of bearings are presented such as with 3D animations, 3D/2D models, and GIFs. This course contains material which is suitable for those new to bearings and those who have experience in the industry.

Who will benefit from this Bearings course?

Equipment Designers; Equipment Maintenance Professionals; Engineering Students.

Course Classification

*THORS uses the Bloom’s Taxonomy Methodology for our course development.

Certificate Awarded for Bearing Fundamentals

*upon successful completion

Related Posts

Training Programs are Critical to Attracting and Retaining Talent

In today’s rapidly changing business landscape, organizations face a unique set of challenges in finding, hiring, and retaining top talent. The tight labor market has

eLearning Support for On-Site Training

eLearning has emerged as a revolutionary force in the realm of learning and professional development, evolving into an imperative tool in today’s competitive landscape. The

Benefits of eLearning in Manufacturing

In the world of manufacturing, training is essential. Every employee needs to understand how to use equipment, follow procedures, and maintain quality standards. With the advent