Course Description

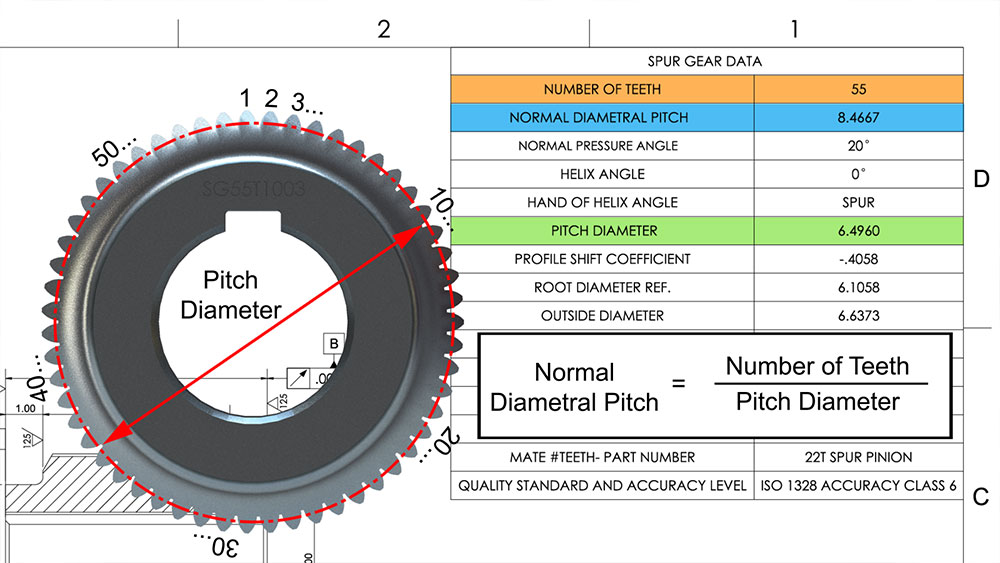

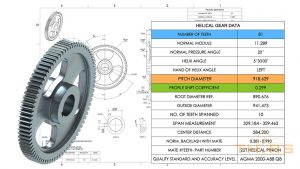

The THORS course, Engineering Drawings for Spur and Helical Gears, teaches the fundamental concepts needed to read and interpret a gear drawing. Commonly used terms, such as those found in a gear data block, associated with gear features, and in notes, are explained to enhance the understanding of drawing requirements to manufacture mating gear parts.

Who will benefit from this Engineering Drawings for Spur and Helical Gears course?

Manufacturing, quality, engineering, and purchasing functions in any organization that manufactures a gear component to an engineering drawing or print.

Course Classification

*THORS uses the Bloom’s Taxonomy Methodology for our course development.

Certificate Awarded for Engineering Drawings for Spur and Helical Gears

*upon successful completion

Related Posts

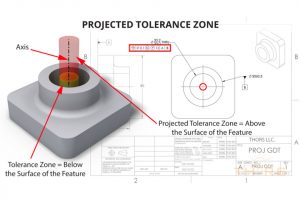

Beyond Symbols: Fluency in GD&T Decreases Cost

Due to the complex nature of the geometric dimensioning and tolerancing (GD&T) standard, a company’s bottom line profitability can be affected as a result of reading and interpreting

Upskilling in the Manufacturing Industry with THORS

In today’s rapidly evolving manufacturing industry, staying up to date with the latest technologies and processes is crucial to remaining competitive. Upskilling in the manufacturing industry

Certificate Programs vs Completion Certificates

Certificate programs and completion certificates are both types of educational programs that can provide valuable training and skills to individuals in a variety of fields.