Course Description

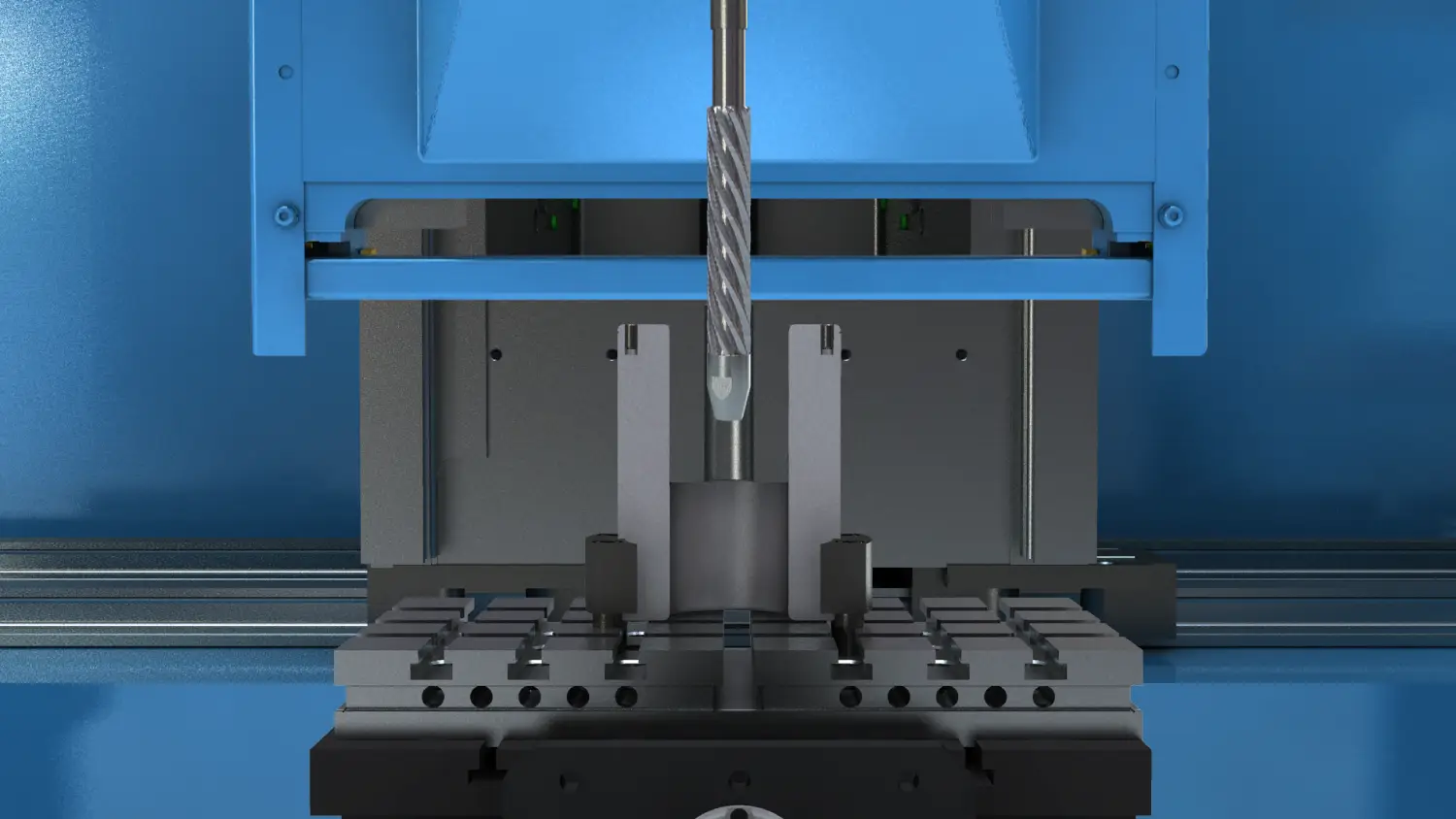

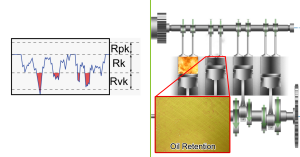

The THORS Honing Video Series 2 course introduces learners to the concepts that are important to the honing process, such as the process parameters, process steps carried out, bore measurements, bore measuring instruments, and the finish parameters. In addition, the series explores the important safety, best practices, and troubleshooting techniques for the honing operators and the process.

Who will benefit from this Honing video series?

Operators, Inspectors, Sales, and Purchasing.

Course Classification

*THORS uses the Bloom’s Taxonomy Methodology for our course development.

Certificate Awarded for Honing Video Series 2

*upon successful completion

Related Posts

Upskilling in the Manufacturing Industry with THORS

In today’s rapidly evolving manufacturing industry, staying up to date with the latest technologies and processes is crucial to remaining competitive. Upskilling in the manufacturing industry

Why Digital Assessment Tools for Hiring are Essential

Hiring the right person for a technical position is crucial for the success of any organization. However, what happens when a new hire lacks the

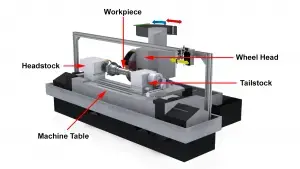

Gear Hobbing Cutting Parameters to Optimize the Hobbing Process

What are the Primary Gear Hobbing Cutting Parameters? Primary gear hobbing cutting parameters include the radial feed rate, the axial feed rate, the work spindle