Even as we learn to live with C and its many variants, the risks in the manufacturing supply chain continue to soar due to inflation, freight management hurdles, and acute shortage of raw materials, such as semiconductors, steel, and resin. Using the production part approval process can help alleviate supply chain issues by improving the communication between the customers and the suppliers.

The “new” normal in the post-pandemic world is further unsettled by events like the Suez Canal blockage, the Russia-Ukraine War, and the sky-rocketing price of crude oil. According to Folay’s insight into the Top Legal Issues Facing the Automotive Industry in 2022, shipping cost from Asia to the has today surged in excess of 500% from 2021. With all the new and unpredictable challenges impacting the manufacturing industry, it is important for the suppliers to establish effective communication through a systemized process to eliminate any waste and to strive for continuous improvement.

What is the Production Part Approval Process?

Production Part Approval Process (PPAP) is an approval process in which the supplier seeks customer confidence in its ability to produce quality products that conform to customer requirements, produced at the specified production rate for the quoted price. The automotive industry has identified PPAP as an efficient core tool approval process to improve supplier-customer communication to establish customer confidence in the supplier’s capabilities. The ultimate industry standard for PPAP was developed by the Automotive Industry Action Group (AIAG) and is followed by automotive giants like Ford and General Motors.

What is the Purpose of PPAP?

The two purposes that are met by PPAP are the following:

- PPAP can prove that the supplier has understood the customer’s requirements.

- PPAP can prove that the supplier is capable of consistently producing products that meet the customer specifications and volume requirements during the actual production run at the quoted production rate.

How is PPAP Performed?

PPAP is primarily a submission-and-approval process. The supplier submits certain documents, test results, and records seeks customer approval. To make a PPAP submission, one must understand the different submission levels and the decisions the customer can make on the submission.

I. What are Submission Levels?

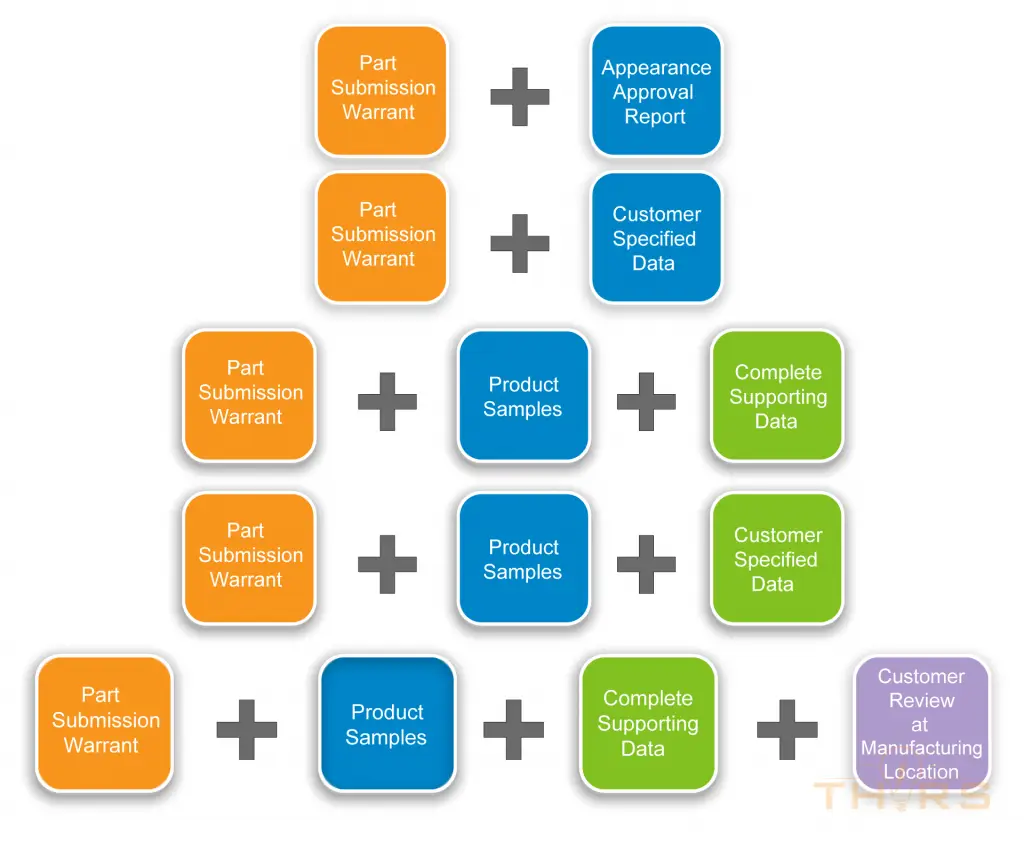

Submission levels in PPAP indicate which of the documents and records are to be submitted to the customer for approval. The submission level also indicates the customer’s confidence in the supplier’s capability. The five submission levels are: Level 1, Level 2, Level 3, Level 4, and Level 5.

Level 3 is considered the default submission level to be followed by the supplier when a level is not specified by the customer. Level 1 is associated with the highest customer confidence, while level 5 represents the lowest customer confidence. Fig. 1 is a graphical representation of the requirements of the different submission levels.

II. What are Customer Decisions?

The customer responds to a supplier’s PPAP submission with one of the following three decisions: “approved,” “interim approval,” and “rejected.”

- Approved: In a PPAP submission decision, “approved” implies that the part or the material meets all customer requirements, and the supplying organization is authorized to ship the production quantities based on the customer schedule.

- Interim Approval: In a PPAP submission decision, “interim approval” implies that the supplying organization has been permitted to ship the part or material for the customer’s production requirements on a limited time or limited quantity basis.

- Rejected: In a PPAP submission decision, “rejected” implies that the submission does not meet the customer requirements based on the production lot data or the accompanying documentation. In this case, the supplying organization is required to correct the submission or the process as appropriate to ensure that the customer requirements are met and then repeat the PPAP submission.

What makes Production Part Approval Process an essential tool?

PPAP was developed for use in the automotive industry. However, due to its effectiveness, today it finds is applied to many industries like aerospace, solar power plants, and oil and gas. The three aspects that make PPAP an essential tool for supplier-customer communication are the following:

- Covers All Aspects: PPAP consolidates all necessary test records and documents related to the product, process, and tooling, along with records of quality, standards, and proof for meeting customer requirements. As a result, PPAP is a documentation of all aspects that need the customer’s attention.

- Communication at the Right Time: PPAP is submitted after a significant production run and before bulk production. This ensures that there is objective evidence of the supplier’s capability to meet customer expectations prior to actual production.

- Customizable: The customer can decide what documents need to be included in a PPAP submission. This makes PPAP a flexible process. As a result, it can be adopted and adapted by any industry.

Why use PPAP?

Preparing a PPAP submission can be a tedious and daunting process, but as the British music composer, John Powell, notes, “communication works for those who work at it.” Learn all about the PPAP development process, submission levels, and PPAP documents in the Production Part Approval Process course brought to you by THORS eLearning Solutions. Our comprehensive and visually engaging course with its knowledge-oriented assessment tools can help you become competent in developing an effective PPAP submission for your organization.

In part two of this series, we discuss the Elements of the PPAP Package.