Understanding the evolution of resistor technology highlights their crucial role in electronic circuits and how their advancements have shaped modern electronics. It also drives innovation in materials science: improving resistor efficiency and enabling further miniaturization, for example, for flexible printed circuit boards.

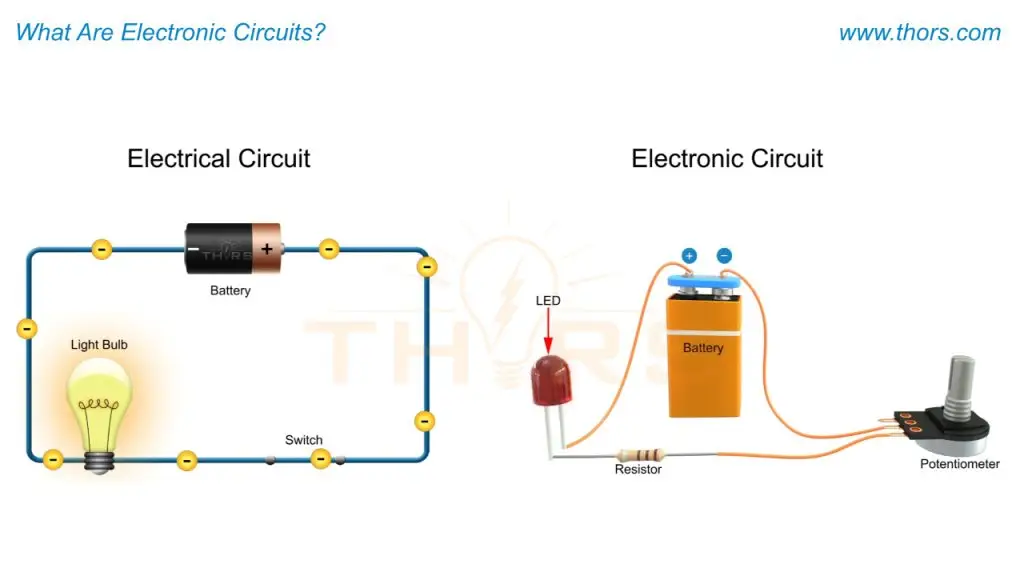

The flow of current in an electronic circuit often needs to be controlled to prevent damage. The evolution of the technology of resistors, a small electronic component, has significantly advanced this control, as they are placed in electronic circuits to limit the current. You can think of a resistor as a narrow section in a pipe, with the water flow representing the electrical current. In the narrow section, the water flows more slowly compared to the wider section. This is analogous to how resistors restrict the flow of current in a circuit. The resistance value indicates the amount of current that can be restricted in a circuit.

The resistors we use today have gone through a significant evolution over time. Let’s explore the early beginnings of resistors and the journey toward the sophisticated designs used in modern electronics.

Having an understanding about how the evolution of resistor technology can help engineers and designers make informed decisions about component selection, ensuring optimal performance and reliability in electronic circuits.

Early Days of Resistors

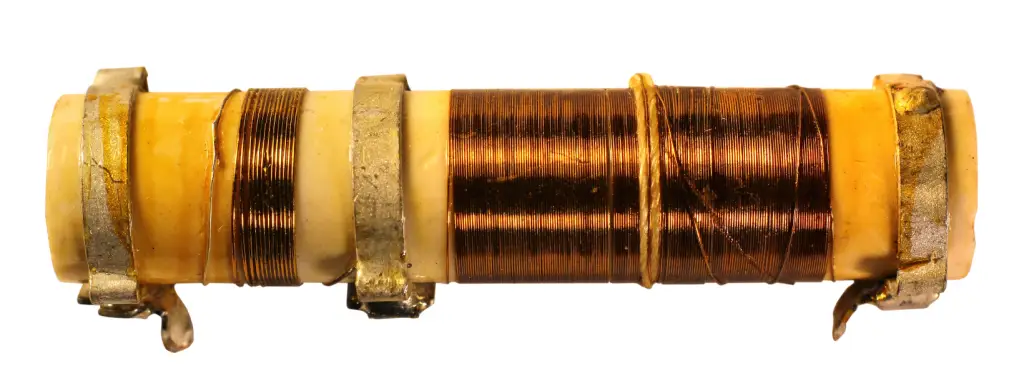

When Georg Simon Ohm first proposed the concept of resistance in 1827, resistors were not yet used as distinct electronic components in electronic circuits. In the early days of technology, resistors were made by using long pieces of wire or coils that had high resistance to electrical flow. These were often used in devices such as telegraphs and early radios. The wires were usually made from materials such as nichrome or materials that were good at resisting the flow of current.

The Inception of Resistors as a Distinct Electronic Component

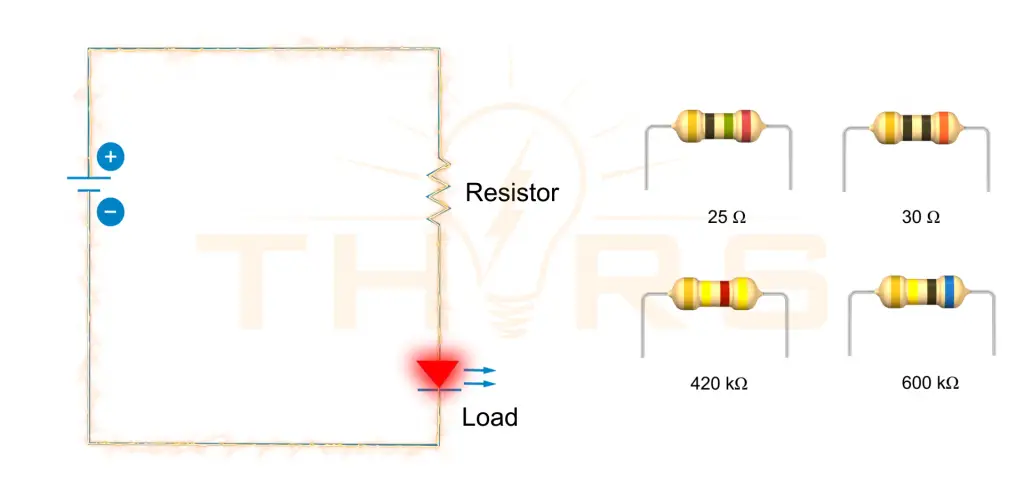

In the early 1920s, resistors began being manufactured as distinct electronic components. Carbon composition resistors, which became popular in the 1930s, were among the first produced. These resistors had cylindrical structures filled with a mixture of carbon and resin, and their resistance value depended on the carbon-to-resin ratio. Resistors use a color-coding system to convey their resistance value, tolerance, and occasionally their reliability. This system involved colored bands applied to the resistor’s body. Early models of radios and TV sets commonly used carbon composition resistors. However, they were eventually replaced by wirewound resistors due to the high noise and thermal stress caused by the material’s thermal coefficient, which modifies the resistance value as the temperature fluctuates.

Creation of Wirewound Resistors

Wirewound resistors had a core made of plastic, ceramic, or fiberglass, around which a wire was wound. These resistors were commonly used in power supplies and amplifiers due to their ability to handle high power levels. However, their large size and high cost led to the development of carbon and metal film resistors.

Modernization of Resistors

Carbon and metal film resistors were developed in the 1960s. These resistors were made by depositing thin layers of carbon or metal onto a ceramic substrate. The thickness of the deposited layer was altered to modify the resistance values. Carbon and metal film resistors were more stable than earlier types and became widely used in consumer electronics.

Later, thin layers of resistive materials were deposited on ceramic substrates to create highly precise thin film resistors for high frequency applications. In contrast, thick layers of resistive materials were used to create less precise, thick film resistors for automotive applications.

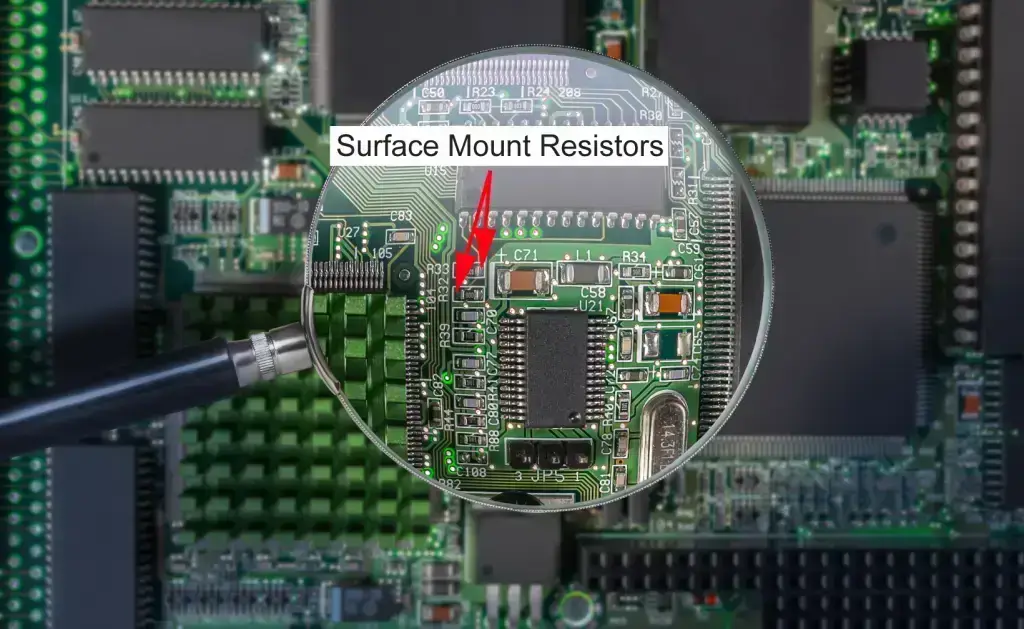

In the 1980s, resistors underwent a major shift from through-hole to surface-mount designs to accommodate the miniaturization trends needed for creating microchips. Up until this point, resistors had leads that were inserted into holes drilled in a Printed Circuit Board (PCB), which took up a significant amount of space on the PCB.

Surface mount resistors, unlike through hole counterparts, do not have leads and can be directly soldered onto the PCB, taking up very little space. Instead of color coding, which is impractical for their small size, these resistors typically feature a numerical code printed directly on their surface to specify their resistance value. Carbon film, metal film, thin film, and thick film types are all used in surface mount resistors.

The evolution of resistor technology has been essential to the advancement of modern electronics, with their continued development fueled by the need for smaller sizes, improved efficiency, and cost-effective solutions in circuit design.

Are you interested in learning more about resistors and various resistor circuits? The THORS Passive Electronic Circuit Basics course is a comprehensive e-learning module that covers not only circuits built using resistors, but also circuits built using other passive electronic components in modern electronics.