Course Description

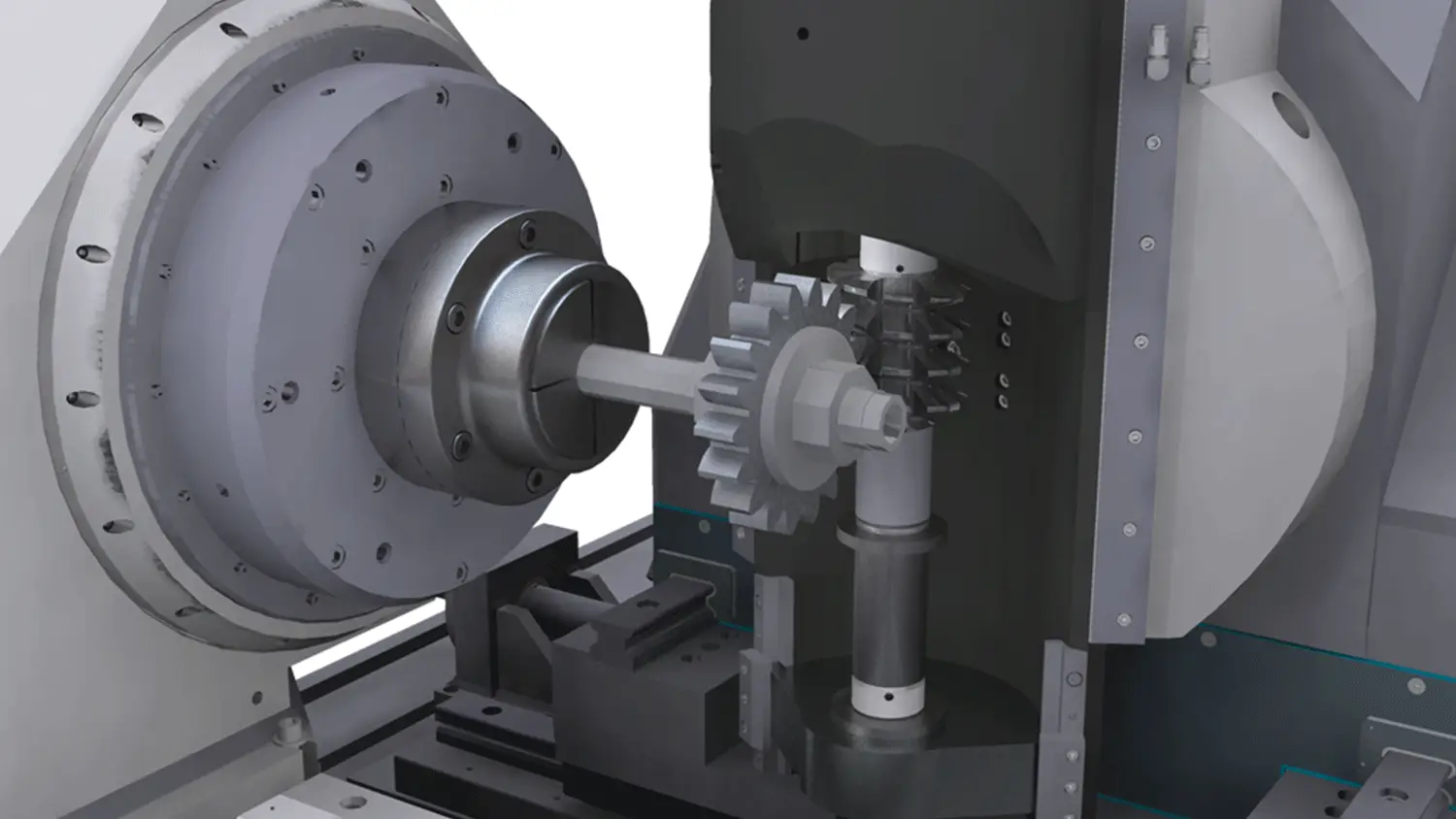

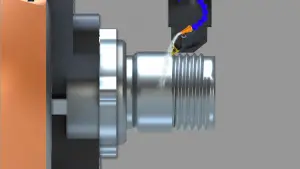

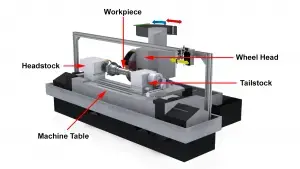

The Gear Hobbing Video Series 2 course introduces learners to a basic setup sheet for the hobbing process and addresses important concepts, such as cutting parameters and Human Machine Interface (HMI) programming. Finally, some crucial best practices and troubleshooting techniques for gear hobbing machines are presented.

Who will benefit from this Gear Hobbing setup and programming video series?

Operators, Inspectors, Sales, and Purchasing.

Course Classification

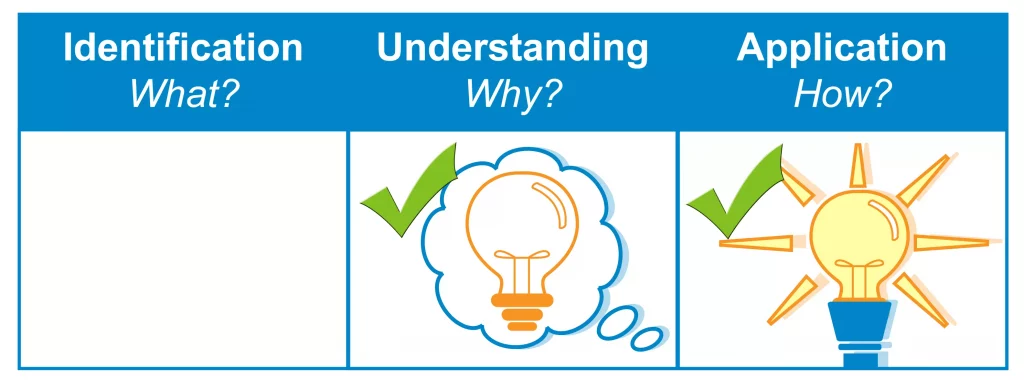

*THORS uses the Bloom’s Taxonomy Methodology for our course development.

Certificate Awarded for Gear Hobbing Video Series 2

*upon successful completion

Related Posts

The Essential Skills of Modern Purchasing Professionals

In my professional career that spans more than three decades, I have had the privilege of working closely with purchasing. I can attest to the

How Can THORS Help Enhance Your College Education?

THORS Academy can help enhance your college education in a number of ways. Imagine being in a college class and being told you have a

Cross-Cultural Training Benefits

Understanding Cross-Cultural Training In today’s interconnected world, businesses are expanding beyond borders. To thrive globally, organizations must equip their employees with cross-cultural skills. Cross-cultural training