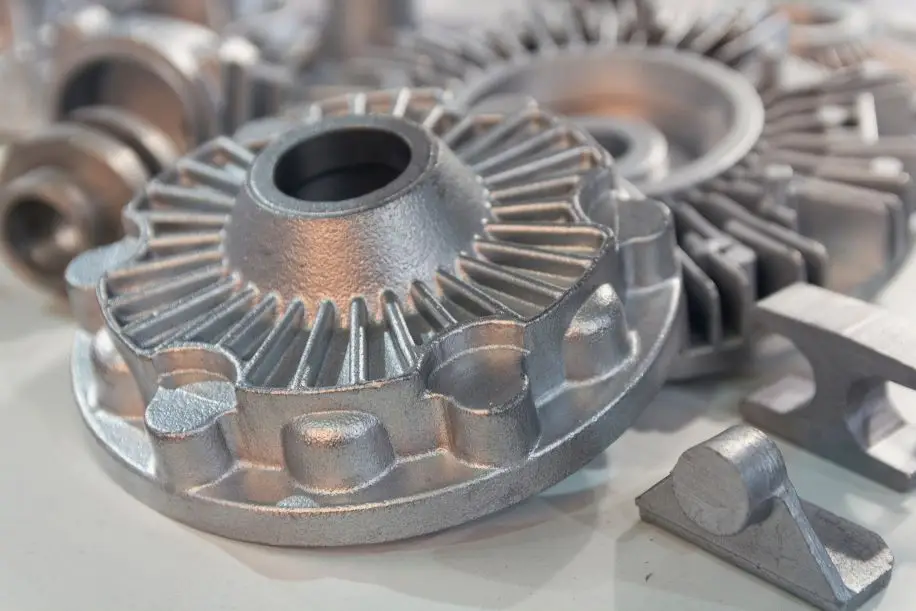

Shakeout may seem like a routine step in the casting process, but its impact goes far beyond simply removing mold material. In reality, it influences multiple aspects of casting efficiency, from cycle time and surface quality to material recovery and worker safety.

This article explores how a well-executed shakeout can significantly enhance the overall performance and productivity of the casting process.

Reduced Cycle Time

A well-performed shakeout plays a crucial role in reducing the total cycle time of the casting process. When shakeout is poorly executed, it results in excess residue on the casting, requiring additional cleaning steps that consume more time and resources. This highlights the importance of implementing efficient shakeout systems—typically automated, regardless of production scale. Automatic shakeout systems such as vibratory flat deck shakers significantly reduce cycle time by quickly and effectively separating the mold material from the casting with minimal manual intervention.

Minimal Cleaning and Rework

An efficient shakeout process leaves behind minimal mold residues on the casting surface. One of the most significant downstream effects of a poorly executed shakeout is the extensive cleaning required to remove fins, flash, and other surface defects. This not only prolongs the process but also increases the risk of over-cleaning, which can damage the casting and lead to rejection. A proper shakeout minimizes the need for rework, ensuring a smoother downstream workflow and maintaining product quality.

Quality Sand Reclamation

Shakeout has a direct impact on the effectiveness of sand reclamation. A well-executed shakeout is designed to enable immediate recovery of usable sand from the broken molds, which can then be routed for reclamation. In contrast, inefficient shakeout often results in mold residues being lost or contaminated during post-cleaning operations, leading to increased material waste. Efficient sand reclamation not only reduces environmental impact but also contributes to cost savings and sustainability.

Improved Workplace Safety and Ergonomics

An efficient shakeout system significantly enhances workplace safety and ergonomics. Automated systems reduce the need for workers to manually handle castings—especially while they are still hot—which minimizes the risk of burns, injuries, or heat-related illnesses. It also reduces workers’ exposure to toxic airborne particles commonly released during manual shakeout, contributing to a healthier work environment. Additionally, the reduction in physical strain improves overall worker productivity.

In the casting process, shakeout may seem like a simple transitional step, but it has a huge impact on the overall efficiency of a casting process. A well-executed shakeout not only reduces cycle time and minimizes cleaning and rework but also supports sustainable practices through efficient sand reclamation. Most importantly, it builds a safer and more ergonomic work environment for the workers. Curious to learn about the shakeout process? THORS’ Shakeout Basics is a comprehensive and engaging course that explores the process in detail.