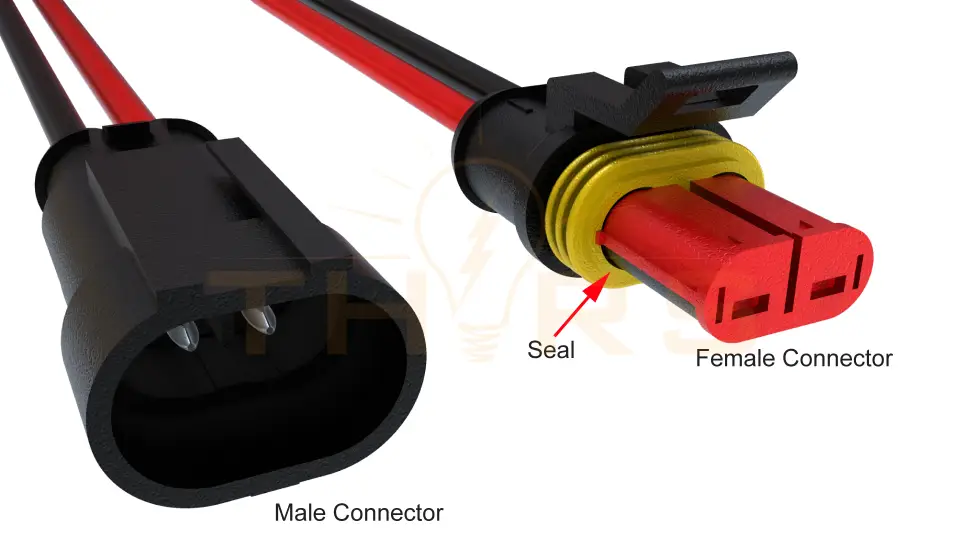

Sealed connectors in a wiring harness are protective components designed to prevent environmental contaminants such as water, dust, and chemicals from compromising electrical connections. The applications of sealed connectors highlight their importance in ensuring long-term reliability, minimizing the risk of short circuits or corrosion, and maintaining the overall performance of electrical systems, especially in harsh or demanding environments.

Ingress Protection (IP) rating is an international standard that classifies the degree of protection provided by enclosures of electrical equipment against the intrusion of solid objects and liquids.

Depending on the application, sealed connectors are typically rated IP67 or higher, offering complete protection against dust ingress and temporary immersion in water, making them suitable for rugged use in various fields.

The top 5 applications of sealed connectors include automobiles, aircraft, industrial machinery, agricultural equipment, and marine applications.

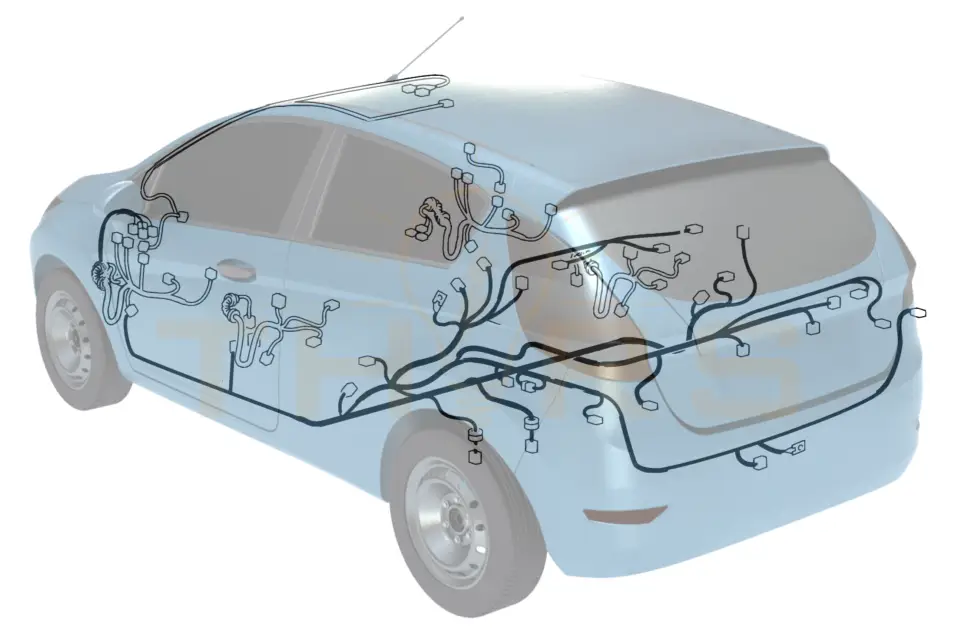

1. Automobiles

In automobiles, sealed connectors play a vital role in maintaining reliable electrical connections across various systems, including lighting, engine control units, sensors, and infotainment modules. Vehicles are exposed to a variety of harsh conditions, including extreme temperatures, vibrations, and exposure to water and dirt. Sealed connectors ensure that the electrical connections remain secure and functional, preventing failures that could lead to safety issues or costly repairs. Sealed Connectors are commonly used in areas prone to environmental exposure, such as engine compartments and undercarriages.

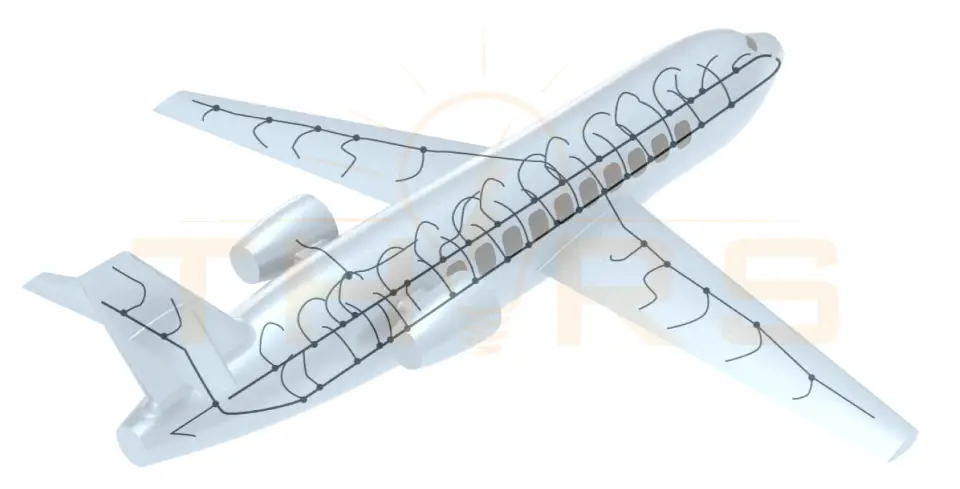

2. Aircraft

In aircraft, sealed connectors are essential for ensuring the reliability and safety of critical electrical systems, including engine control systems, avionics, and navigation equipment, communication, and lighting. Aircraft are exposed to a variety of harsh environmental conditions that can affect their electrical systems. These include extreme temperatures, high altitudes, severe weather, turbulence, icing conditions, and exposure to saltwater and pollutants. By providing robust protection against environmental hazards, sealed connectors help maintain the functionality and reliability of aircraft systems, which is crucial for safe and efficient operation.

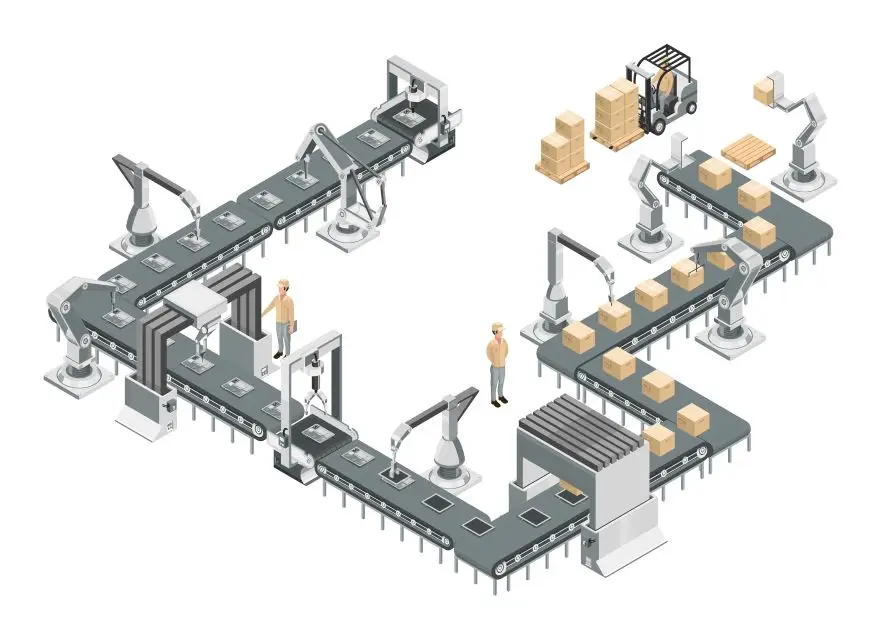

3. Industrial Machinery

In industrial machinery, sealed connectors are used to ensure safe electrical connections in environments where dust, oil, moisture, and mechanical vibrations are common. These connectors are critical for powering and controlling motors, sensors, actuators, and automation equipment. The harsh conditions in factories and processing plants demand connectors that can resist contamination and wear over time. Sealed connectors help prevent unplanned downtimes, enhance operational safety, and ensure consistent performance of machinery even in rugged and demanding industrial settings.

4. Agricultural Equipment

In agricultural equipment, sealed connectors are essential for maintaining reliable electrical connections in harsh field conditions. Tractors, harvesters, and other farm machinery often operate in environments filled with mud, dust, moisture, and vibrations. Sealed connectors protect sensitive electrical components from these contaminants, ensuring consistent performance of lighting, control systems, and engine electronics. The durability and environmental resistance of sealed connectors are critical for minimizing downtime and maintaining productivity during demanding agricultural operations.

5. Marine Applications

In marine applications, sealed connectors are vital for ensuring the reliability and safety of electrical systems exposed to water, salt, humidity, and vibration. Boats, ships, and offshore equipment are prone to moisture ingress and are challenging to maintain due to the constant exposure to saltwater, which can cause corrosion and electrical failures. Sealed connectors are designed to withstand these harsh conditions, providing reliable connections for navigation systems, communication equipment, and other critical electronic components on boats, ships and offshore equipment. The ability of sealed connectors to prevent water ingress and resist corrosion makes them ideal for use in marine wiring harnesses.

In conclusion, sealed connectors are indispensable components across a wide range of demanding applications. Their ability to protect against environmental contaminants and mechanical impacts makes them a reliable choice wherever electrical connections are exposed to challenging conditions. Whether you are driving through a rainstorm, flying at 30,000 feet, powering heavy-duty equipment on a factory floor, operating a harvester through muddy terrain, or navigating marine equipment through wet and corrosive conditions, sealed connectors provide the robust protection needed to keep your systems running smoothly and safely.

For an extensive introduction to connectors, their types, and other components of a wiring harness, refer to the THORS course on Wiring Harness Components.