When having discussions within the Value Methodology phases, it is important for your value study teams to use the correct terminology for Value, Function, and Resources.

These terms have been updated as follows:

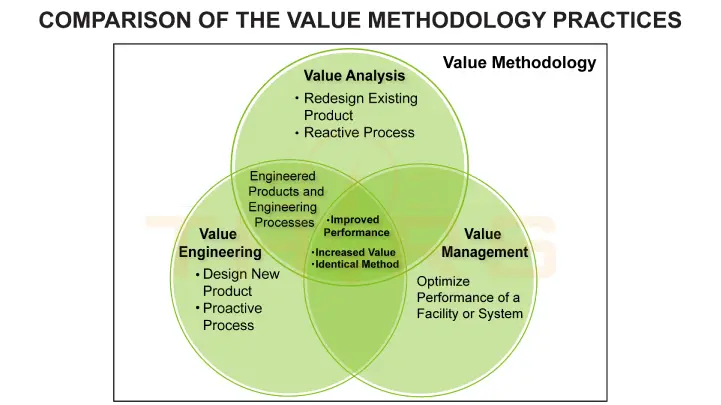

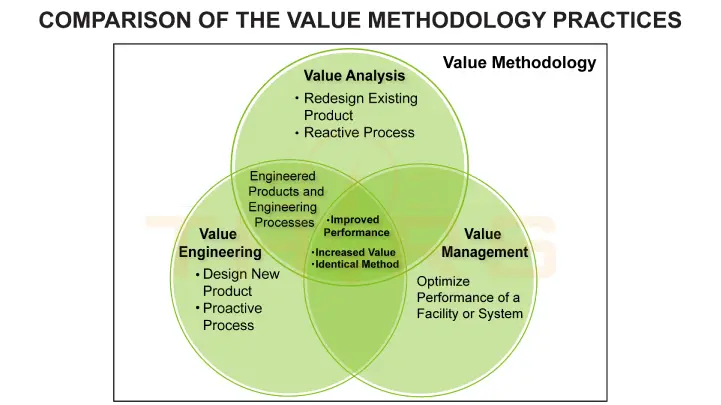

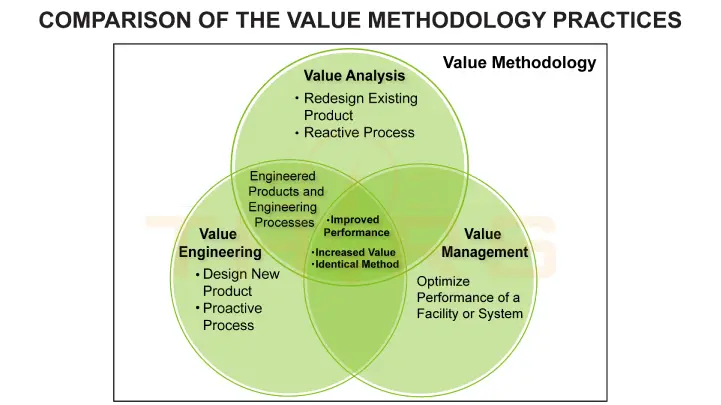

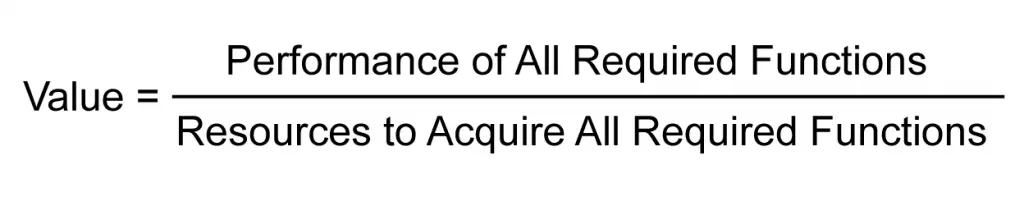

Value is a measure of how effectively and efficiently a project satisfies its performance requirements.

Function is the specific purpose or intended use for any product or process that makes it work or sell.

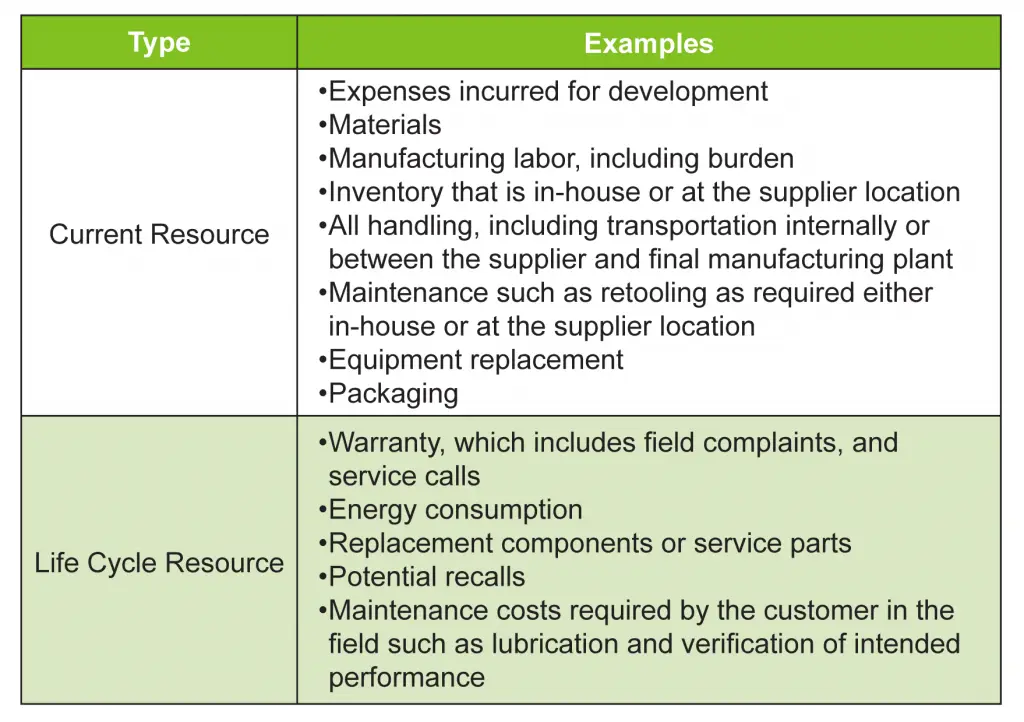

Resources typically relate to cost, but not always. Resources that must be considered in a manufactured product include current resources and life cycle resources over the life of the product or process.

Armed with a working knowledge of VAVE terminology, as well as the Value Methodology revisions for 2025, teams can focus on optimizing quality, cost, performance, risk, and schedule of a project; as well as driving innovation and tackling new initiatives surrounding reducing expenses and managing the impact of rising tariff costs.

Read more about how one of our customers is doing just that in our related blog, How Using Value Methodology Can Help You Manage Rising Tariff Costs.

What is Takt Time in Manufacturing? Takt time for manufacturing, also known as takt, is a term that describes the time available to complete a…

What is cycle time? In manufacturing, cycle time is the time spent within a single operational step during the process of making a complete product or…

Using Value Methodology (VM) principles has helped one of our customers determine ways to manage rising tariff costs. This scenario is further explained at the…

Individuals can sign up for courses or course bundles from our course catalog. Fill out the form to request a representative to contact you to discuss your specific needs.

Corporations, trade organizations, and educational institutions can receive special pricing and group setup. Group administrators have access to course activity reports for their learners. Fill out the form to request a custom demo or get more information.